Plate spring tensioning tool and machining method

A leaf spring and tooling technology, which is applied in the field of leaf spring tensioning tooling and leaf spring processing, can solve problems that affect the function and life of the vibration device, cannot meet the tensioning requirements, and the negative tolerance of the hole distance of the leaf spring group. Consistency, avoiding errors, and ensuring the effect of true negative tolerances

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

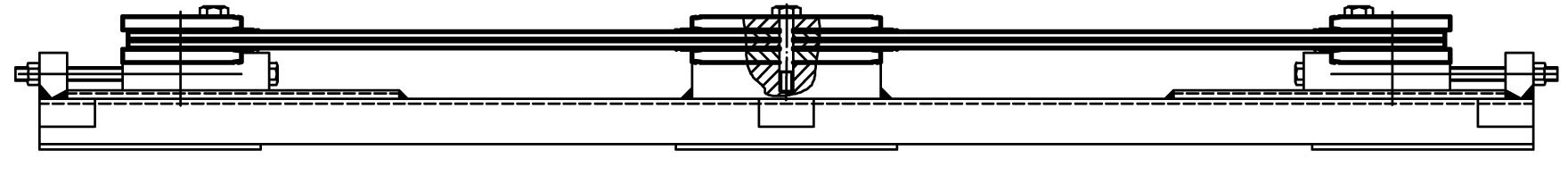

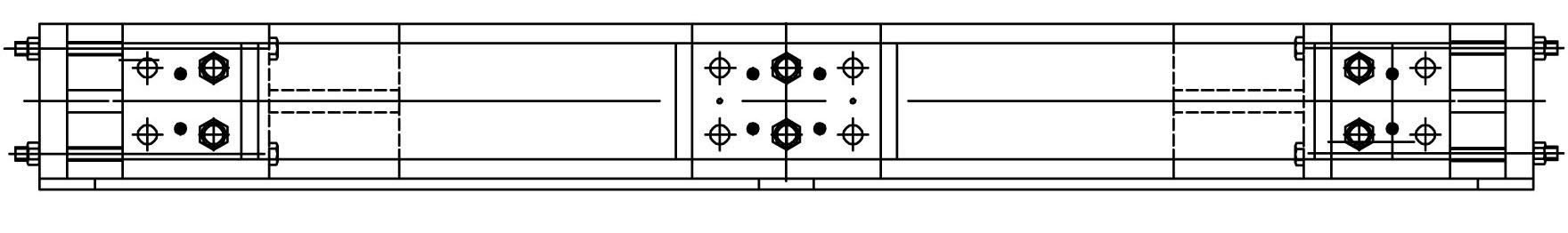

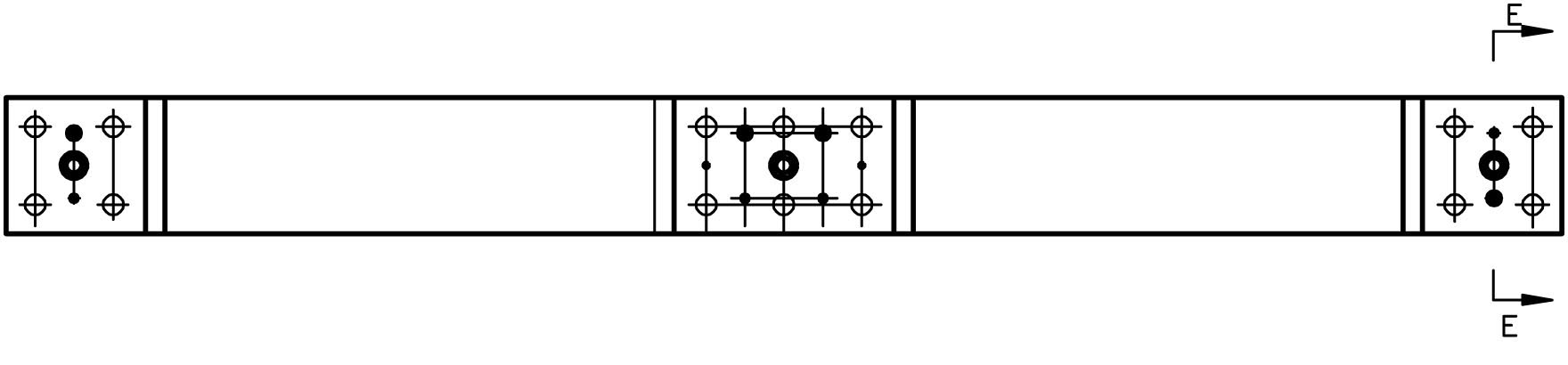

[0029] like figure 1 , figure 2 Among them, a leaf spring tensioning tool, the two ends of the bottom plate 5 are connected to the movable baffle 4 through tension bolts 8, and the movable baffle 4 is provided with a boss. This boss is used for hooking one side of the pressing plate 1 below.

[0030] Both ends of the bottom plate 5 are provided with bosses, and the tension bolts 8 pass through the bosses.

[0031] The middle part of the bottom plate 5 is also provided with a boss, and the boss is provided with a pin hole for assembly.

[0032] The bottom plate 5 is also provided with key structure grooves or bosses for cooperating with the movable baffle 4 . The movable baffle 4 is also provided with key structure bosses or grooves for cooperating with the bottom plate 5 . The key structure grooves or bosses cooperate with each other to limit the movable baffle 4 to slide only along the grooves or bosses.

[0033] The bottom and at least one side of the bottom plate 5 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com