Improved structure of forging machine tool C-shaped body

A technology for forging machine tools and fuselages, which is applied in the field of C-shaped fuselage structures, can solve problems such as increased manufacturing costs, uneven front and rear gaps, and failure to apply, so as to improve performance and productivity, increase technical gold content, and expand market share. rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

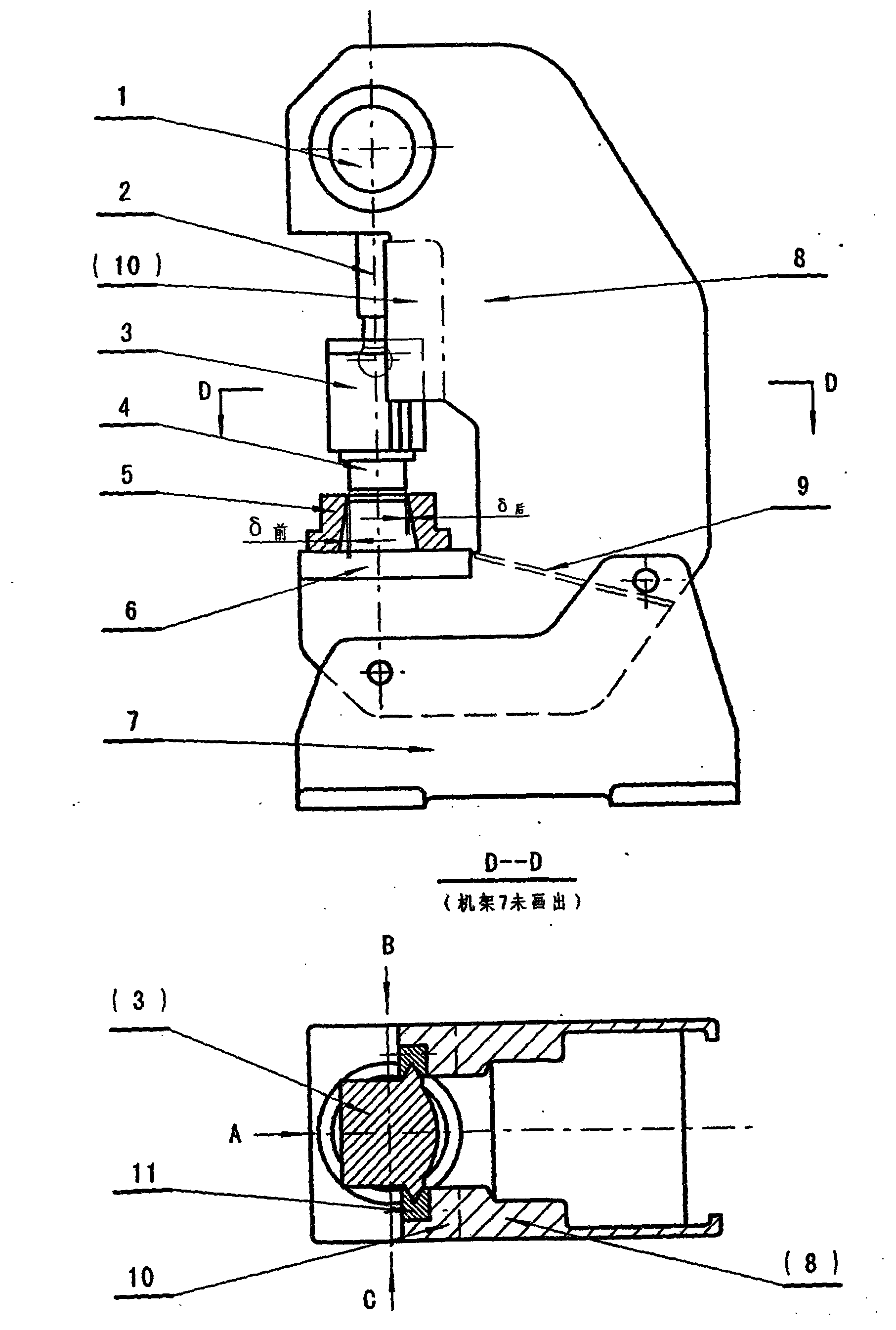

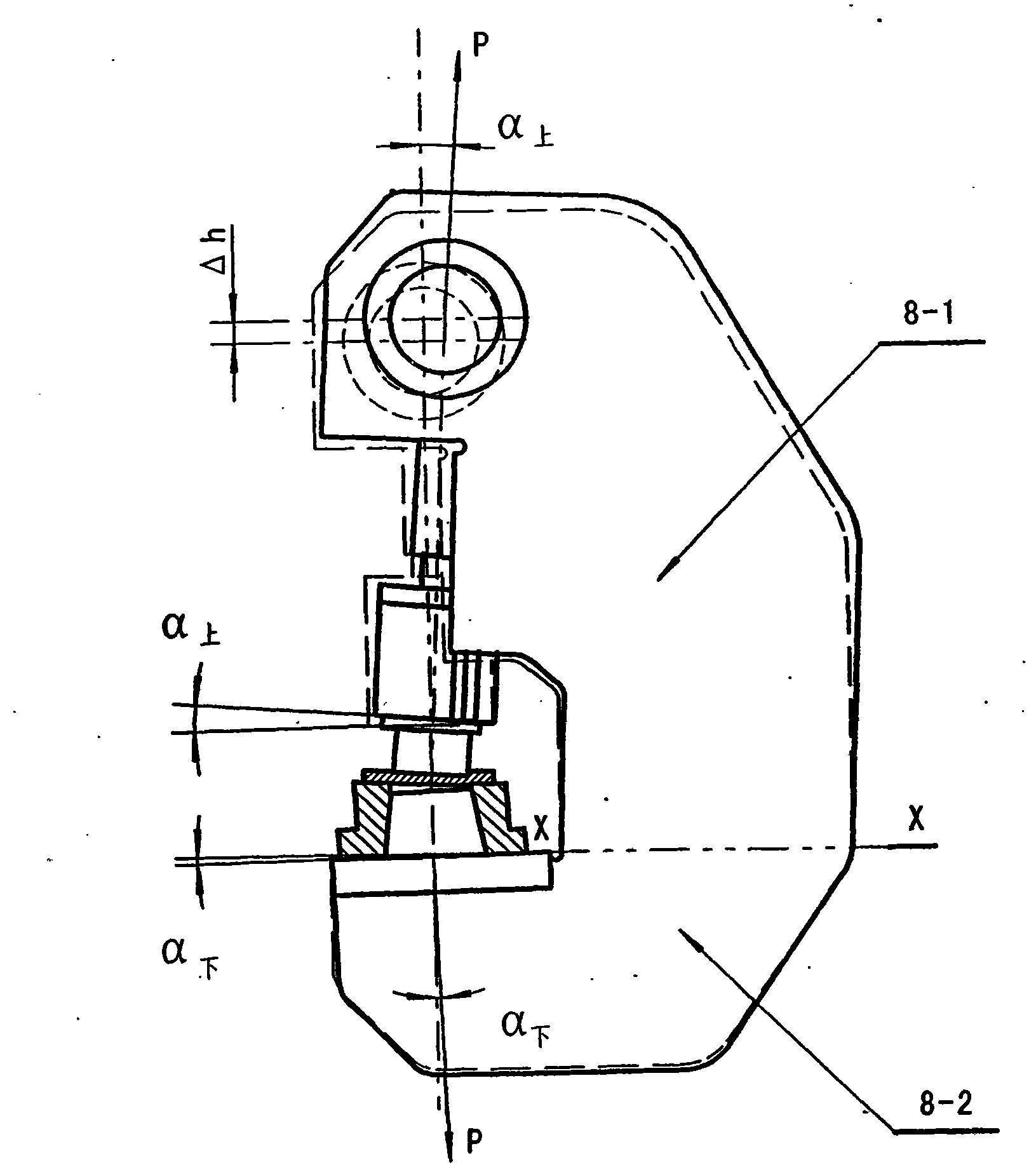

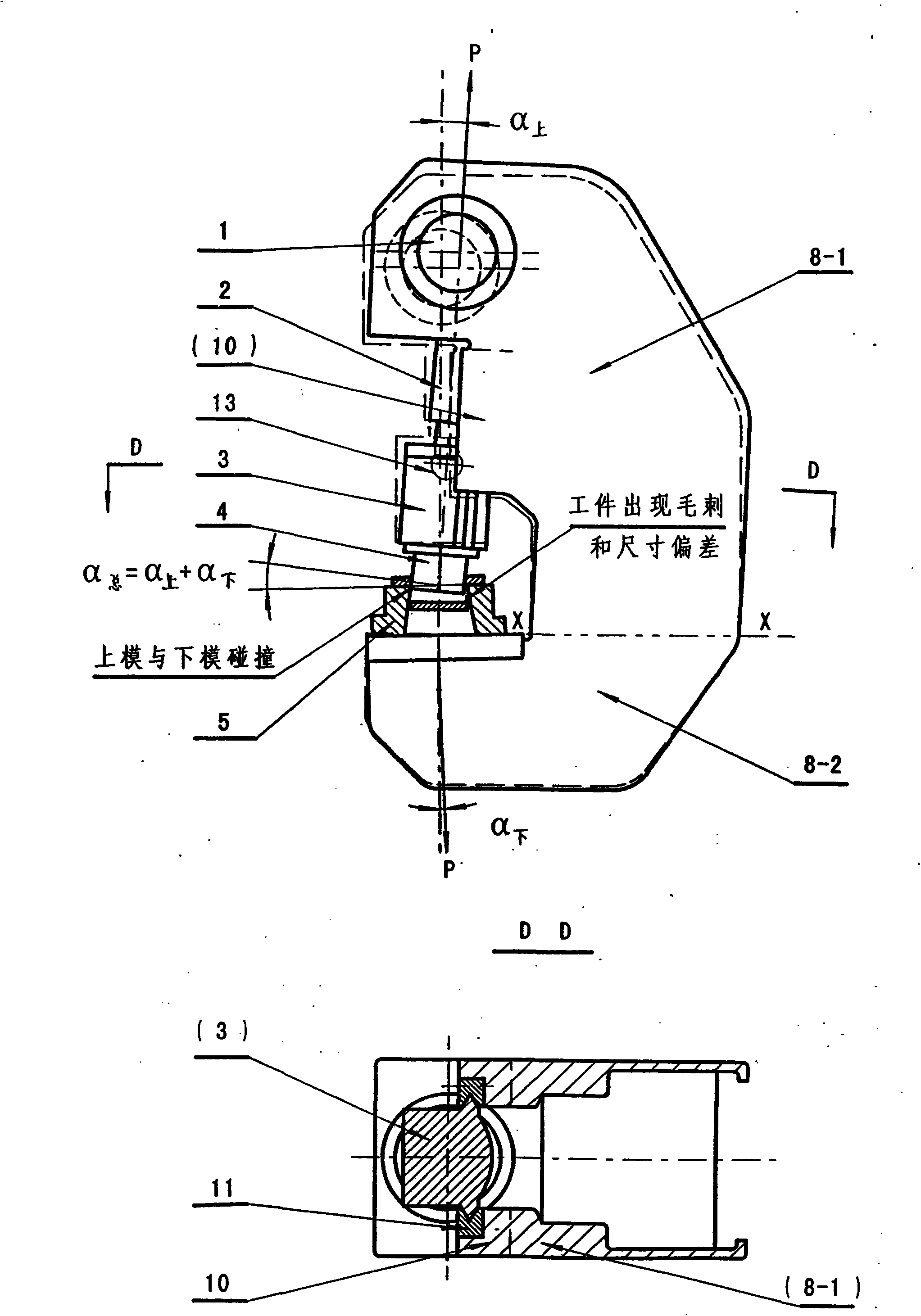

[0029] The first example Figure 4 with image 3 As shown, the part of the base [10] of the fixed rail [11] on the upper body [8-1] is separated from the upper body [8-1], and the separated base part [10] is on the upper part The outer side of the fuselage [8-1] extends backward and downward to form a support plate [12], and the support plate [12] is integrated with the side plate [14] of the lower fuselage [8-2]. In this way, when the open press is under working pressure, although the upper fuselage [8-1] will produce upward angular deformation α on , But because the base part [10] of the fixed guide rail [11] has been separated from the upper body [8-1], it will not drive the slider [3] and the upper mold [4] to undergo upward angular deformation α on ; Although the lower body [8-2] and the lower mold [5] will produce downward angular deformation α under , But at the same time it must also drive the side plate [14], support plate [12], base [10], guide rail [11] and slider [...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com