Reverse inclined air curtain type air exhaust cabinet

A technology for exhaust cabinets and air curtains, which is applied in the directions of removing smoke and dust, cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems of leakage of polluted gas in the cabinet, increase in inhalation, leakage of pollutants, etc., and save consumption. , the effect of reducing leakage and enhancing the ability to disturb airflow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

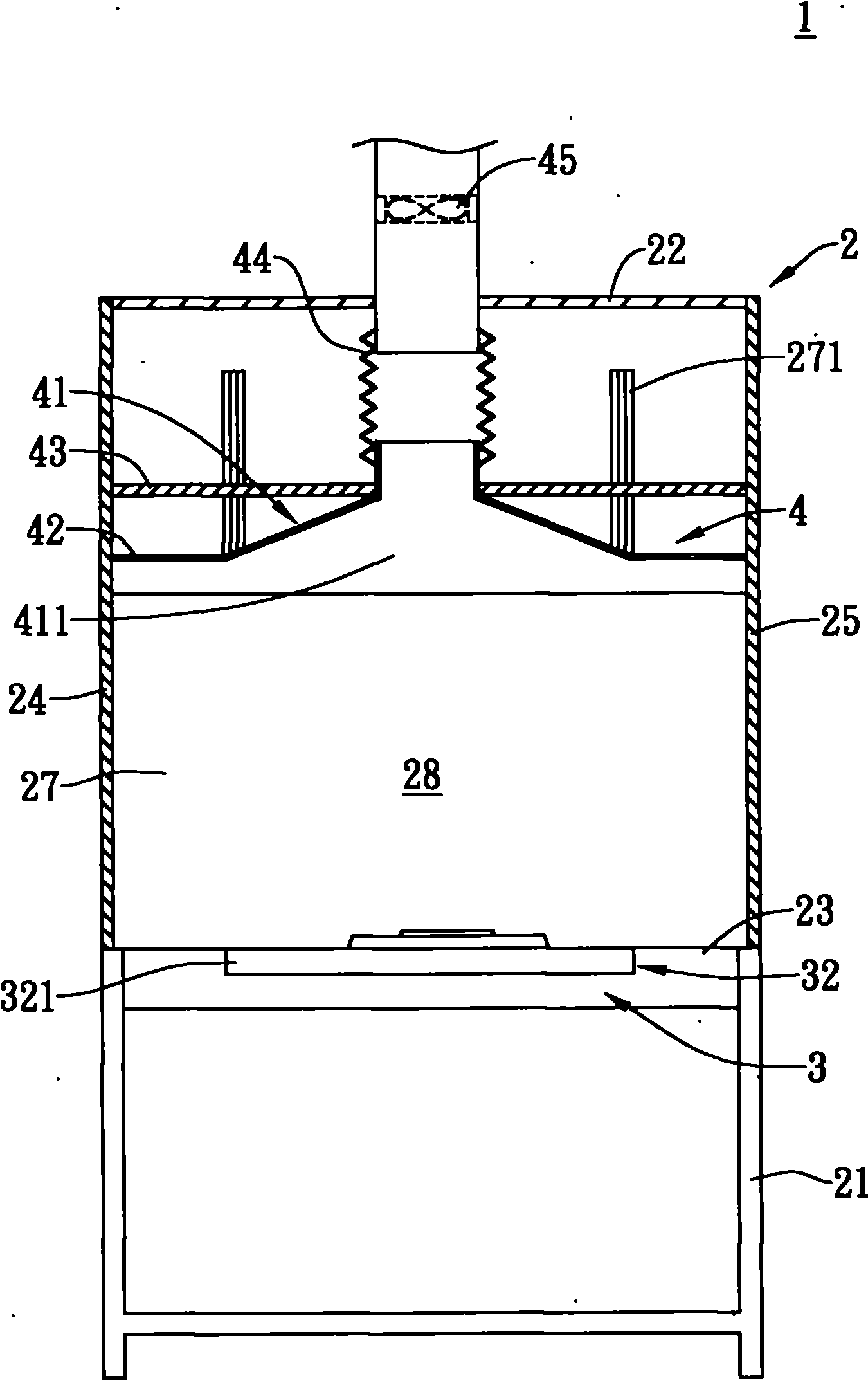

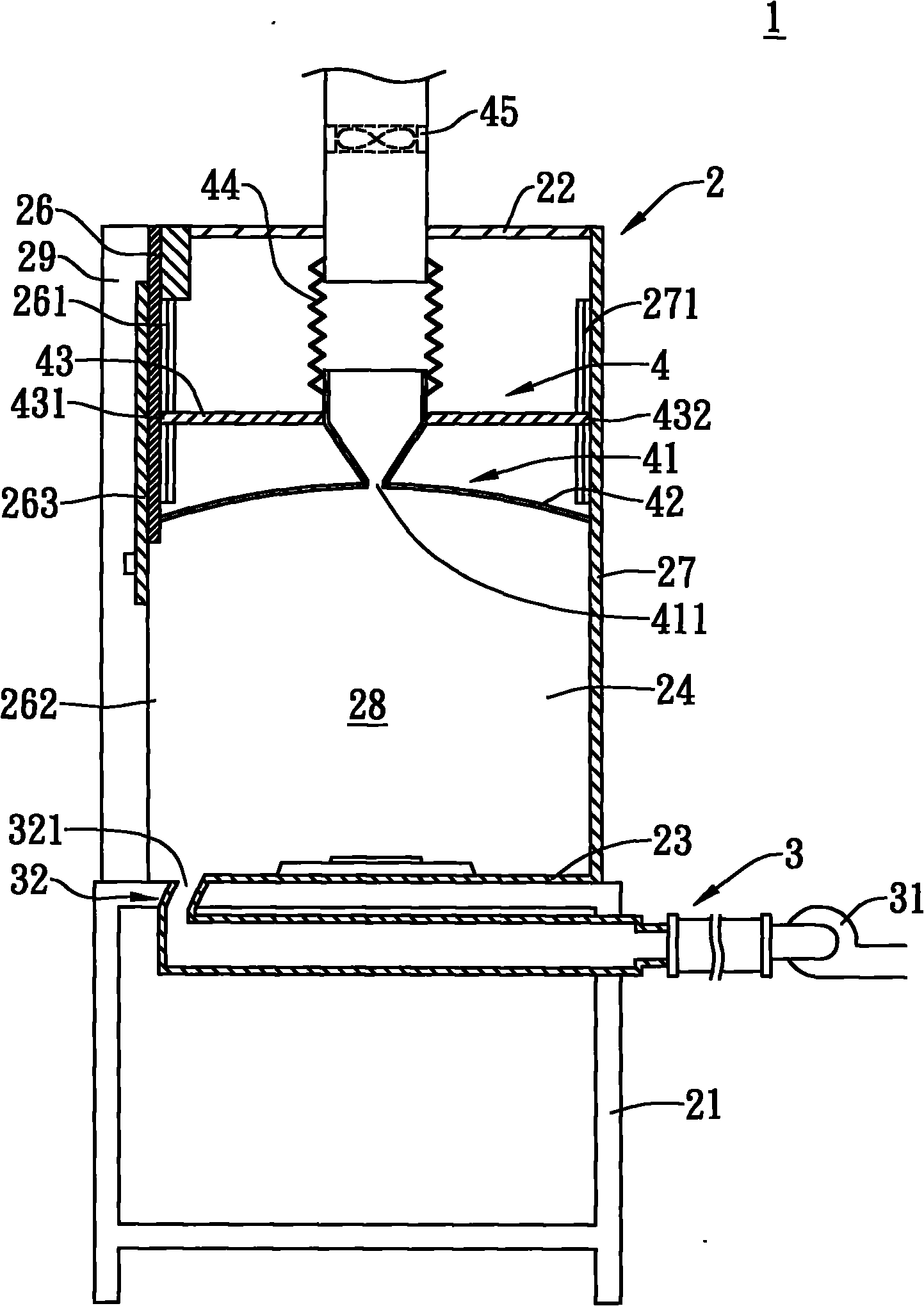

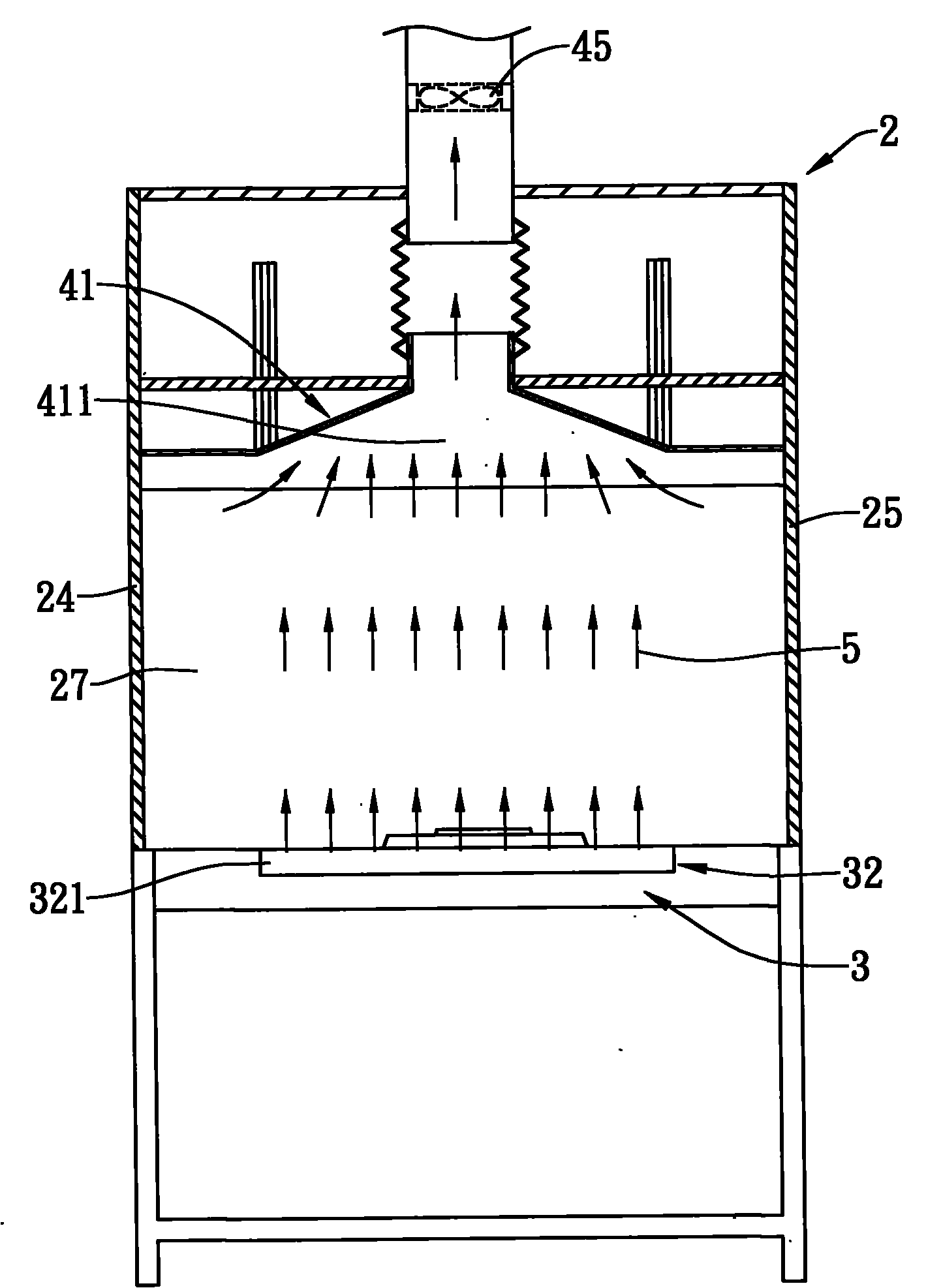

[0027] see figure 1 , figure 2 As shown, it is the first embodiment of the reverse inclined air curtain type exhaust cabinet 1 of the present invention, which includes an operation cabinet 2 , an elongated blowing device 3 and a suction hood 4 .

[0028] The operating cabinet 2 is roughly in the shape of a cuboid, and a locker 21 with legs is provided below it to support the operating cabinet 2 upwards and store objects. The operating cabinet 2 includes a top board 22, a bottom board 23, a left side board 24, A right side panel 25 , a front panel 26 and a rear panel 27 , each panel is combined to form an accommodating space 28 inside the operation cabinet 2 . Wherein, the front board 26 and the rear board 27 are respectively provided with a track 261 , 271 . The left and right sides of the front end of the operation cabinet 2 are respectively provided with columns 29 to respectively fix the left and right sides of the front plate 26 and form an opening 262 under the front ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com