Q420GJD-Z35 steel plate with thickness of less than or equal to 60 millimeters for high-rise building and production method thereof

A Q420GJD-Z35, high-rise building technology, applied in the field of steel, can solve problems such as excessive strength, substandard Z-direction performance, and low pass rate of steel mills

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

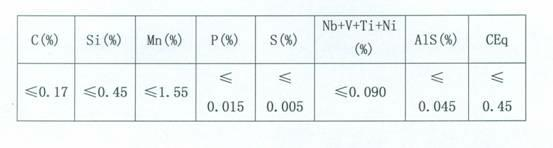

[0026] Through converter smelting, LF refining, vacuum refining, continuous casting, heating, rolling, controlled cooling, and slow cooling, the chemical composition of the Q420GJD-Z35 finished steel plate as described in Table 1 below is obtained, and the process parameters and mechanical properties are shown in Table 4 below. , 5.

[0027] Chemical composition of table 1 embodiment 1 steel

[0028]

Embodiment 2

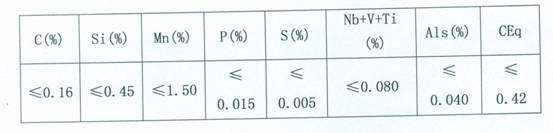

[0030] Through converter smelting, LF refining, vacuum refining, pouring, heating, rolling, controlled cooling, slow cooling, and heat treatment, the chemical composition of the Q420GJD-Z35 finished steel plate as described in Table 2 below is obtained, and the process parameters and mechanical properties are shown in Table 4 below. , 5.

[0031] Chemical composition of table 2 embodiment 2 steel

[0032]

[0033] Process flow of the present invention:

[0034] Hot metal KR deep desulfurization→converter smelting→LF refining→VD vacuum treatment→continuous casting→heating→phosphorus removal→controlled rolling→controlled cooling→controlled straightening→off-line slow cooling→heat treatment→surface inspection→finishing→flaw detection→testing → Judgment → Qualified products are put into storage.

[0035] 1.1 Steelmaking part

[0036] 1.1.1 Composition design

[0037] The chemical composition design of the steel plate of the present invention adopts low carbon equivalent, Mn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com