Inner circular seam welding machine system and inner circular seam welding method

A welding machine and inner circumferential seam technology, applied in welding equipment, welding equipment, auxiliary welding equipment, etc., can solve the problems of cumbersome feeding and adjustment mechanism, poor positioning consistency, and long time consumption, and achieve convenient simultaneous welding, Fast and accurate feeding and positioning, simple feeding and adjustment mechanism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The inner girth seam welding machine system and welding method according to the embodiments of the present invention will be described in detail below with reference to the accompanying drawings. Like reference numbers refer to like elements throughout the figures. In addition, "vertical direction or orientation" herein refers to a direction or orientation perpendicular to the ground. Herein "front-back direction or orientation" refers to front and back of the main viewing direction.

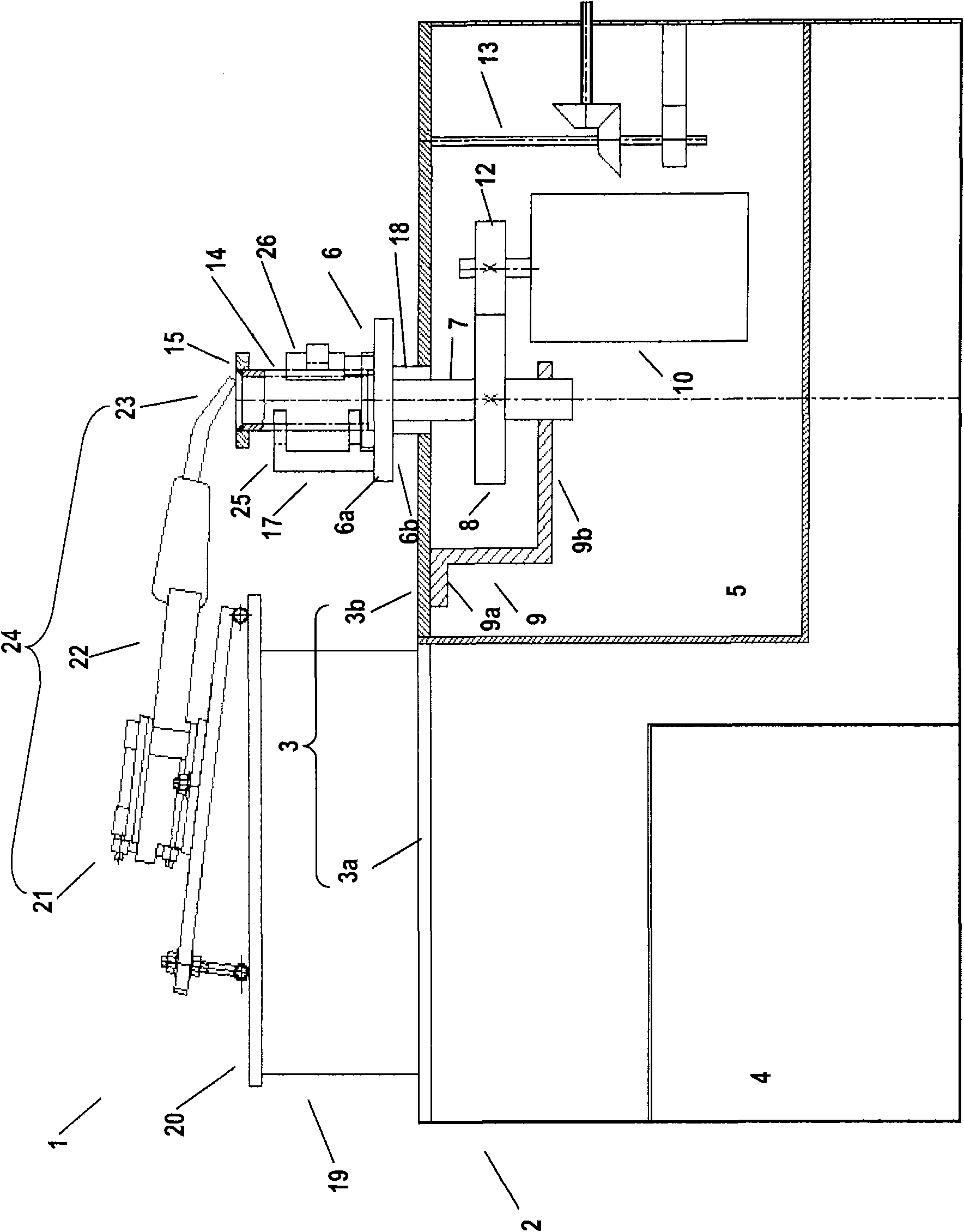

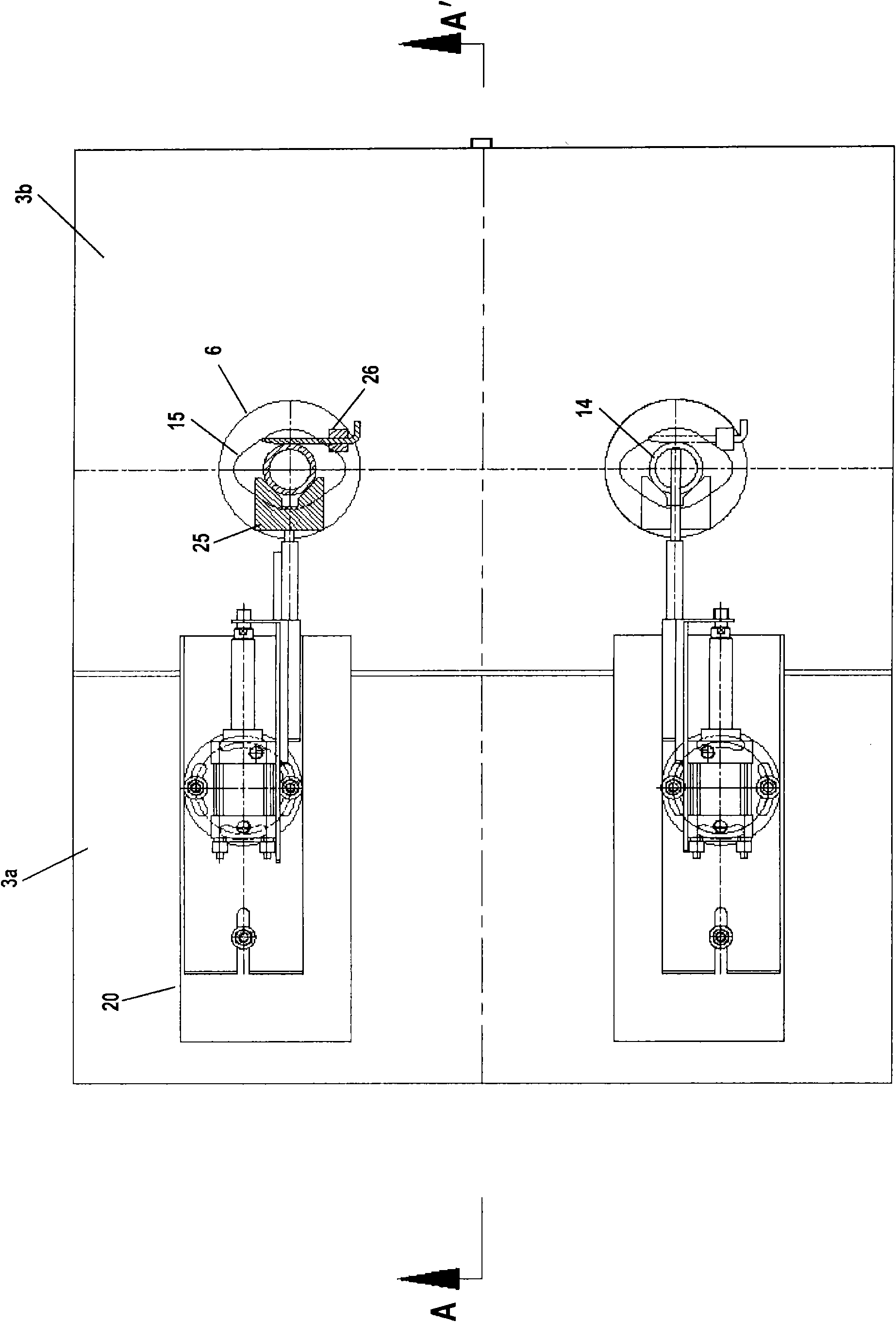

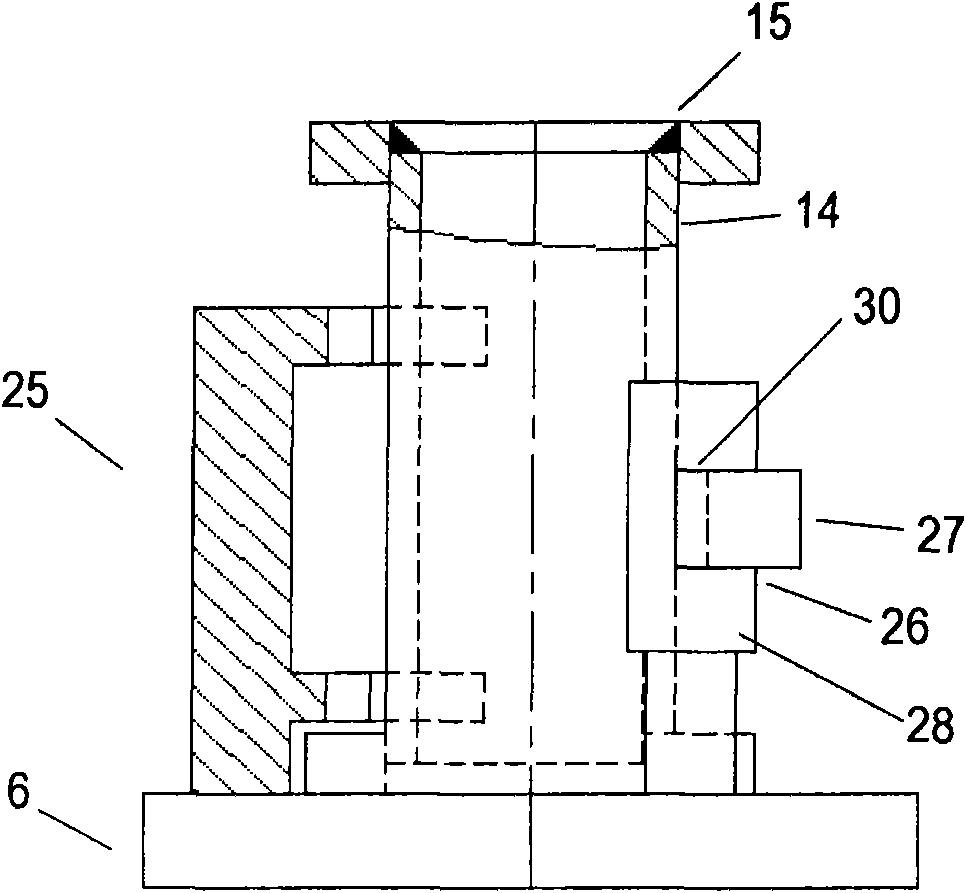

[0045] Figure 1a and Figure 1b Shows a front sectional view and a top view of an inner girth welding machine system according to an embodiment of the present invention, wherein Figure 1b Shown in the top view is the inner girth welding machine system with double stations, while Figure 1a The double-station inner girth welding machine system is shown in Figure 1bThe front section view taken by the line of symmetry A-A' in . It should be understood that the figures are schematic on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com