Automatic tapping machine

A technology of automatic tapping machine and tapping head, which is applied in the field of tapping machine, can solve the problems of low production efficiency and high labor intensity, and achieve the effect of reducing processing time, reducing labor intensity and improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

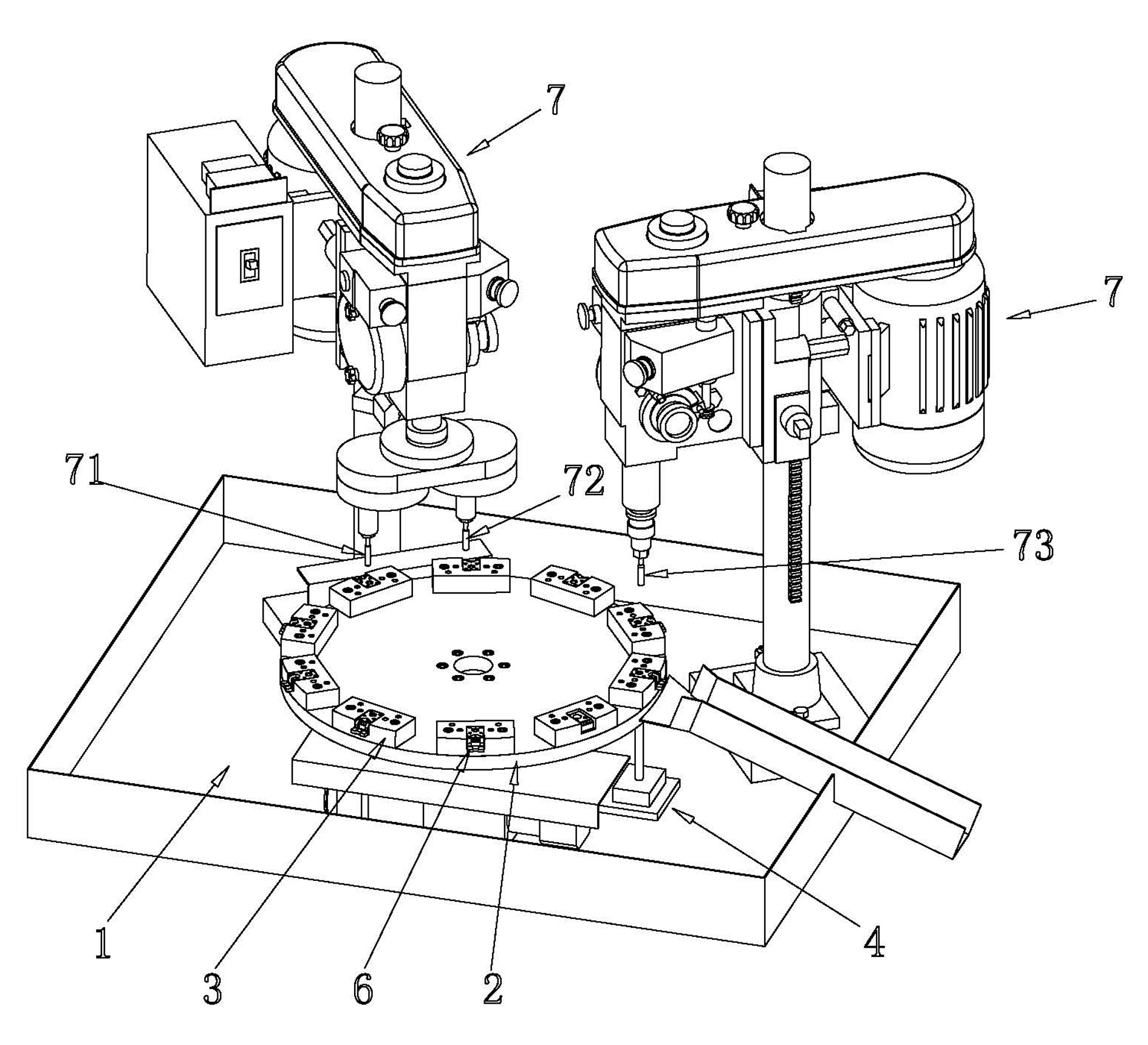

[0027] refer to figure 1 , figure 1 It is a three-dimensional schematic diagram of an embodiment of the present invention. The automatic tapping machine shown in the figure includes: a base 1, a rotating disk 2, several molds 3, two tapping mechanisms and a discharge device 4.

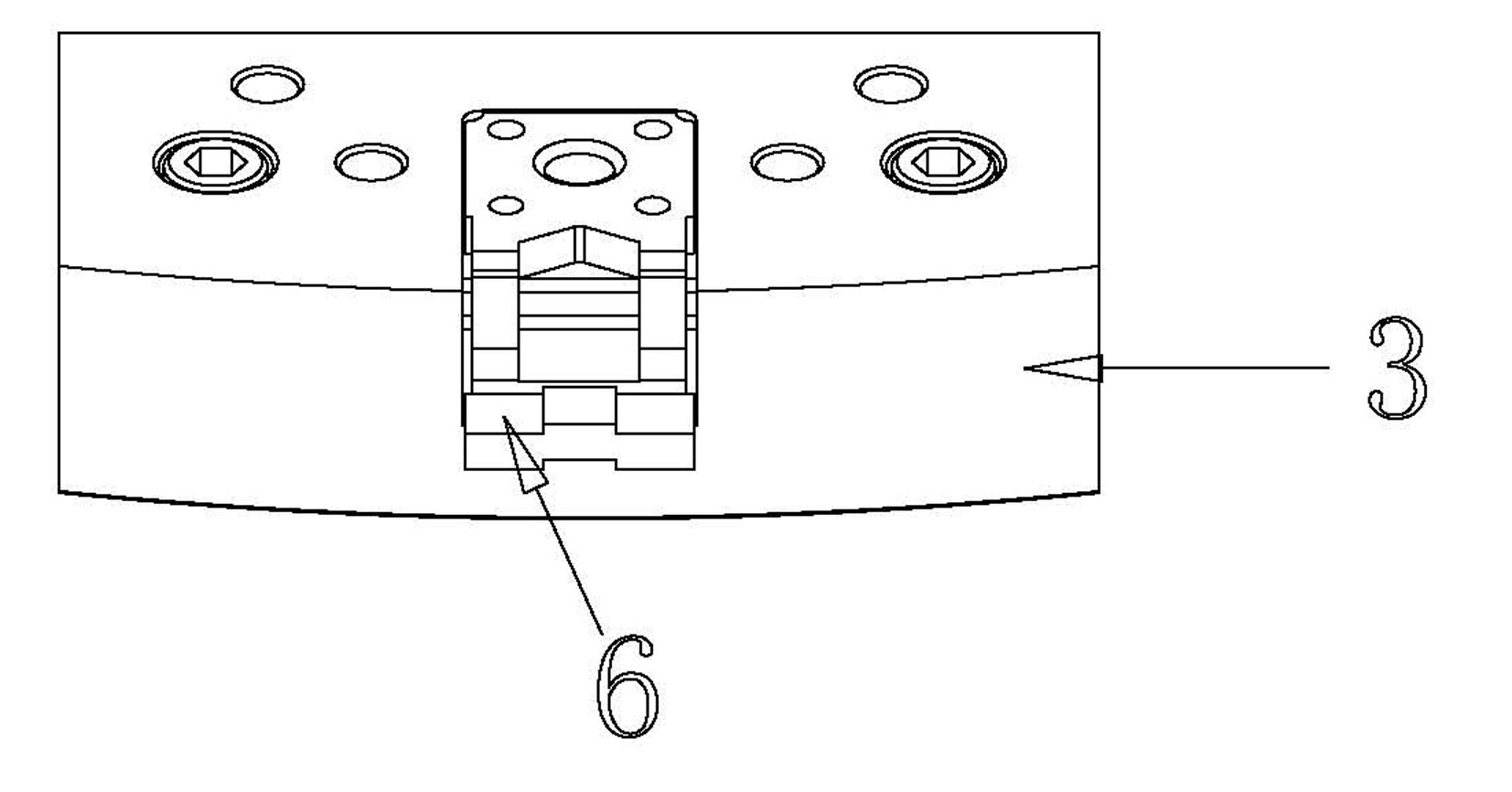

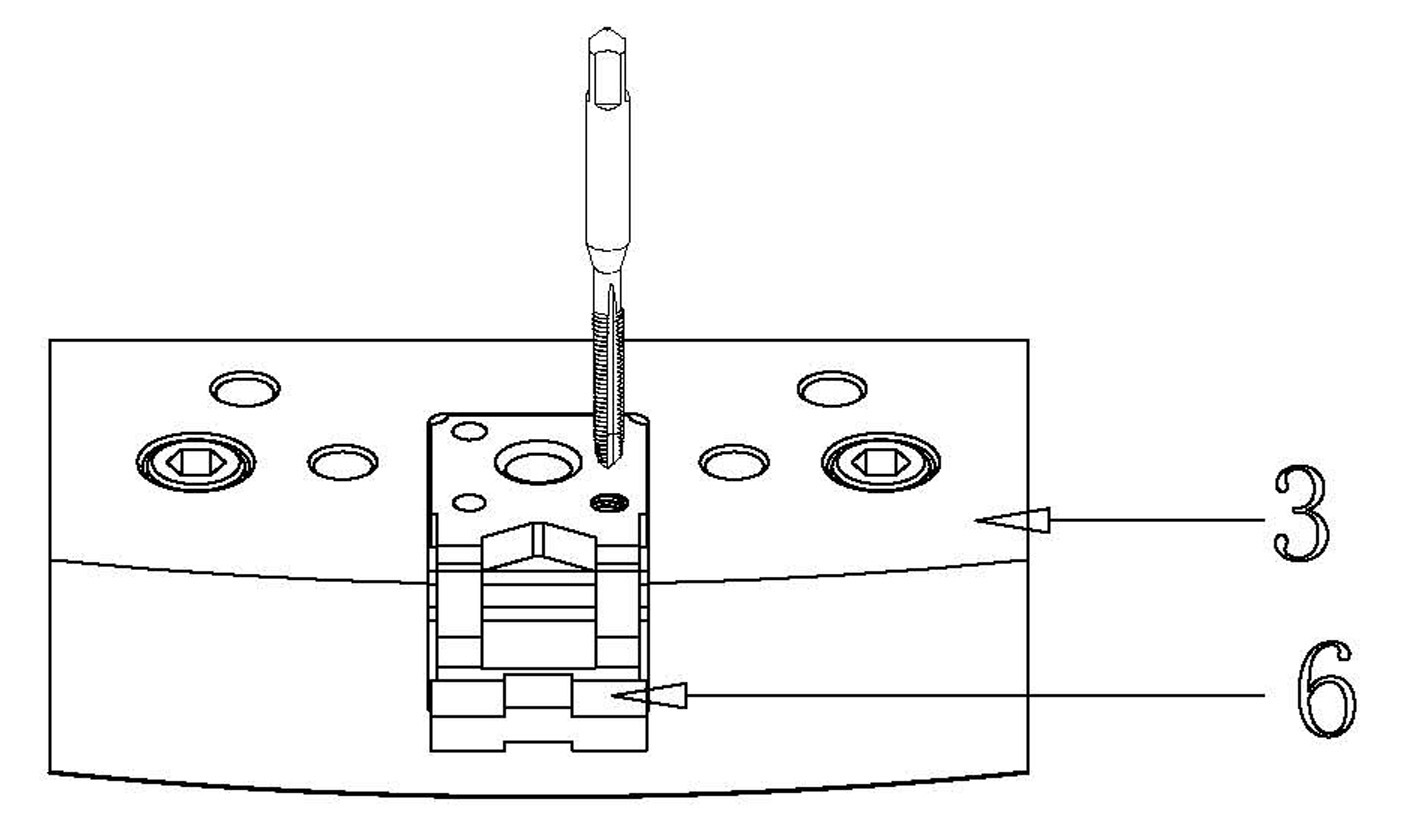

[0028] The rotating disc 2 is installed on the base by a rotating mechanism 5, such as Figure 13 , Figure 14 as shown,

[0029] In this embodiment, the rotating mechanism 5 includes a ratchet 51 and a driving cylinder 52, wherein the rotating disc 2 is fixedly connected to the ratchet 51, and the ratchet 51 can drive the rotating disc 2 to rotate synchronously when the ratchet 51 rotates. Interlocking block 53 is installed on the top, interlocking block 53 upper pivot is provided with push hook 54, and push hook 54 engages with ratchet 51, is installed on interlocking block 53 and pushes hook back-moving spring 55, and one side of ratchet 51 is installed to prevent The hook 56 that the ratchet 51...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap