Wafer replacing device used in chemical mechanical polishing equipment

A chemical machinery and exchange device technology, applied in the direction of grinding devices, metal processing equipment, grinding machine tools, etc., can solve problems such as affecting operations, wafer exchange loading failure, wafer breakage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

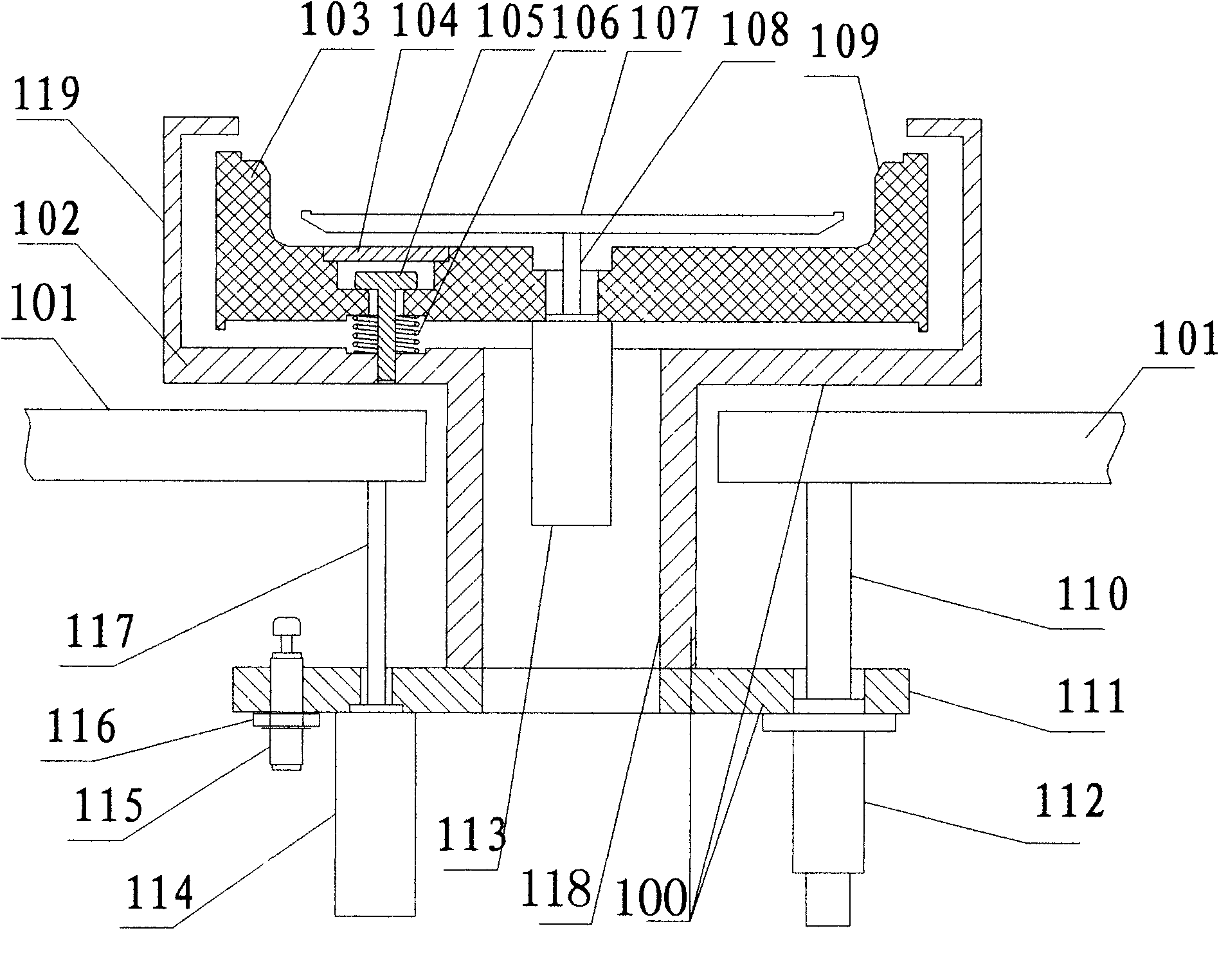

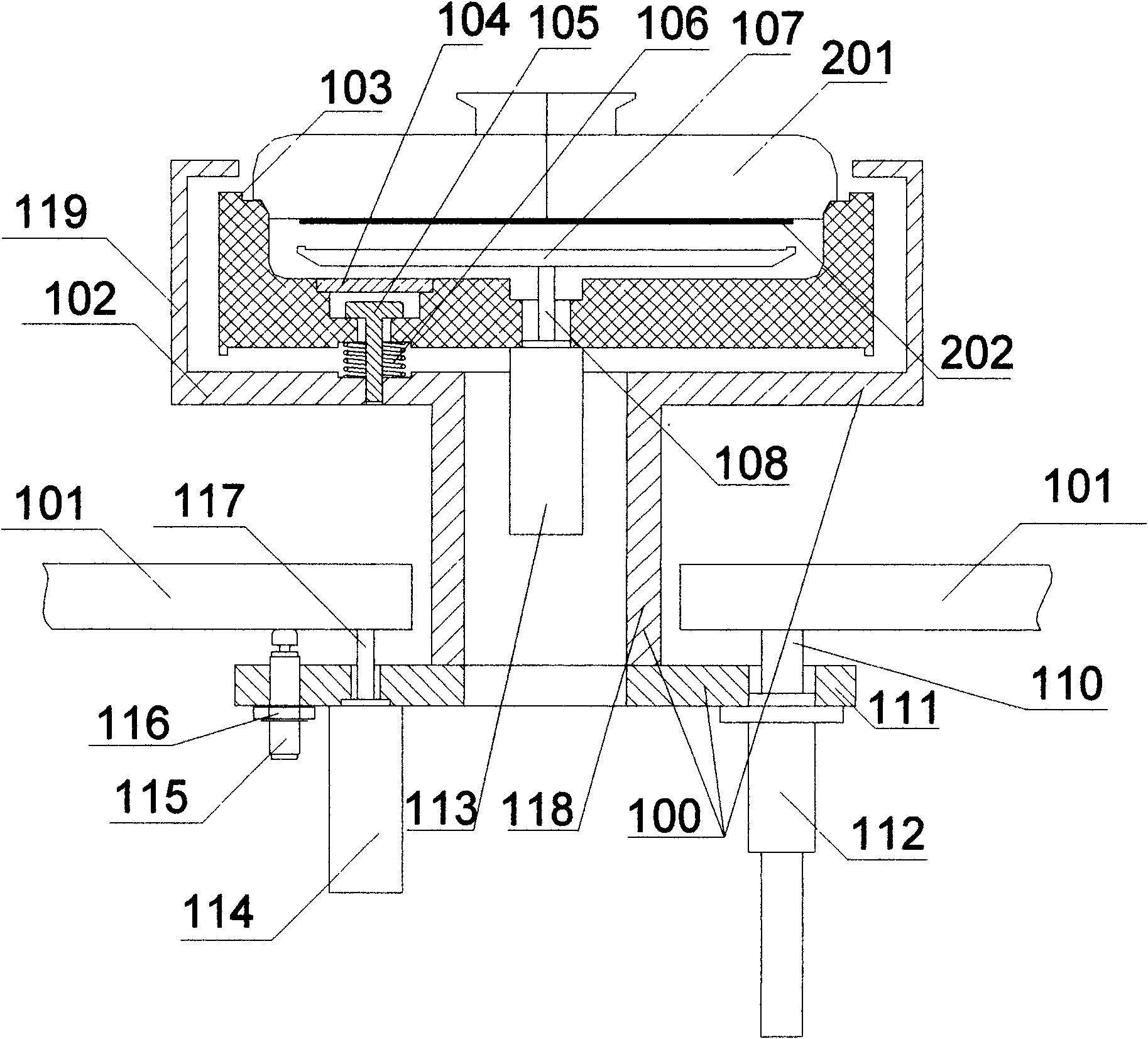

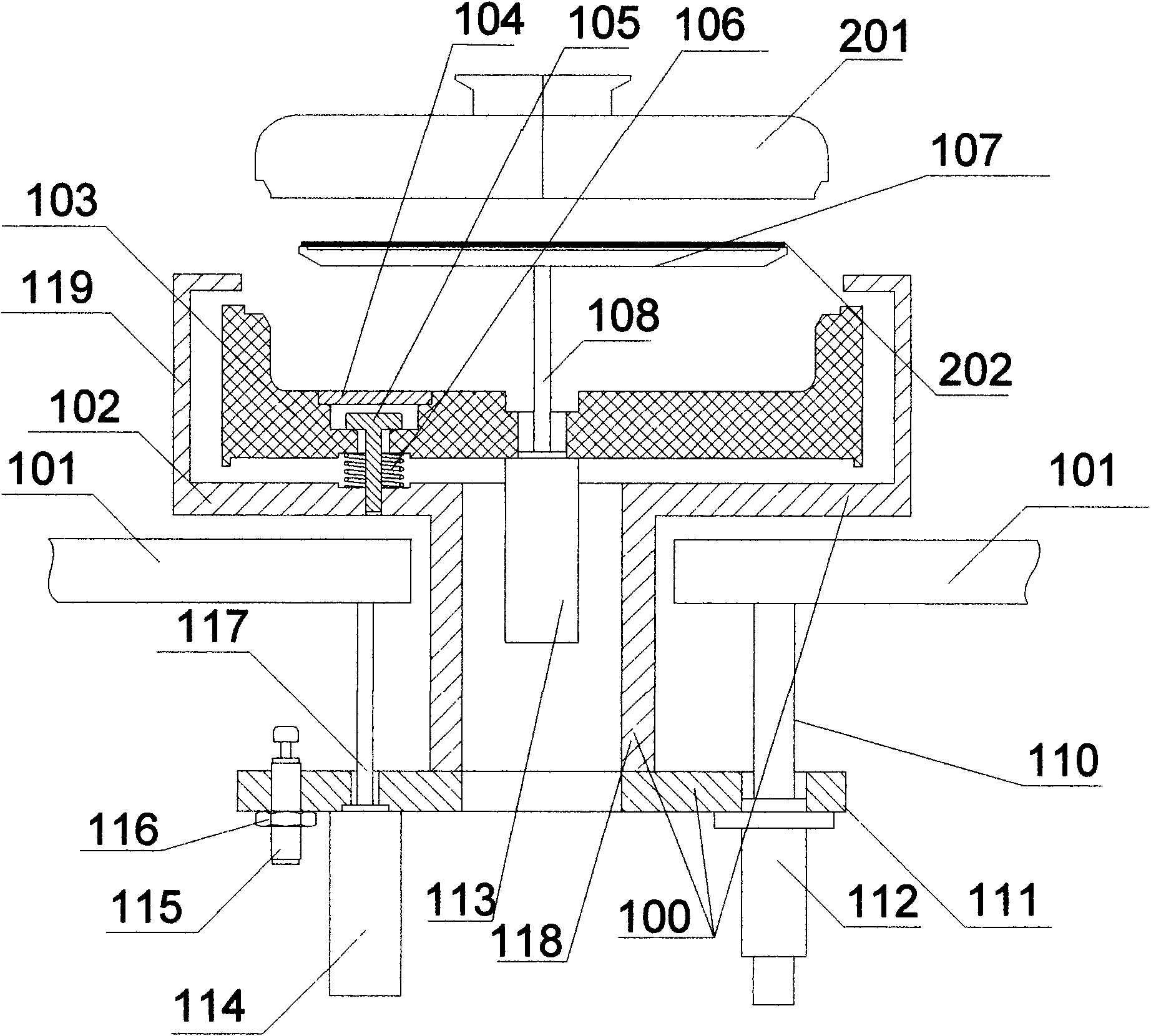

[0028] like figure 1 As shown, the present invention is a wafer exchange device for chemical mechanical polishing equipment, including a lifting frame 100, the circular basin-shaped lifting frame upper part 102 passes through the hollow cavity 118 and the circular plate-shaped lifting frame The lower part 111 is connected to form the lifting frame 100. There is a side wall 119 perpendicular to it on the upper part 102 of the lifting frame. The first cylinder 114 and the linear bearing 112 that the lifting frame 100 lifts, the guide shaft 110 passes through the linear bearing 112 and is consolidated with the base 101, and the cylinder rod 117 of the first cylinder 114 is also fixed on the machine base 101, and the lifting frame The upper part 102 is connected to the basin-shaped alignment ring 103 by the spring 106, and the second air cylinder...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com