Sound surface wave measuring sensor and parameter analytical method

A technology for measuring sensors and surface acoustic waves, which is used in measuring devices, measuring heat, and transmitting sensing components using wave/particle radiation devices. and other problems, to achieve the effect of ensuring large-scale and high-precision, simple structure, and solving large-scale accurate detection of physical quantities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

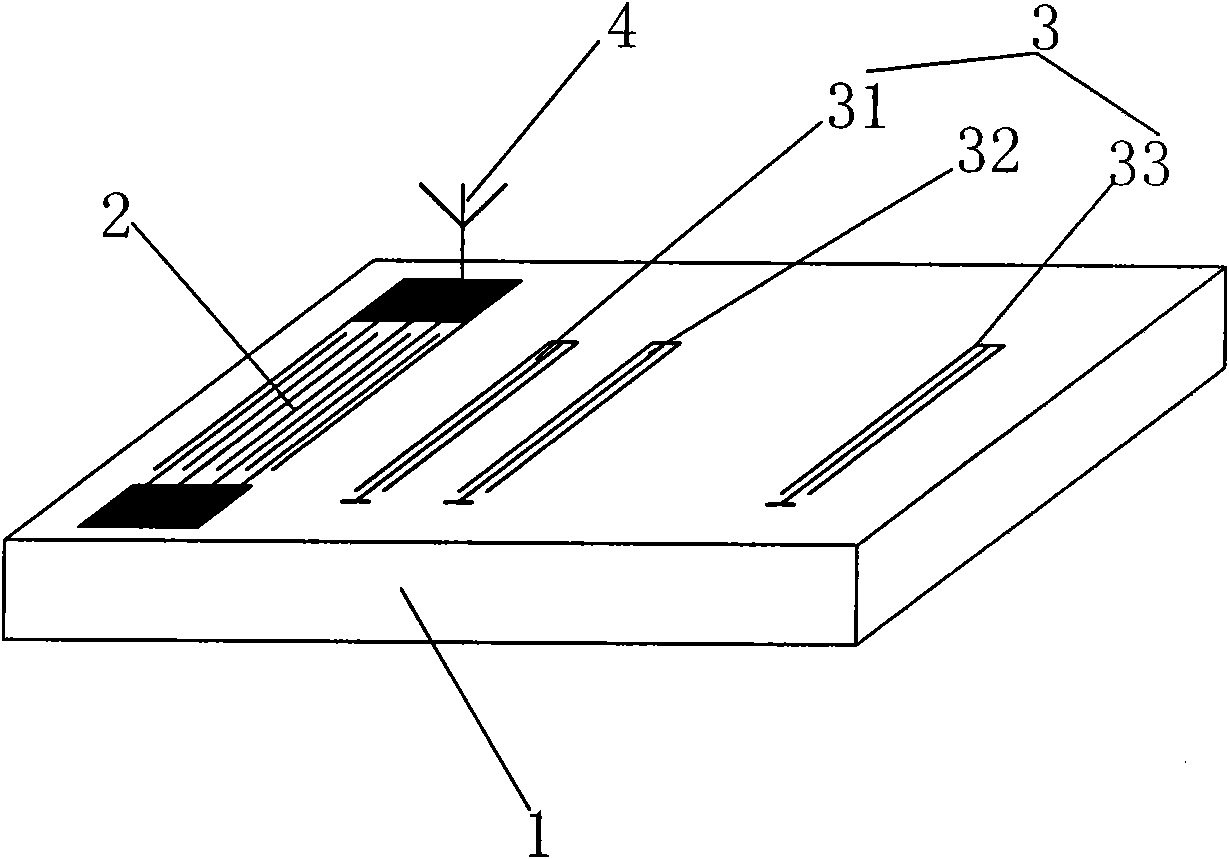

[0026] Such as figure 1 As shown, the present invention discloses a surface acoustic wave measurement sensor, which includes: a piezoelectric substrate 1, an interdigital transducer 2, a reflector 3 and an antenna 4, wherein;

[0027] Piezoelectric substrate 1, which is the sensing mechanism of the physical quantity to be measured, its thickness can be different according to the type and range of the physical quantity to be detected (such as the size of pressure, the range of temperature), by selecting different thicknesses to be processed during design Wafers are adjusted accordingly. The piezoelectric substrate 1 is made of a wafer material with piezoelectric properties. In this embodiment, the wafer material is a lithium niobate piezoelectric crystal slice in the Y-cut Z direction.

[0028] The interdigital transducer 2 and the reflector 3 are depo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com