Rotary alternate pill collecting mechanism of pill dropping machine and pill dropping machine thereof

A dripping pill machine and rotating shaft technology, applied in the field of dripping pill machine manufacturing, can solve the problems of complex structure of the collection mechanism, cumbersome operation, time-consuming and laborious, etc., and achieve the effect of easy cleaning, rapid collection and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

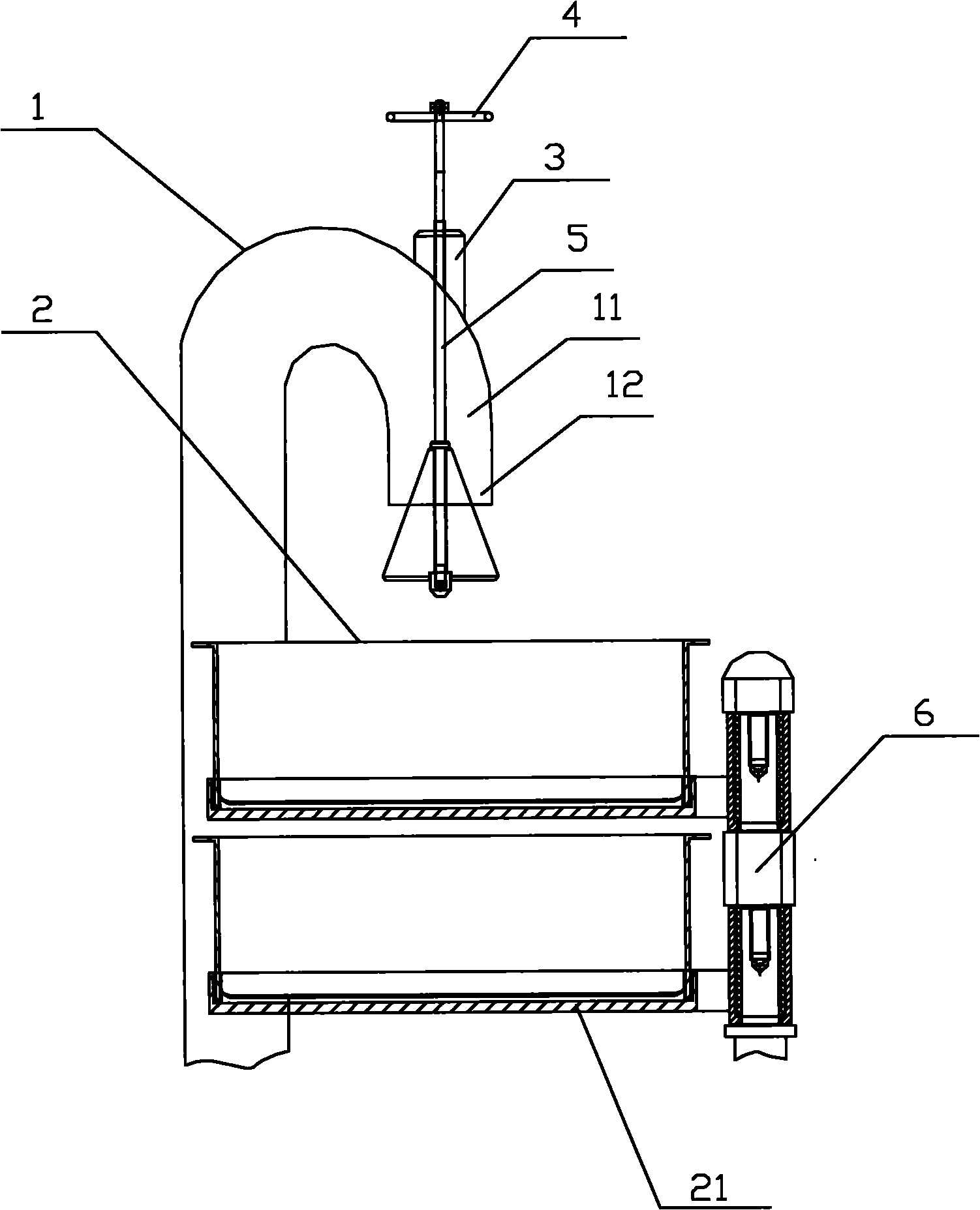

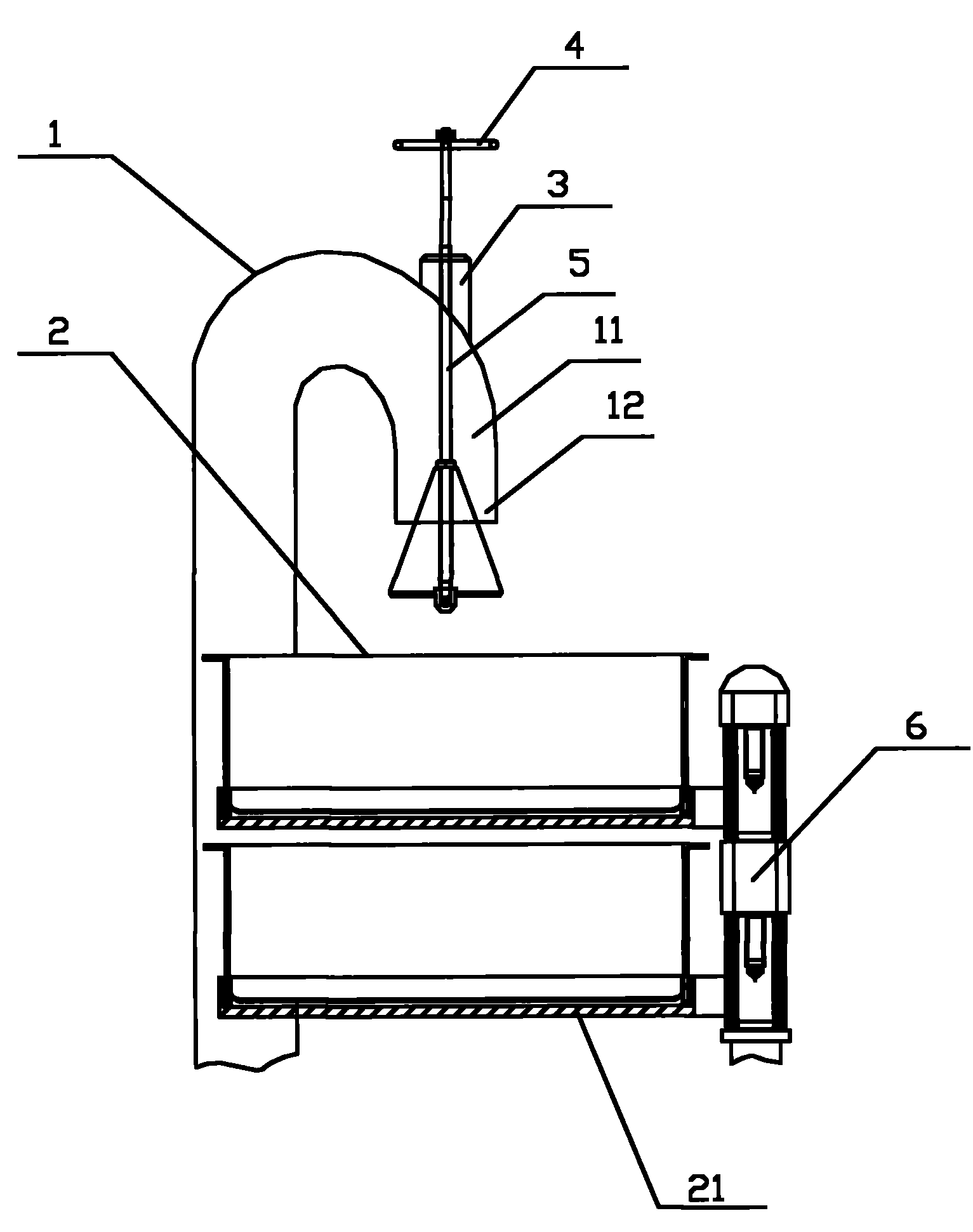

[0014] figure 1 It is a structural schematic diagram of the rotating alternate pill collecting mechanism of the dropping pill machine of the present invention. Such as figure 1 As shown, the present invention provides a rotating and alternate pill collection mechanism of a dripping pill machine, which includes an oil outlet pipe 1 and a screen basket 2 arranged below the mouth 11 of the oil outlet pipe 1 . The sieve basket 2 is multi-layered, and can be mounted on a supporting frame 21 . One end of the supporting frame 21 is fixed on the rotating shaft 6 and rotates around the rotating shaft 6 . In order to facilitate loading and unloading, the support frame 21 is provided with positioning grooves (not shown in the figure), and the sides of the screen basket 2 are inserted or lifted from the positioning grooves in the vertical direction, so that the screen basket 2 can be mounted on the supporting frame. Rack 21.

[0015] In order to effectively control the flow of the mixt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com