Coating unit and pattern correcting device equipped therewith

A coating and patterning technology, which is applied to devices, coatings, and electrical components that coat liquid on the surface, can solve problems such as adverse effects on ejection stability, and achieve the effect of a simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

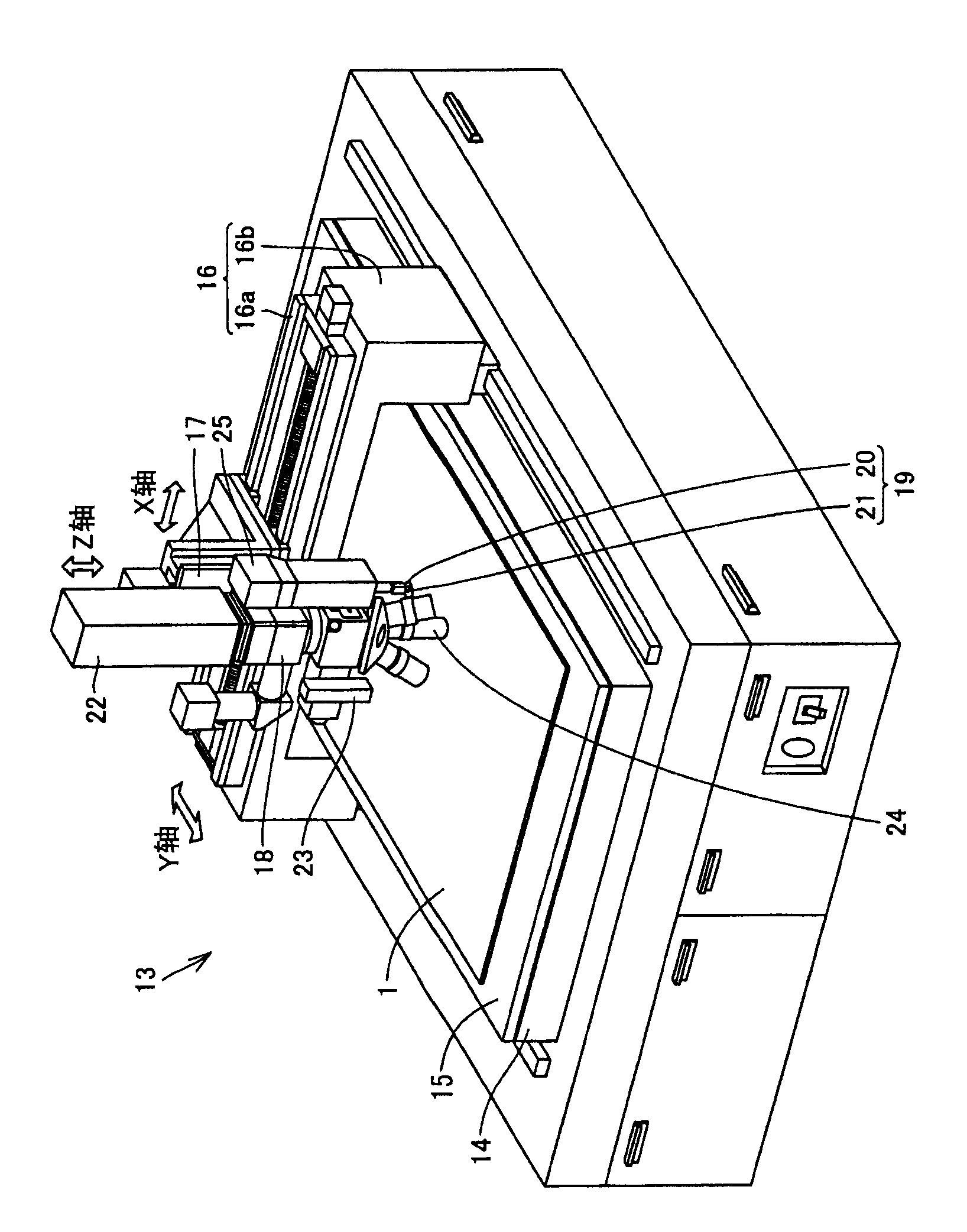

[0157] First, correction objects of the pattern correction device including the coating unit of the present application will be described. Here, although the TFT array substrate of the liquid crystal panel as the correction target is described, the correction target is not limited thereto.

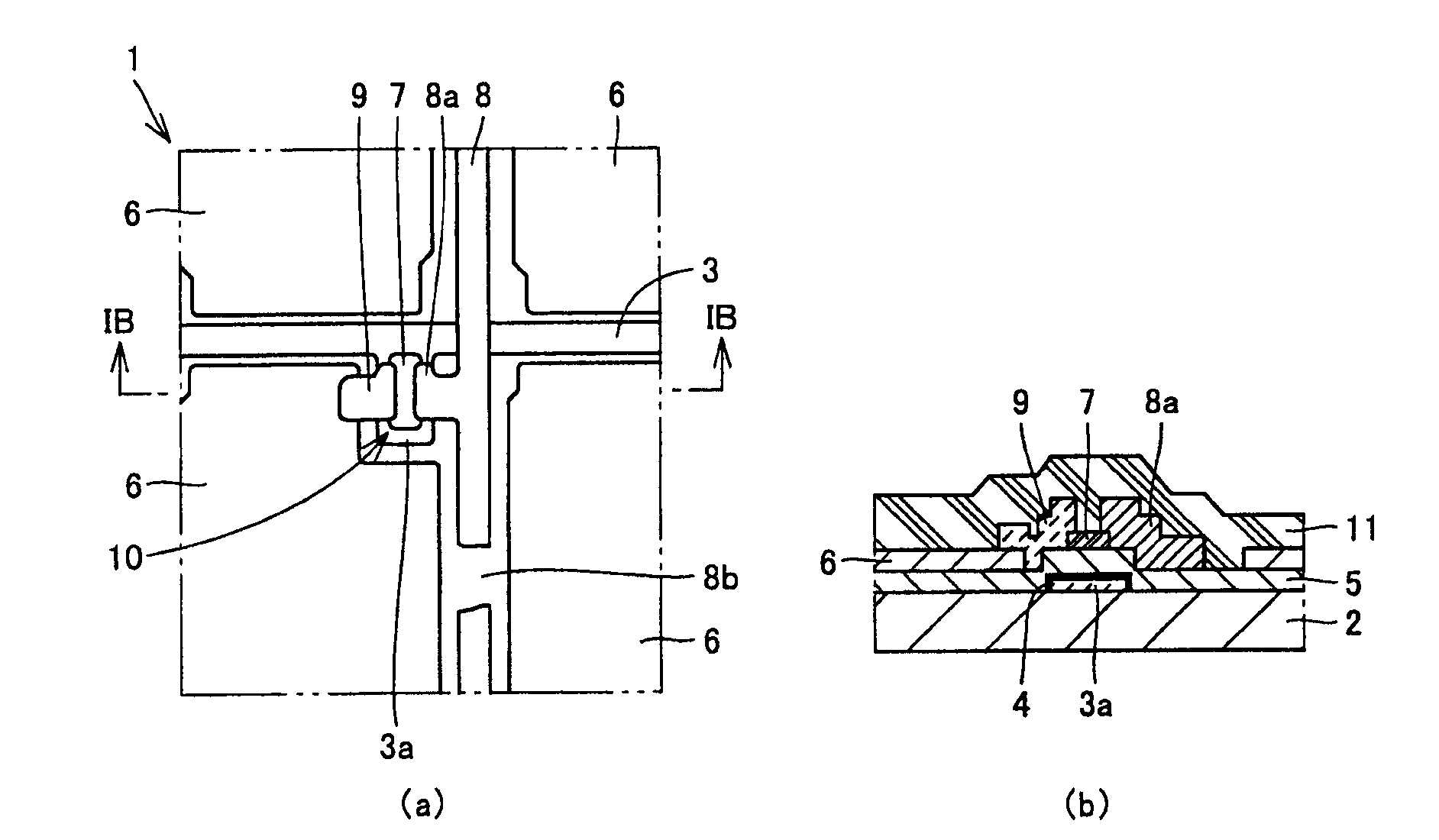

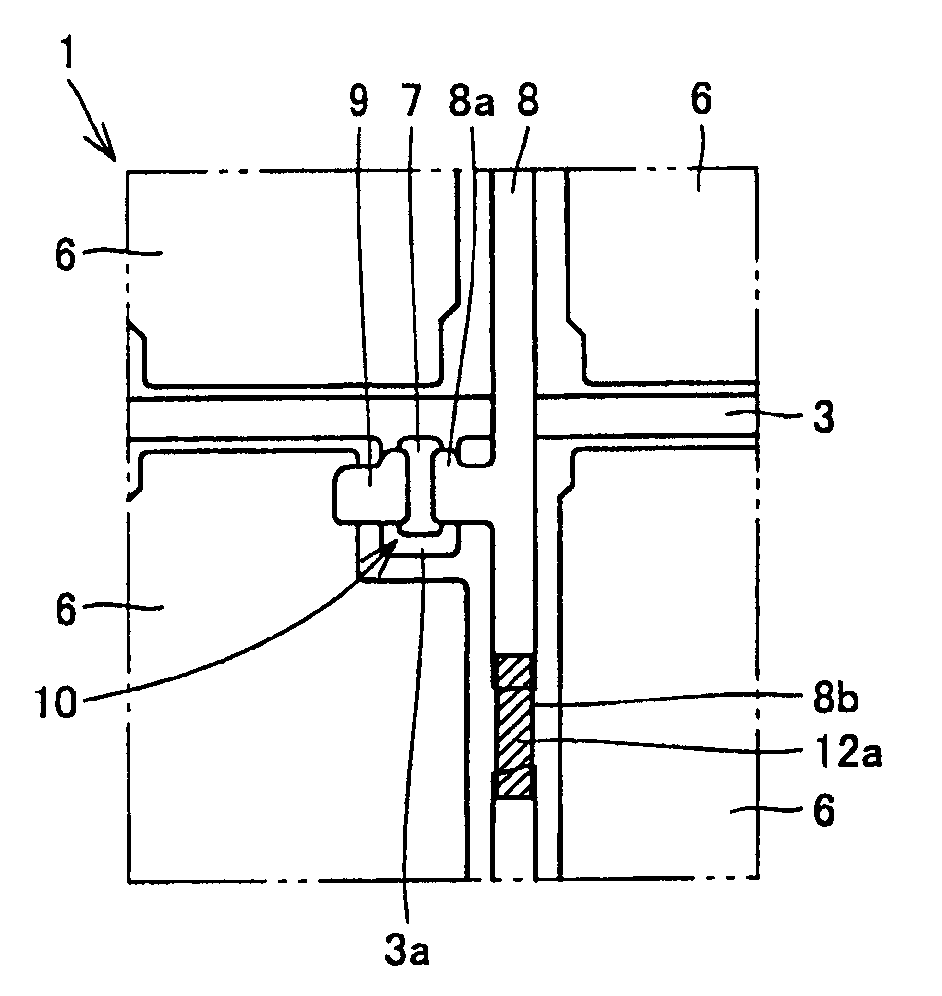

[0158] figure 1 (a) is a top view showing the main part of the TFT array substrate 1 to be corrected, figure 1 (b) is figure 1 (a) IB-IB line sectional view. exist figure 1 (a), figure 1 In (b), the TFT array substrate 1 includes a glass substrate 2 . On the surface of the glass substrate 2 are formed gate lines 3 extending in the horizontal direction in the figure, and gate electrodes 3 a protruding downward in the figure are formed at predetermined positions of the gate lines 3 . The surfaces of the gate line 3 and the gate electrode 3 a are covered with a gate insulating film 4 , and the surfaces of the gate insulating film 4 and the glass substrate 2 are covered with a gate insul...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com