Oil cylinder of static pressure vibration exciter

A technology of exciter and oil cylinder, which is applied in the direction of fluid pressure actuating device, fluid pressure actuating system components, mechanical equipment, etc., can solve the problem of the increase of external leakage of the hydraulic system, the decrease of the lateral force resistance of the piston rod, and the poor test repeatability. and other problems, to achieve the effect of low power consumption, good accuracy retention and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in detail below in conjunction with the accompanying drawings.

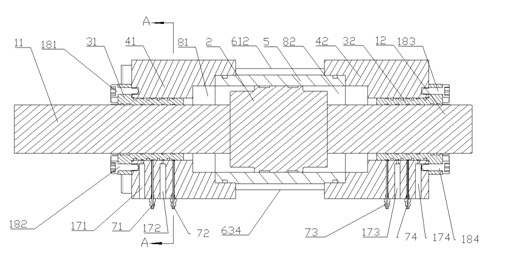

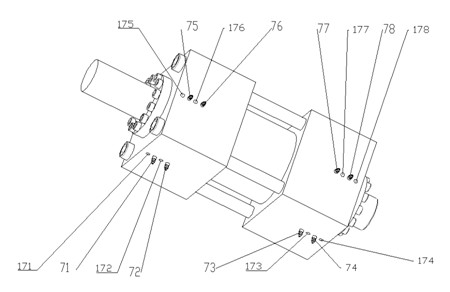

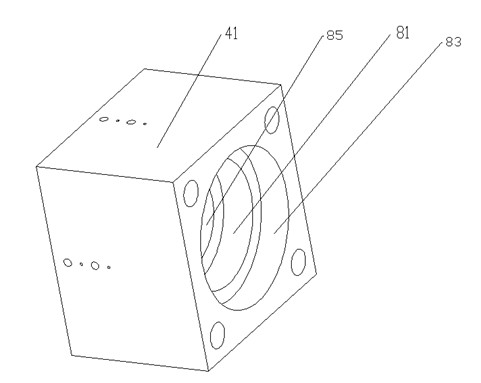

[0017] Such as Figure 1 to Figure 7 As shown, the hydrostatic vibration exciter cylinder of the present invention includes a cylinder 5 and a piston 2 placed in the inner cavity of the cylinder. Two seals are adopted between the cylinder barrel 5 and the piston 2, which can significantly improve the sealing effect. Both ends of the piston 2 are respectively fixedly connected with a piston rod 11 and a piston rod 12, and the piston rod 11 and the piston rod 12 are respectively fixedly connected with the piston 2 in a threaded manner, and the piston rod 11 and the piston rod 12 extend out of the cylinder 5 respectively. cavity. The hydrostatic bearing 31 is fixedly connected to the end cover 41 through bolts 181 and 182 ; the hydrostatic bearing 32 is fixedly connected to the end cover 42 through bolts 183 and 184 . Such as Figure 5 As shown, the cross-sections o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com