Miniature specimen creep test system and test method

A creep test and micro-sample technology, which is applied in the field of micro-sample creep test system to improve the overall accuracy, ensure the measurement accuracy, and facilitate processing and installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

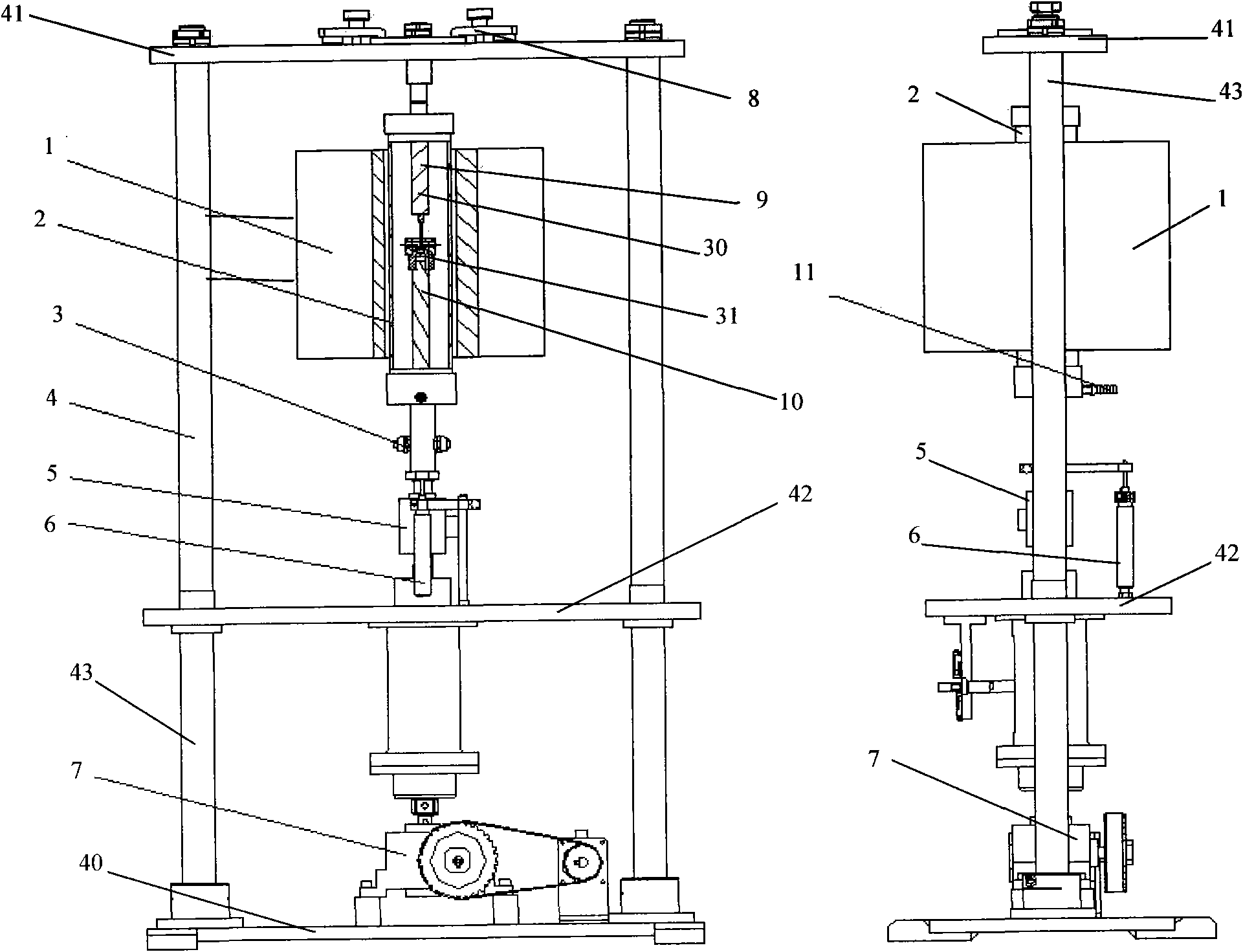

[0051] Embodiment 1 micro sample creep test system

[0052] Such as figure 1 As shown, the micro-sample creep test system of the present invention includes a main frame 4, a high temperature furnace 1, a servo motor loading device 7, a distance measuring device, a force measuring device, a cooling system 3, a gas supply device (not shown), Clamping mechanism 30, quartz tube 2.

[0053] The main frame 4 is composed of a base 40 , an upper beam 41 , a middle beam 42 and two columns 43 .

[0054] The servo motor loading device 7 is placed under the middle beam 42 , and its lower end is fixed on the base 40 . The upper end passes through the middle beam 42 . The servo motor drives the reducer through the synchronous belt, the reducer drives the lead screw, and the lead screw nut drives the lower rod to move axially through the pull tube, which can be used for compression-compression fatigue tests. force device. In order to ensure the coaxiality of the upper and lower sides, the...

Embodiment 2

[0061] Embodiment 2 micro sample creep test system

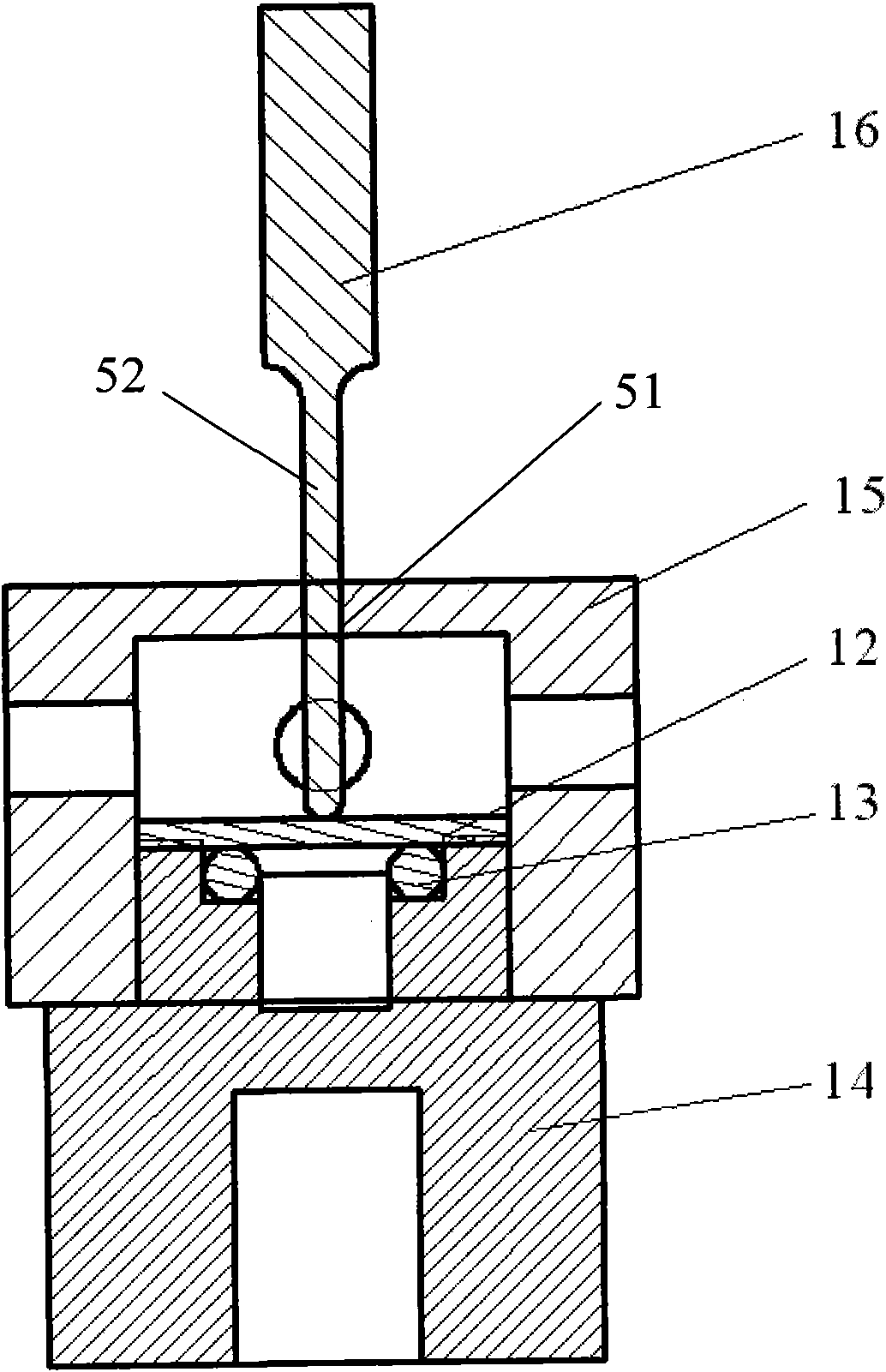

[0062] In this embodiment, the micro-sample creep test system is basically the same as that in Embodiment 1, the only difference is that the fixture set is a four-point bending fixture set, and the structure is as follows Figure 5 shown. The four-point bending fixture kit can realize the theoretical model of four-point bending with high precision and full contact with the ambient gas. The structure is basically the same as the three-point bending fixture kit, such as Figure 6 As shown, the difference is that the pressure rod and the positioning sleeve have two rectangular holes 51 in the middle of the four-point bending positioning sleeve 17, and the pressure rod 18 has two pressure heads 52.

Embodiment 3

[0063] Embodiment 3 micro sample creep test system

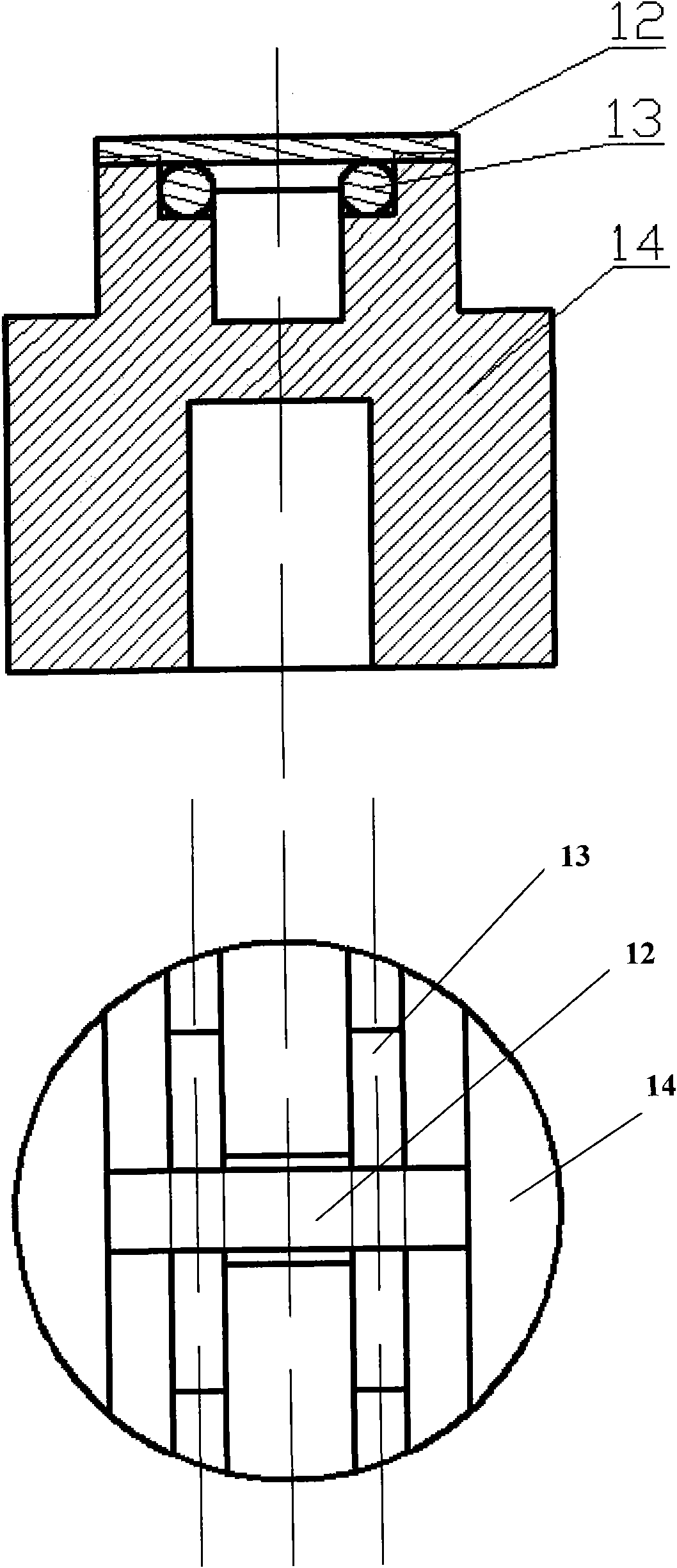

[0064] The micro-sample creep test system in this embodiment is basically the same as that in Embodiment 1, except that the fixture set is a small punching fixture set. Such as Figure 7 As shown, the feature of the small punching fixture kit is that the upper die 21 and the lower die 23 are threaded, and the small punching sample 22 is well fixed between the upper die 21 and the lower die 23, and on the side of the lower die 23 There are small holes, so that the lower surface of the sample 22 can fully contact with the ambient gas, which is convenient for studying the influence of environment and creep coupling.

[0065] Small punching lower die 23 is circular, and there is a shallow circular concave hole in the middle, which is used to place small punching sample 22, and the other end has internal thread, which can be connected with lower support rod 10. There are small holes on the side of the lower mold 23, so that the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com