Selective hydrodesulfurization method for high-sulfur high-olefin catalytic gasoline

A technology for catalyzing gasoline and gasoline hydrogenation, which is applied in the treatment of hydrocarbon oil, hydrotreating process, petroleum industry, etc., can solve the problems of small loss of octane number, poor adaptability, single operation of fractionation unit, etc., and achieves loss of octane number. small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

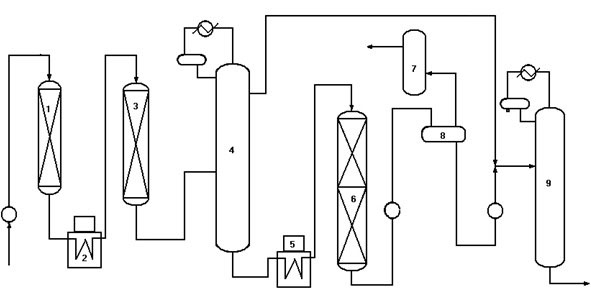

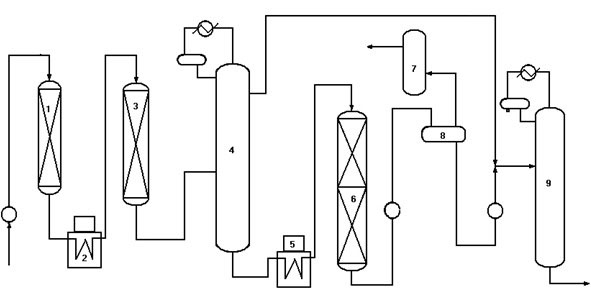

Image

Examples

Embodiment

[0042] This example shows the desulfurization effect of a high-sulfur, high-olefin catalytic cracking gasoline, and those skilled in the art can formulate specific reaction conditions according to the properties of raw materials and product quality requirements.

[0043] The catalyst is an industrialized catalyst produced by Jiangsu Jiayuxin Company.

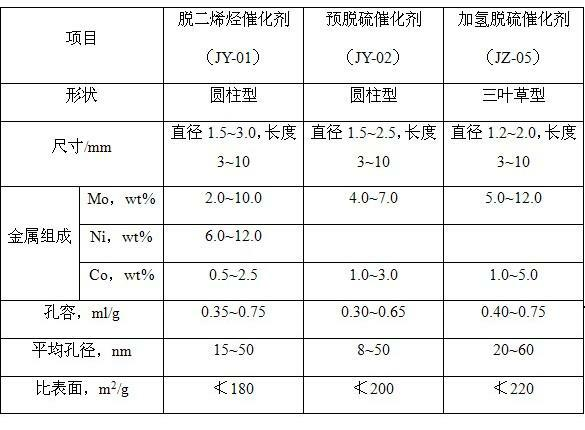

[0044] Table 1 Basic physicochemical properties of catalysts

[0045]

[0046] 1) Pre-hydrotreating of feedstock oil

[0047] The raw oil pre-hydrogenation section adopts JY-01 and JY-02 commercial catalysts produced by Jiangsu Jiayuxin Industrial Co., Ltd., and the two catalysts are respectively loaded in two reactors. The operating conditions are: hydrogen partial pressure of 2.0 Mpa, inlet reaction temperature 160°C, liquid hourly space velocity 9.0h -1 , the volume ratio of hydrogen to oil is 200, the operating conditions of the pre-desulfurization reaction are: 2.0Mpa, the inlet reaction temperature is 225°C, and the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com