Method for using constraint bonded-bridge type artificial tooth

A technology for bonding bridges and dentures, applied in dentures and other directions, can solve the problems of high quality requirements of clinicians for tooth preparation, damage to abutment and occlusal relationship, food impaction and chewing function, etc., to ensure the physiological stimulation effect, Easy to master, less abutment preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

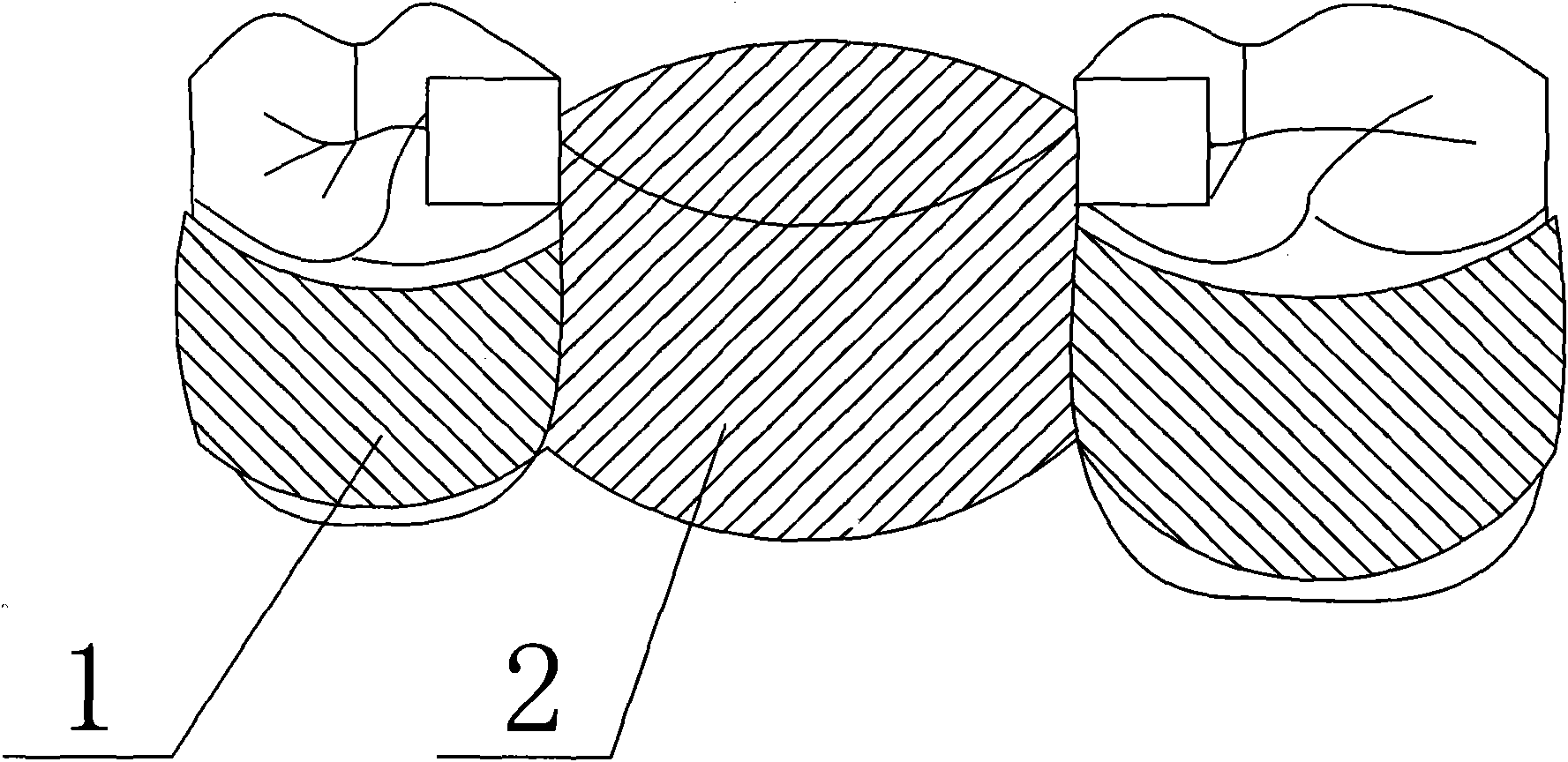

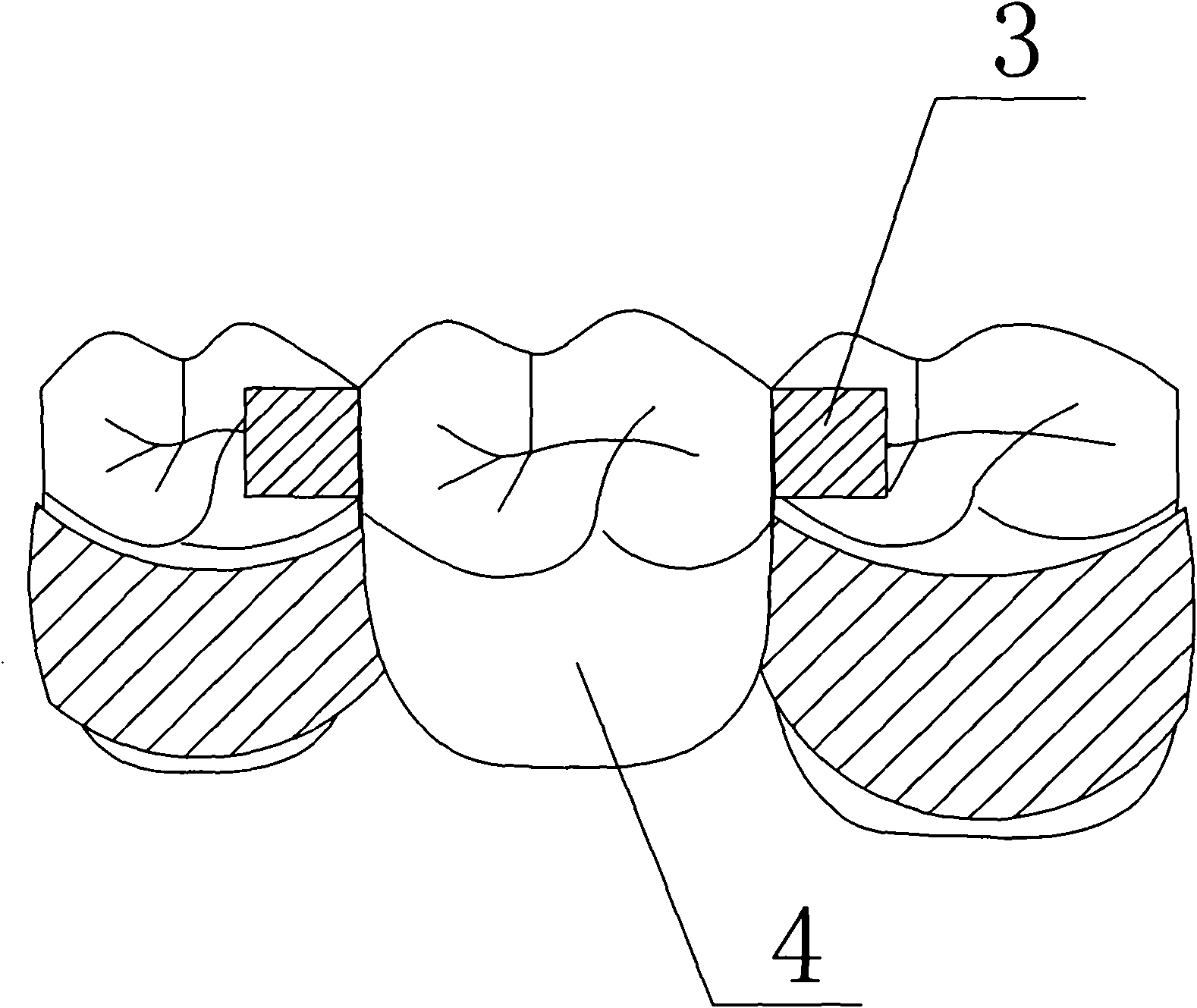

[0017] Such as Figure 1-2 As shown, a method for using a constrained bonding bridge type denture, it includes the following steps:

[0018] 1. Tooth preparation on the lingual-palatal side and the adjacent wing plate area: at 0.3mm above the palatal cervical margin and 0.3mm at the jaw margin, use a spherical diamond bur to grind the gingival margin and the jaw margin to a depth of 0.5mm respectively groove, use a wheel-shaped diamond bur to evenly remove the tooth tissue between the indicated grooves;

[0019] 2. Preparation of the inlay rest socket: prepare an inlay hole with a depth of 1.5mm at the position of the maxillofacial rest, and abduct the axial wall by 15°;

[0020] Three, the production of working mold: take mold; Described take mold adopts conventional method;

[0021] 4. Manufacture of the tongue device: In order to improve the precision, the phosphate model was made with agar by using the belt mold casting method; the tongue device includes the lingual and ...

Embodiment 2

[0026] Such as Figure 1-2 As shown, a method for using a constrained bonding bridge type denture, it includes the following steps:

[0027] 1. Tooth preparation on the lingual-palatal side and adjacent wing plate area: at 0.5mm above the palatal cervical margin and 0.5mm at the maxillary margin, use a spherical emery bur to grind the gingival margin and the maxillary margin to a depth of 0.7mm respectively groove, use a wheel-shaped diamond bur to evenly remove the tooth tissue between the indicated grooves;

[0028] 2. Preparation of the inlay rest socket: prepare an inlay hole with a depth of 1.2mm at the position of the maxillofacial rest, and abduct the axial wall by 15°;

[0029] Three, the production of working mold: take mold; Described take mold adopts conventional method;

[0030] 4. Manufacture of the tongue device: In order to improve the precision, the phosphate model was made with agar by using the belt mold casting method; the tongue device includes the lingua...

Embodiment 3

[0035] Such as Figure 1-2 As shown, a method for using a constrained bonding bridge type denture, it includes the following steps:

[0036] 1. Tooth preparation on the lingual-palatal side and the adjacent wing plate area: at 0.7mm above the palatal cervical margin and 0.7mm at the jaw margin, use a spherical emery bur to grind the gingival margin and the jaw margin to a depth of 0.8mm respectively groove, use a wheel-shaped diamond bur to evenly remove the tooth tissue between the indicated grooves;

[0037] 2. Preparation of the inlay rest socket: prepare an inlay hole with a depth of 1 mm at the position of the maxillofacial rest, and abduct the axial wall by 15°;

[0038] Three, the production of working mold: take mold; Described take mold adopts conventional method;

[0039] 4. Manufacture of the tongue device: In order to improve the precision, the phosphate model was made with agar by using the belt mold casting method; the tongue device includes the lingual and pal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com