Method for regulating mechanical property of polypropylene based on alpha/beta complex nucleating agent

A technology of composite nucleating agent and polypropylene mechanics, which is applied in the field of polypropylene, can solve the problems of decreased tensile and bending properties, and decreased rigidity, so as to achieve the effect of improving tensile strength and avoiding processing tests

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

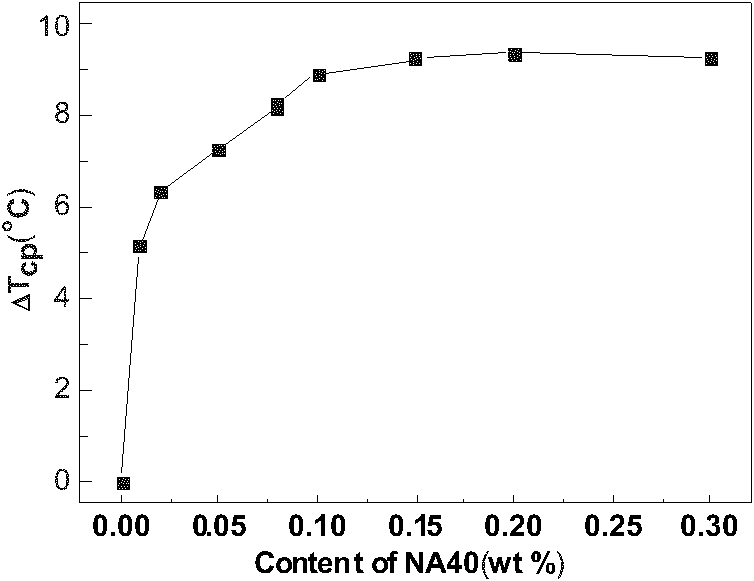

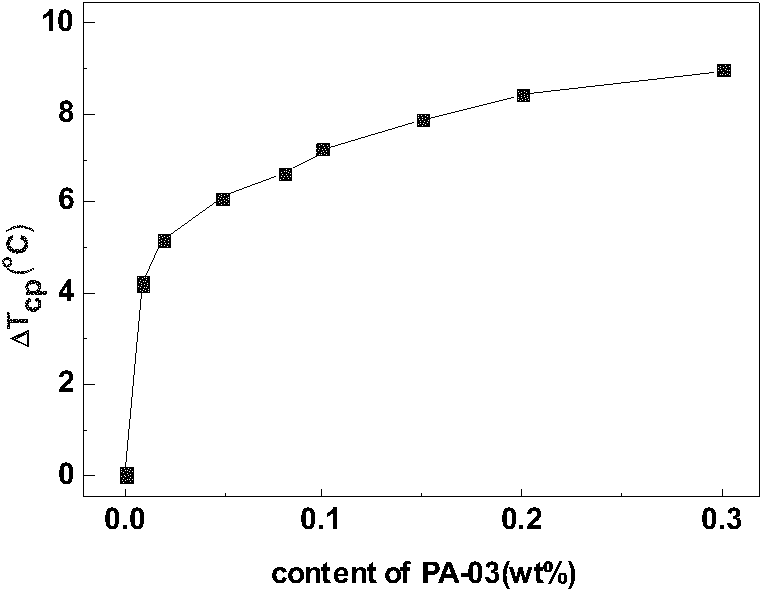

[0030] (1) Select a polypropylene α crystal nucleating agent NA40 and a polypropylene β crystal nucleating agent PA-03; respectively test the influence of the addition concentration of the two on the crystallization temperature of polypropylene, which is recorded as ΔT Cp . See figure 1 , figure 2 ;

[0031] (2) When the total addition concentration of the two nucleating agents is 0.2wt%, according to the ΔT corresponding to the respective addition concentrations of the two nucleating agents Cp , calculate the difference between the two under each composite ratio, and record it as ΔT Cαβ , pick T Cαβ The ratio with the smallest absolute value, NA40:PA-03=3:7 (mass ratio), is the best ratio when the total concentration of the two nucleating agents is 0.2wt%.

[0032] Table 1 ΔT of NA40 / PA-03 in different proportions in polypropylene when the total concentration is 0.2wt% Cαβ Compare

[0033]

[0034] (3) Mix 0.6g NA40 with 1.4g PA-03, add 1000g polypropylene.

Embodiment 2

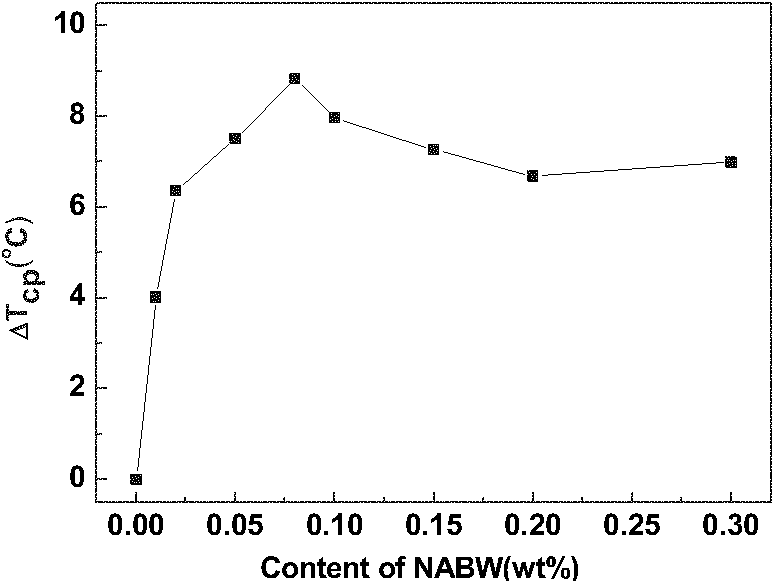

[0036] (1) Select a polypropylene α-crystal nucleating agent NA40 and a polypropylene β-crystal nucleating agent NABW, respectively test the influence of the addition concentration of the two on the crystallization temperature of polypropylene, denoted as ΔT Cp . See figure 1 , image 3 ;

[0037] (2) When the total addition concentration of the two nucleating agents is 0.2wt%, according to the ΔT corresponding to the respective addition concentrations of the two nucleating agents Cp , calculate the difference between the two under each composite ratio, and record it as ΔT Cαβ , pick ΔT Cαβ The ratio with the smallest absolute value, NA40:NABW=1:3 (mass ratio), is the best ratio when the total concentration of the two nucleating agents is 0.2wt%.

[0038] Table 2 ΔT of NA40 / NABW in polypropylene with different proportions when the total concentration is 0.2wt% Cαβ Compare

[0039]

[0040] (3) 0.5g NA40 was mixed with 1.5g NABW, and 1000g polypropylene was added.

Embodiment 3

[0042] (1) Select a polypropylene alpha crystal nucleating agent S20 and a polypropylene beta crystal nucleating agent PA-03. Test the effect of the added concentration of the two on the crystallization temperature of polypropylene, which is recorded as ΔT Cp ,See Figure 4 , figure 2 ;

[0043] (2) When the total addition concentration of the two nucleating agents is 0.3wt%, according to the ΔT corresponding to the respective addition concentrations of the two nucleating agents Cp , calculate the difference between the two under each composite ratio, and record it as ΔT Cαβ , pick ΔT Cαβ The ratio with the smallest absolute value, S20: PA-03=2: 3 (mass ratio), is the best ratio when the total addition concentration of the two nucleating agents is 0.3wt%;

[0044] Table 3 The ΔT of S20 / PA-03 in polypropylene with different proportions when the total concentration is 0.3wt% Cαβ Compare

[0045]

[0046]

[0047] (3) Mix 1.2g S20 with 1.8g PA-03, add 1000g polyprop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com