Torsional vibration damper

A torsional vibration damper, torsional vibration damping technology, applied in the direction of spring/shock absorber, rotational vibration suppression, vibration suppression adjustment, etc., can solve the problems of unsatisfactory buffer characteristics, cost, complex manufacturing technology, etc., Achieving the effect of excellent cushioning properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

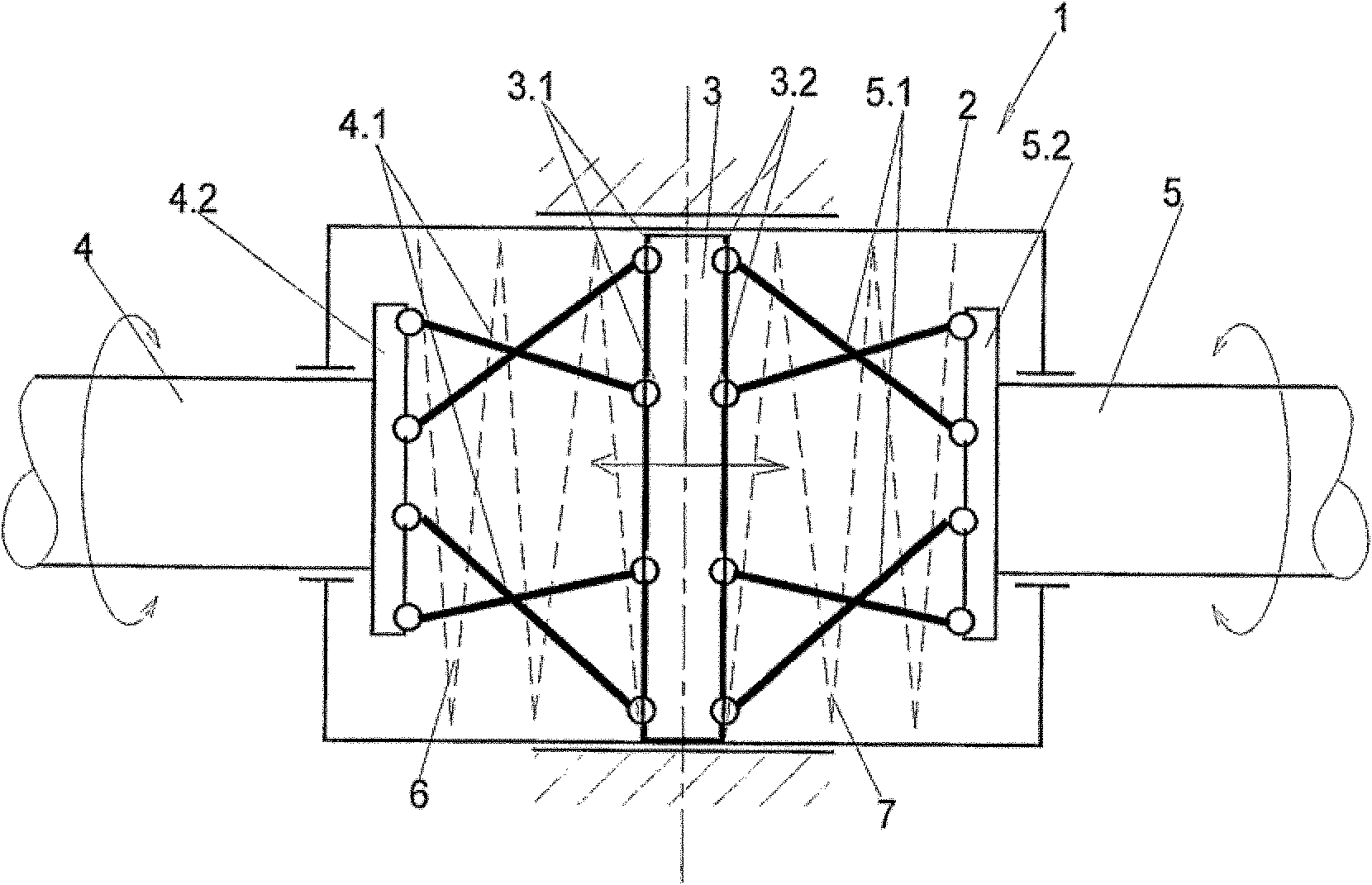

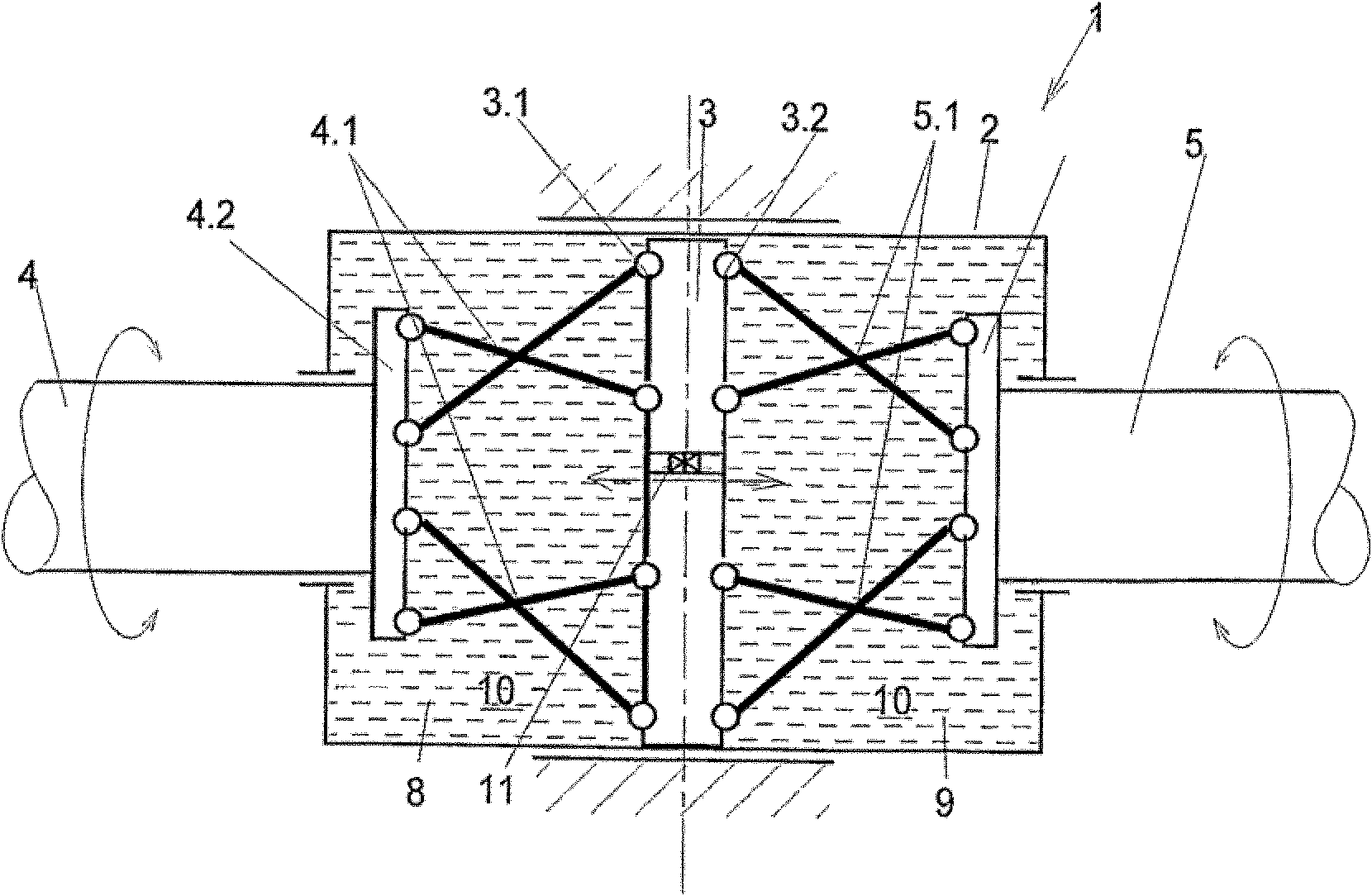

[0029] Through coupling elements 5.1, 5.2 and springs 6, 7 ( figure 1 ) or buffer medium 10 ( figure 2 ) elasticity, the torsional vibration is damped between the first element 4 and the second element 5, and the torque peak is reduced. According to an embodiment not shown, for example, the housing as the first or second element can also be designed rotatably, and for example a stub shaft can be fastened to the housing. The housing is of course not mounted fixedly relative to the base in this case.

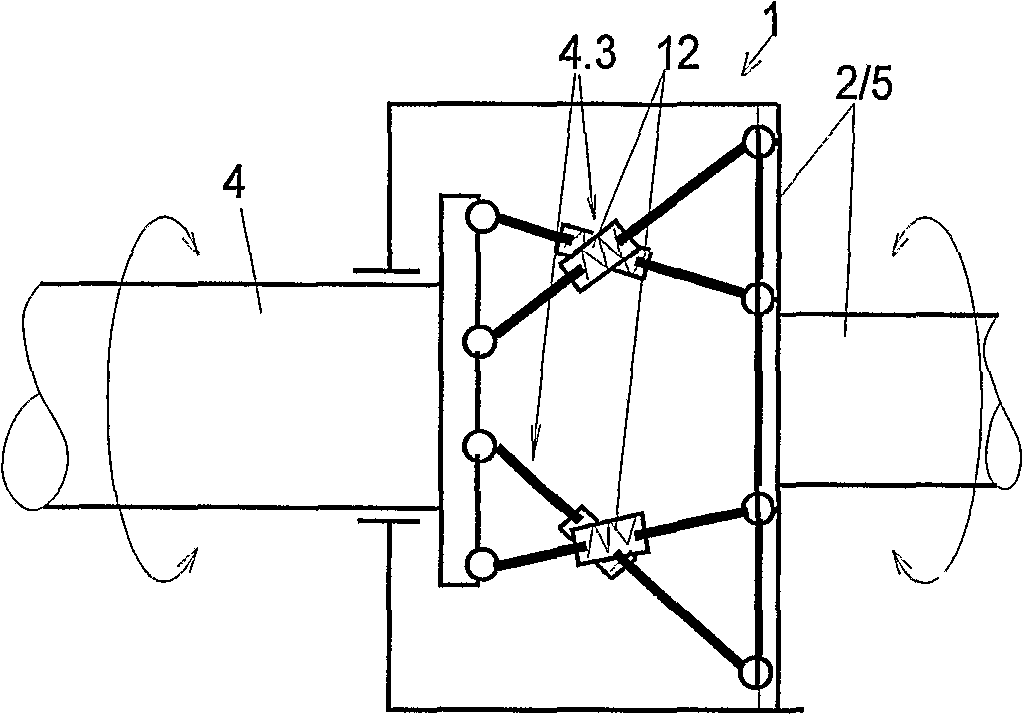

[0030] exist image 3 and 4 A variant of the damping element 1 is shown in , in which the first element 4 is formed in the form of a first axis of rotation and the second element 5 , which is rotatable relative to the first element, is the housing 2 .

[0031] according to image 3The respective third coupling element 4.3 is fastened pivotably on the receptacle 4.2 of the first element 4 and on the receptacle 5.2 of the second element 5. These third elements 4 . During rel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com