Signal device of error action anti-collision detector for machine table or equipment working head

A detection device and work head technology, applied in the field of signal devices, can solve problems such as damage to work heads or objects to be processed, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

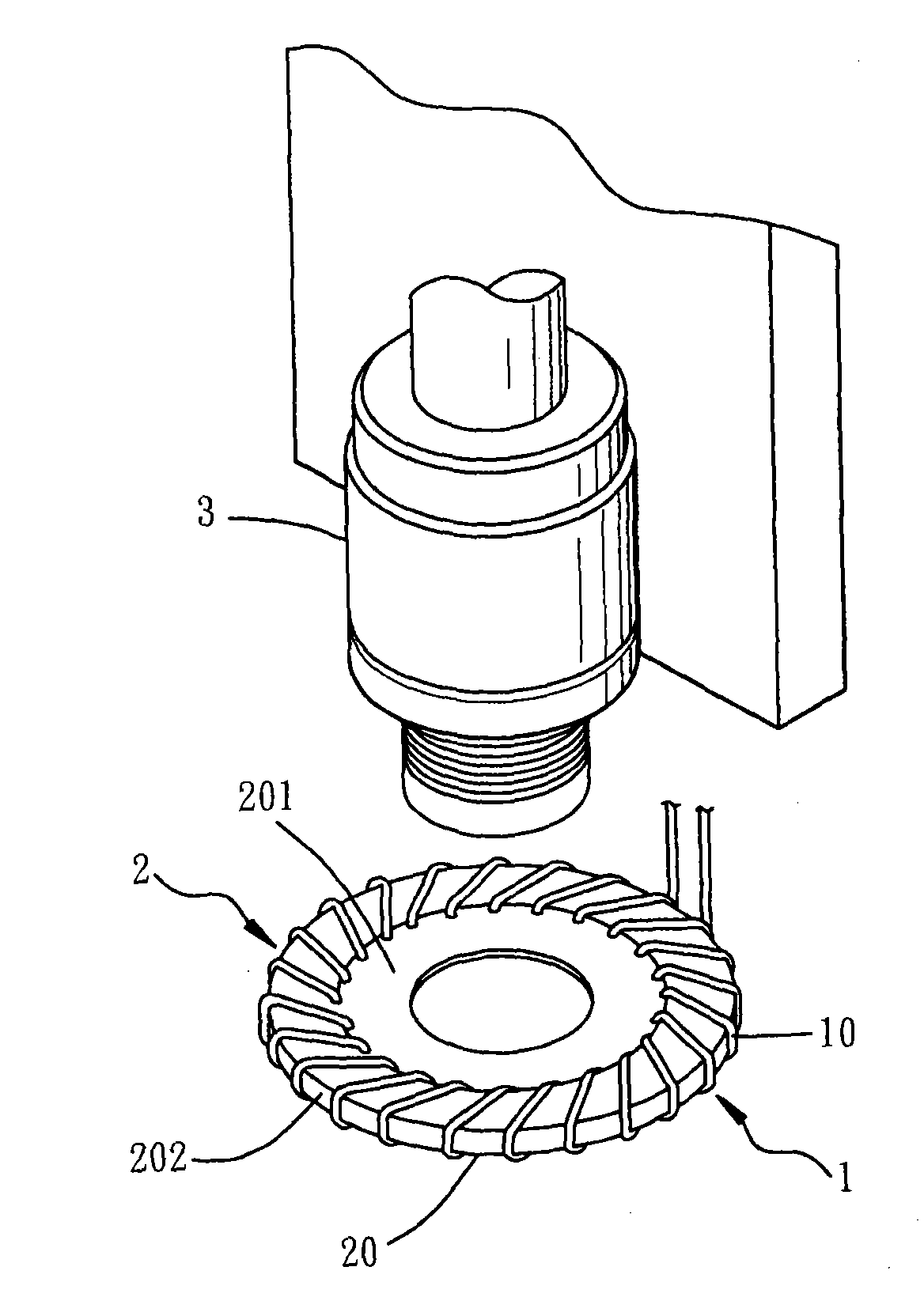

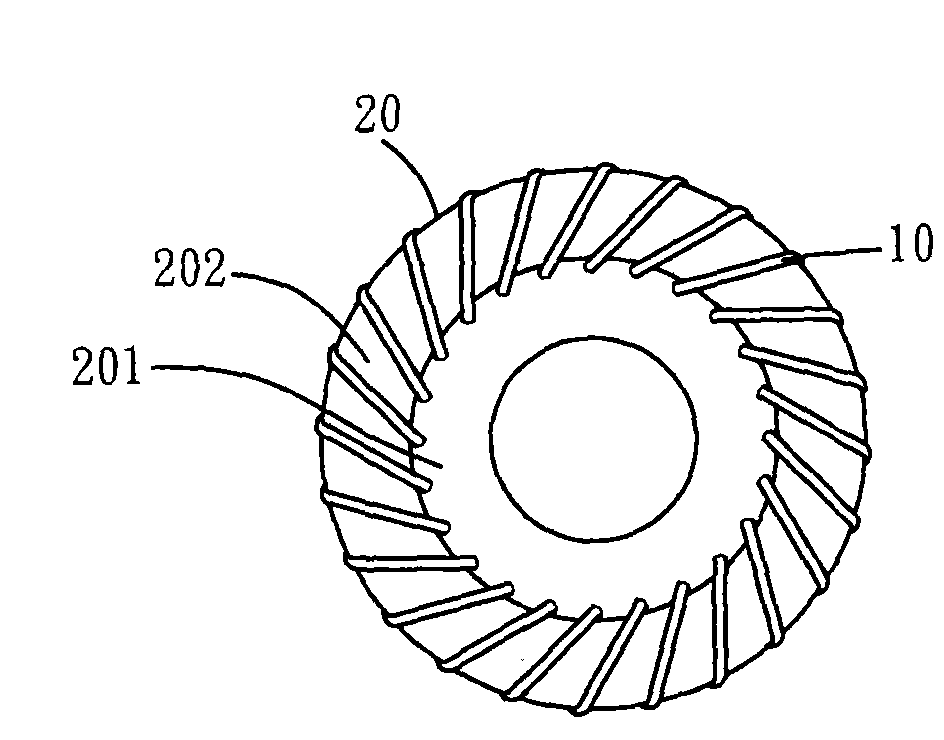

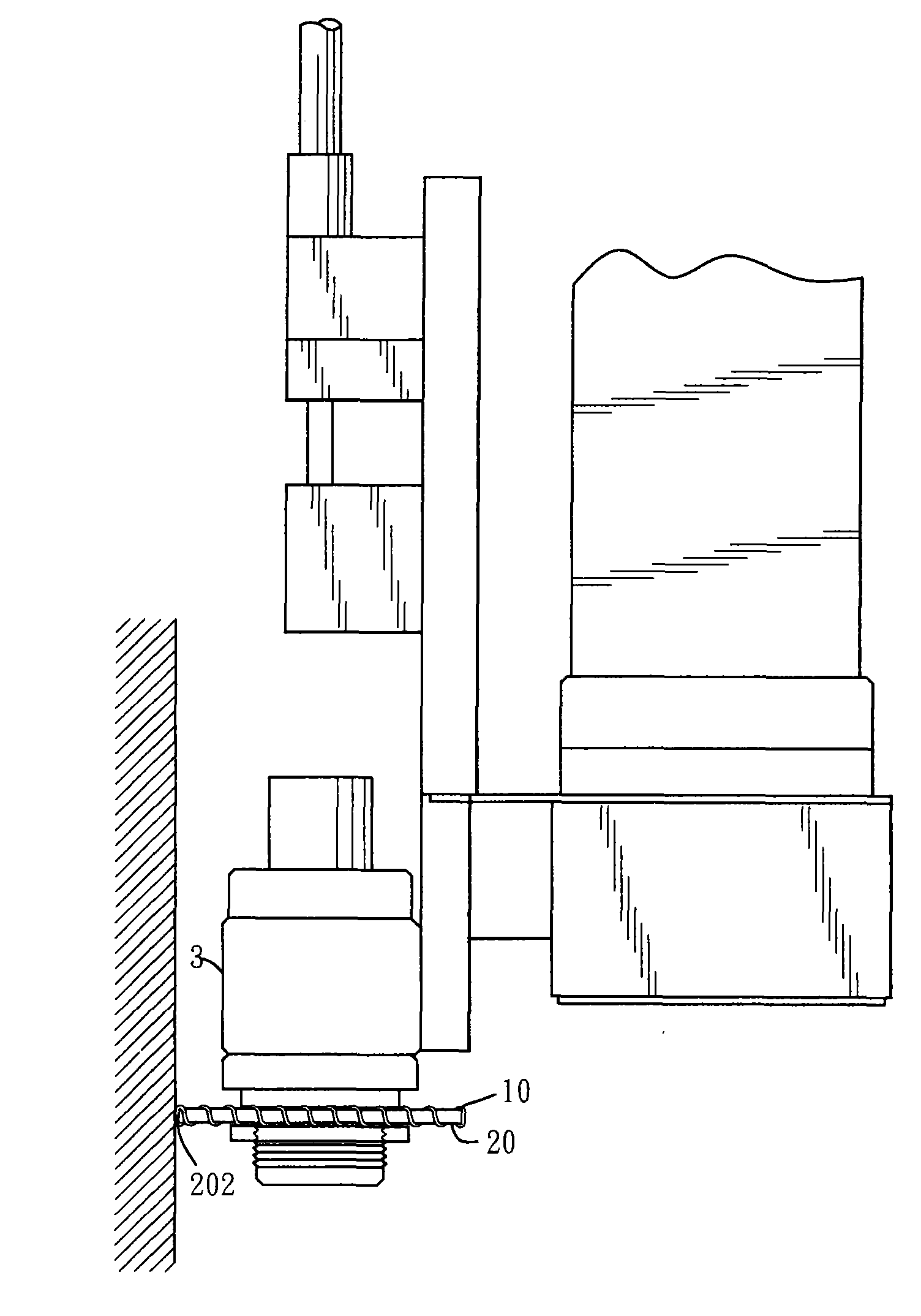

[0040] The present invention relates to an annunciator for a machine or equipment working head misoperation anti-collision detection device, including a control mechanism 1 and a flexible sensing mechanism 2, the sensing mechanism 2 is arranged around various machines On the working head 3, there is an elastic buffer mechanism between the control mechanism 1;

[0041] The control mechanism 1 and the sensing mechanism 2 are assembled and cooperate with each other to form a normal state. When the sensing mechanism 2 touches a foreign object due to the displacement action of the working head 3, it will change from the normal state to a variable state, and the state will be changed according to the state. The change is used as a signal to prompt the misoperation anti-collision detection device. At the same time, the sensing mechanism 2 generates an elastic buffer due to contact with foreign objects to prevent the working head 3 from colliding, and uses the elastic buffering process...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com