Container for packaging nuclear waste with force-fitted lid

A container and solid waste technology, applied in the direction of portable protective containers, caps, pressure vessels, etc., can solve the problems of deterioration, damage, and impact on long-term storage safety, and achieve the effect of ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

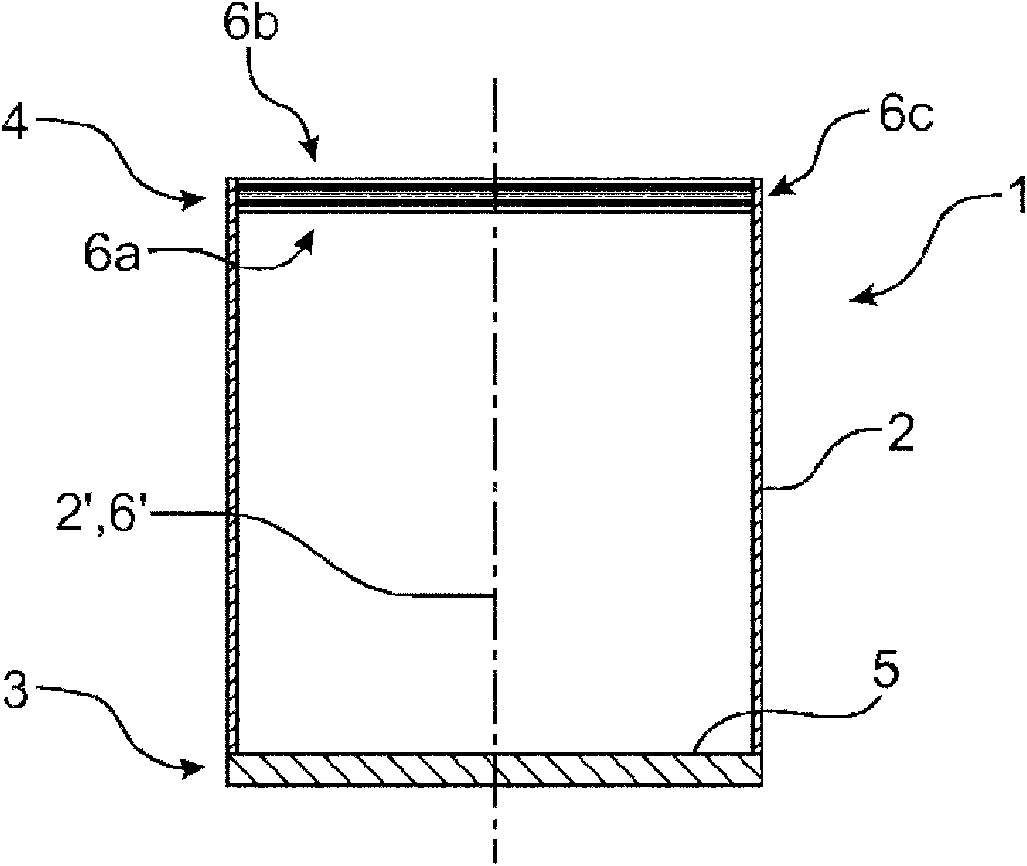

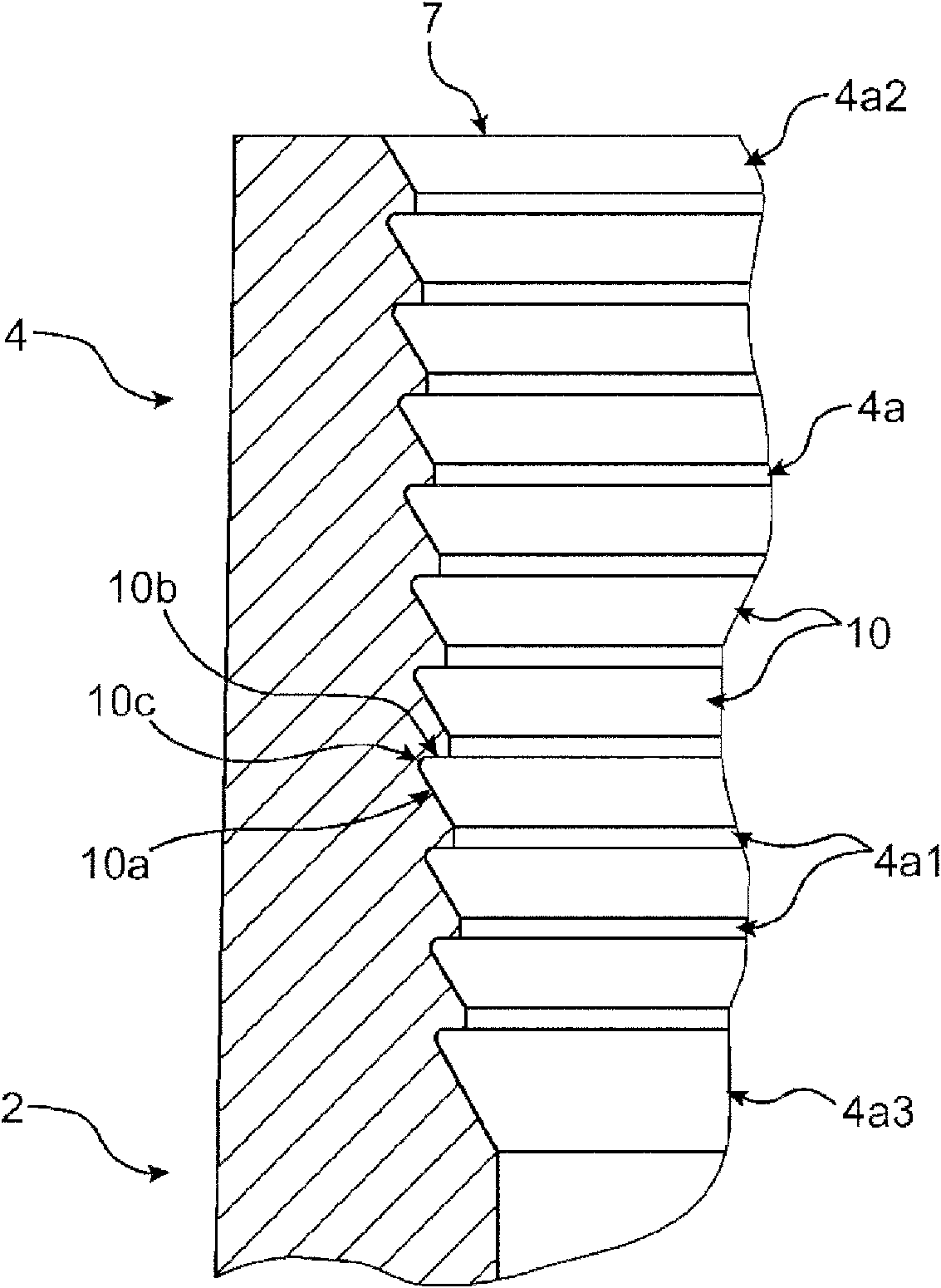

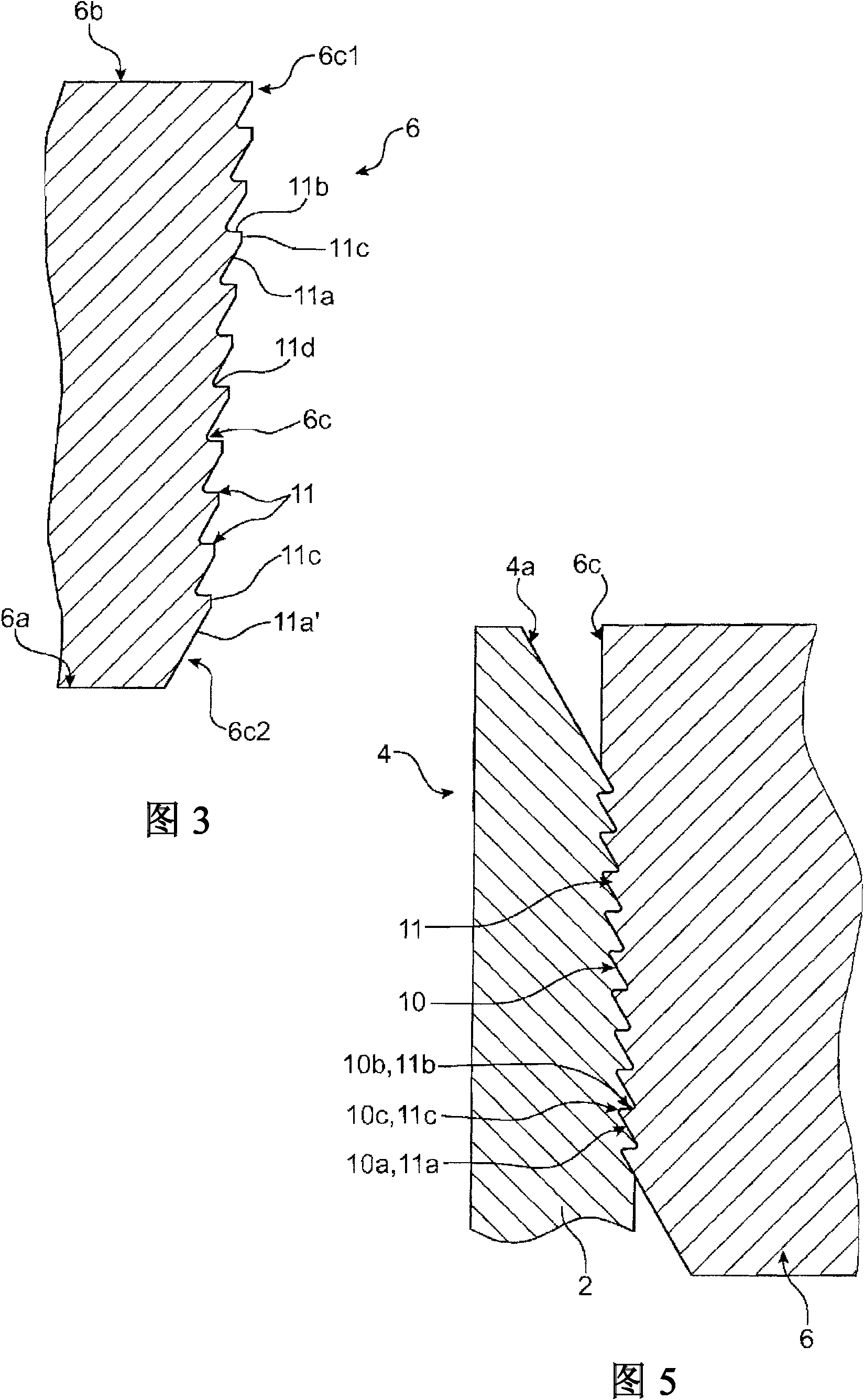

[0036] figure 1 The illustrated container 1 is particularly suitable for waste materials which tend to increase or recover in volume over time. The container 1 is also particularly suitable for enclosing stacked compressed blocks of radioactive waste. Such as figure 1 As shown, the container 1 is generally in the shape of a cylindrical barrel. It comprises a cylindrical side wall 2 having two end edges, an upper end edge 3 and a lower end edge 4, each of which has a circular closing member 5 and 6, the lower closing member forming the bottom member, the upper The closure member forms a lid. Here, the bottom member 5 is fixed non-removably to the side wall 2, for example by welding or crimping. The cover member 6 is a built-in type. The cover member comprises two surfaces: an inner surface 6a and an outer surface 6b, connected by a peripheral profile 6c. The lid 6 closes the upper opening 7 ( figure 2 or visible in FIG. 4 ); as explained later, through this upper openin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com