Stepped equilibrium-atmosphere sintering process for soft-magnetic ferrite nitrogen kiln

A soft ferrite, stepped technology, applied in the field of nitrogen kiln stepped balanced atmosphere sintering process, can solve the problems of difficult to guarantee product quality, limited sintering stacking height, low sintering efficiency, etc., and reduce the scrap rate of blanks , the effect of reducing energy consumption and shortening the sintering cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] The one-stage heating treatment includes the following stages:

[0034] 1) From room temperature to 200°C, heat up at a rate of 2.6°C / min;

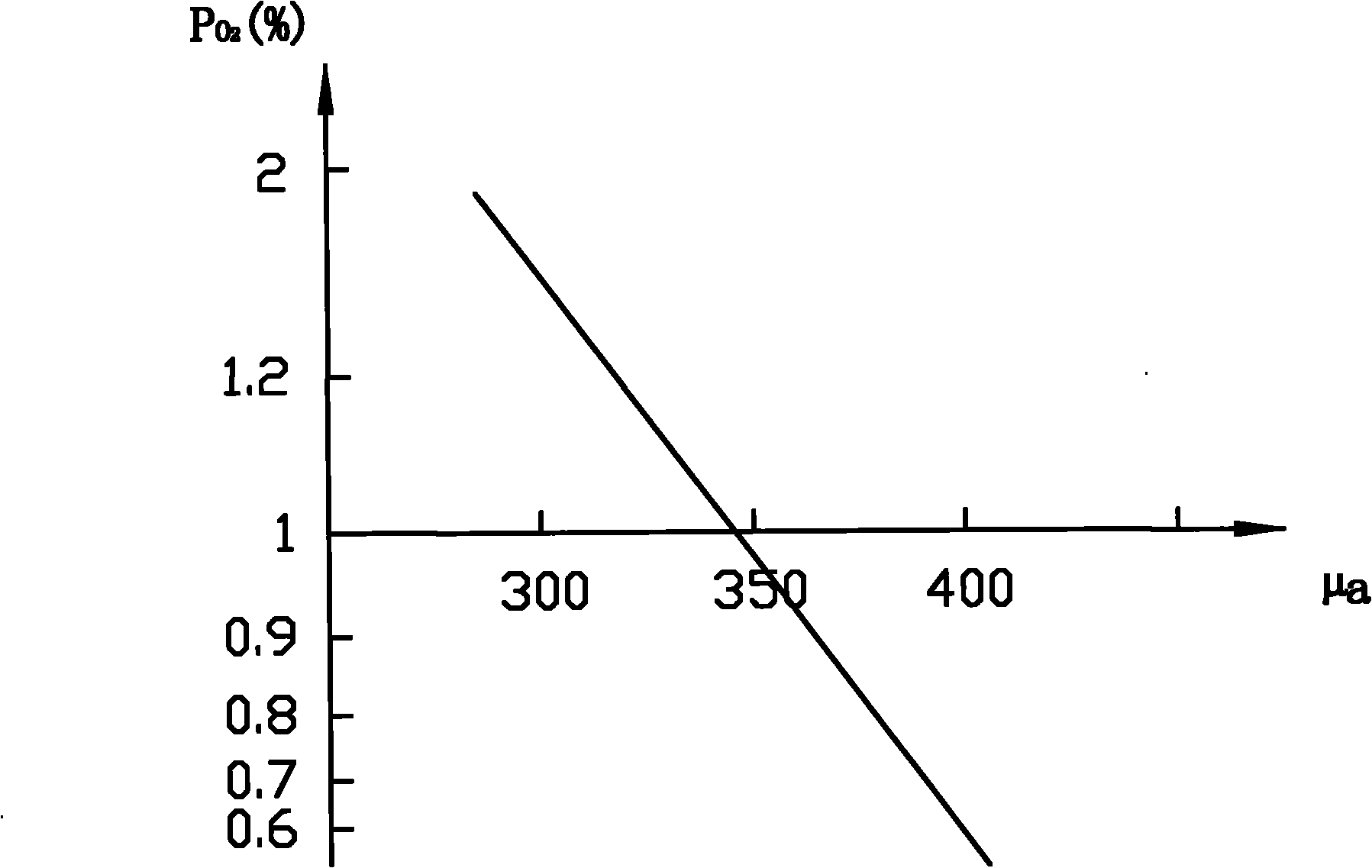

[0035] 2) From 200°C to 600°C, raise the temperature at a rate of 1.3°C / min, and continuously feed air at a rate of 480L / min when the temperature in the nitrogen kiln reaches 310°C, and then keep it warm for 5 minutes.

[0036] The two-stage heating process includes the following stages:

[0037] 1) From 600°C to 900°C, heat up at a rate of 2.75°C / min, and continuously feed air at a rate of 320L / min;

[0038] 2) From 900°C to 1250°C, heat up at a rate of 1.75°C / min, and continue to feed air at a rate of 320L / min, and then keep warm for 22 minutes.

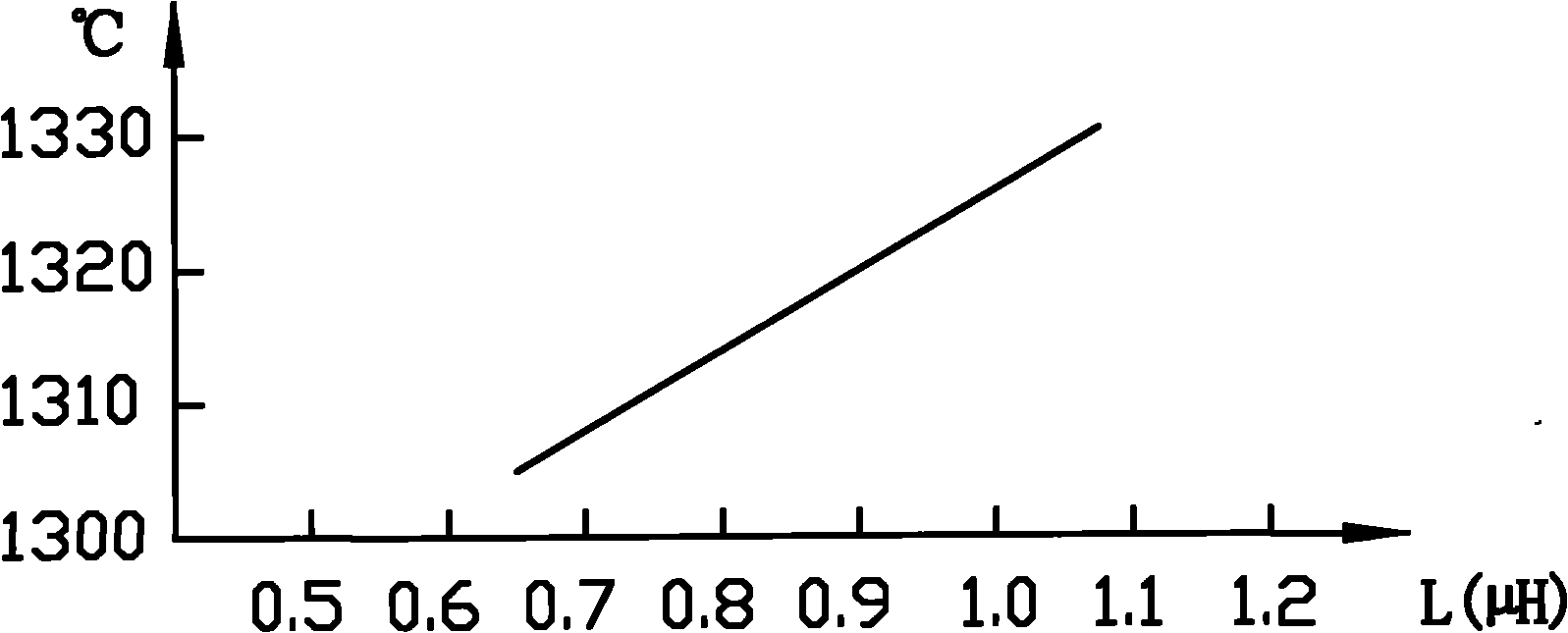

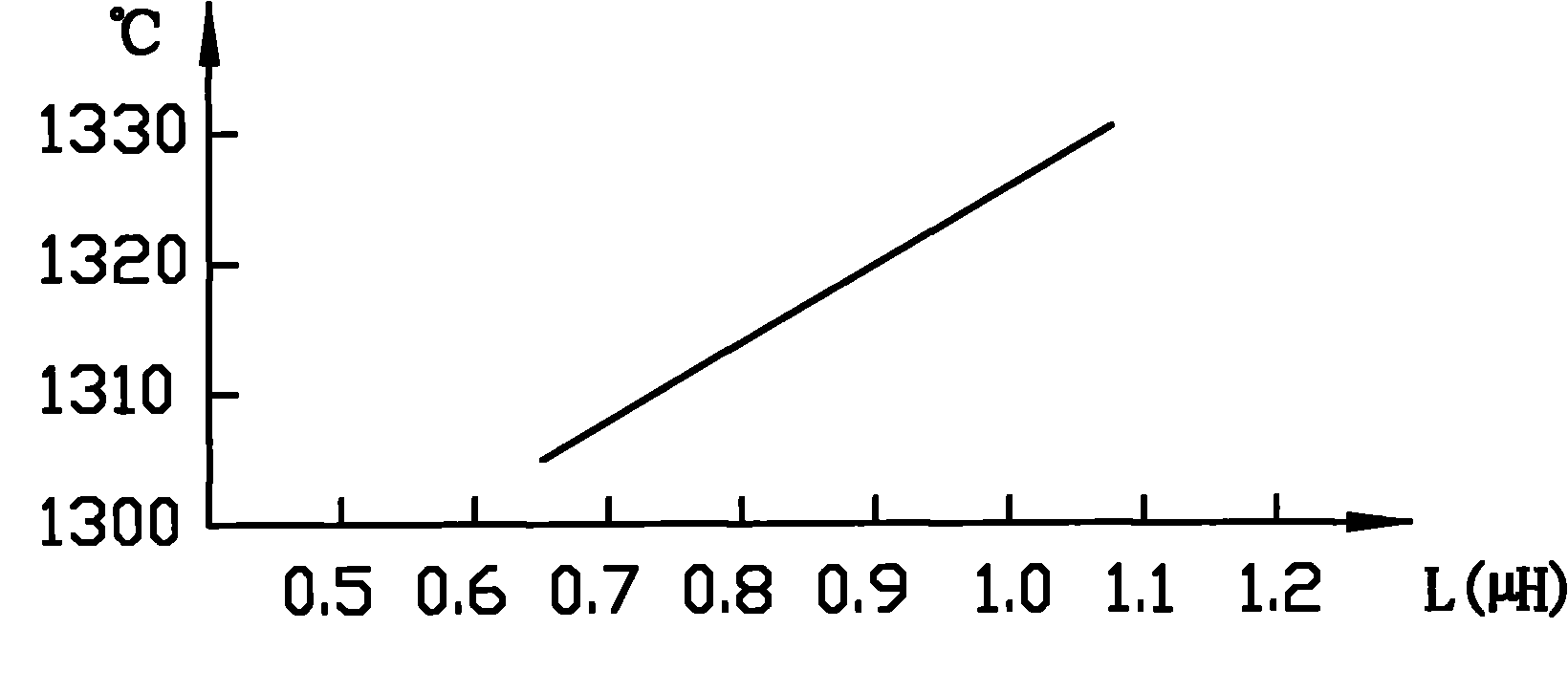

[0039] The three-stage heating process is carried out at a rate of 1.1° C. / min. After reaching 1350° C.±40° C., the holding time is 6 hours, and the oxygen partial pressure in the nitrogen kiln gradually changes from 8% to 5%.

[0040] The nitrogen kiln is cooled in stages. When the ...

Embodiment 2

[0042] The one-stage heating treatment includes the following stages:

[0043] 1) From room temperature to 200°C, heat up at a rate of 2.8°C / min;

[0044] 2) From 200°C to 600°C, heat up at a rate of 1.4°C / min, then keep warm for 5 minutes, and continuously feed air at a rate of 400L / min when the temperature in the nitrogen kiln reaches 300°C.

[0045] The two-stage heating process includes the following stages:

[0046] 1) From 600°C to 900°C, the temperature is raised at a rate of 2.6°C / min, and air is continuously fed in at a rate of 400L / min;

[0047] 2) From 900°C to 1250°C, heat up at a rate of 1.67°C / min, and continue to feed air at a rate of 400L / min, and then keep warm for 20 minutes.

[0048] In the three-stage heating process, the temperature is raised at a rate of 1.0° C. / min. After reaching 1350° C. ± 40° C., the holding time is 5 hours, and the oxygen partial pressure in the nitrogen kiln gradually changes from 8% to 5%.

[0049] The nitrogen kiln is cooled in...

Embodiment 3

[0051] The one-stage heating treatment includes the following stages:

[0052] 1) From room temperature to 200°C, heat up at a rate of 3.0°C / min;

[0053] 2) From 200°C to 600°C, raise the temperature at a rate of 1.5°C / min, and continuously feed air at a rate of 320L / min when the temperature in the nitrogen kiln reaches 285°C, and then keep it warm for 6 minutes.

[0054] The two-stage heating process includes the following stages:

[0055] 1) From 600°C to 900°C, heat up at a rate of 2.45°C / min, and continuously feed air at a rate of 480L / min;

[0056] 2) From 900°C to 1250°C, heat up at a rate of 1.60°C / min, and continue to feed air at a rate of 480L / min, and then keep warm for 18 minutes.

[0057] In the three-stage heating process, the temperature is raised at a rate of 0.9°C / min, and the heat preservation treatment time is 5 hours after reaching 1350°C±40°C, and the oxygen partial pressure in the nitrogen kiln gradually changes from 8% to 5%.

[0058] The nitrogen kiln ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com