High-wind-temperature hot blast heater with automatic air preheater

An air preheating and self-preheating technology, applied in blast furnaces, blast furnace details, blast furnace parts and other directions, can solve the problems of complex equipment, large energy consumption, insufficient combustion, etc., and achieve long service life and simple piping system. , the effect of reducing heat dissipation loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

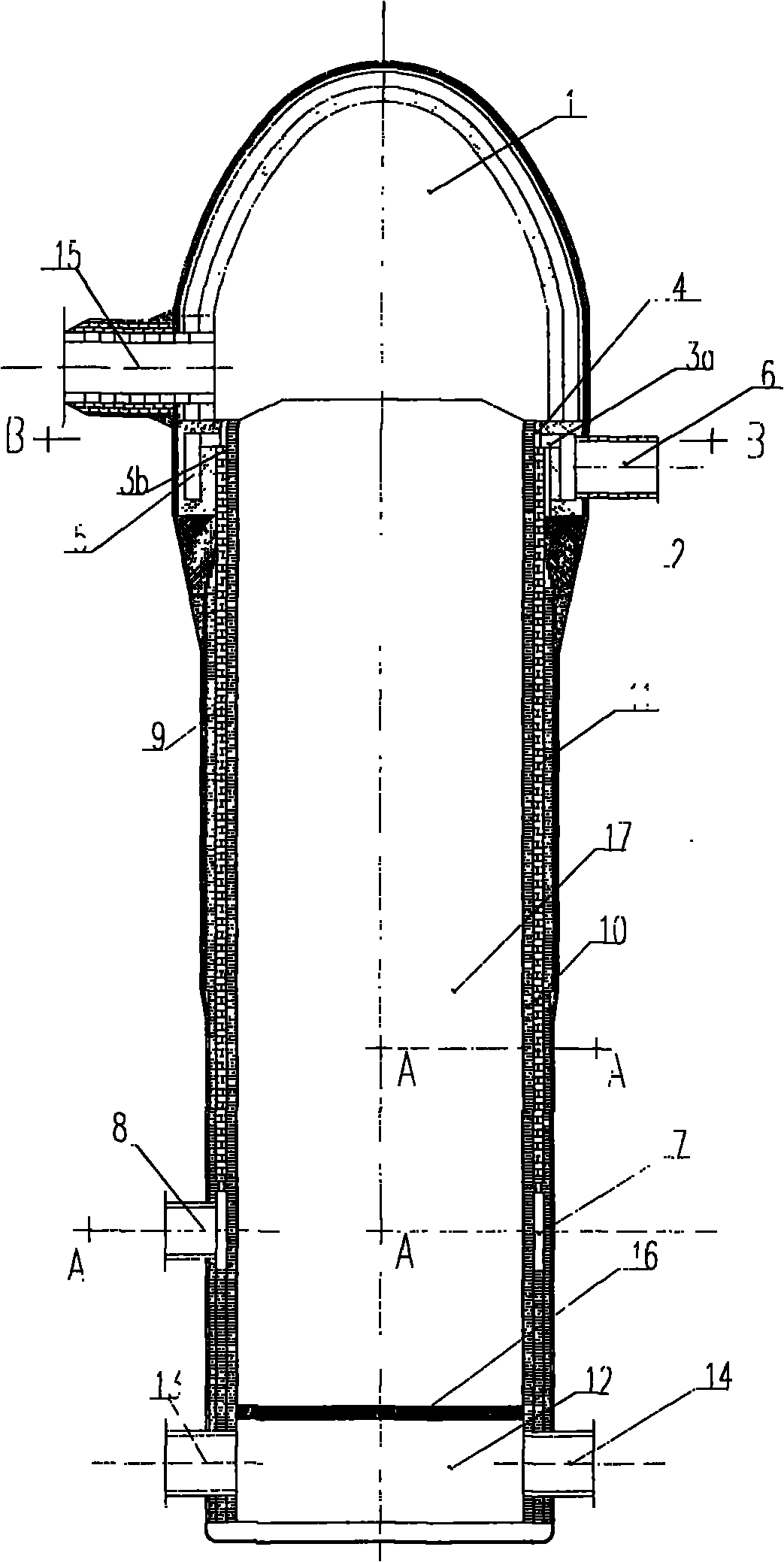

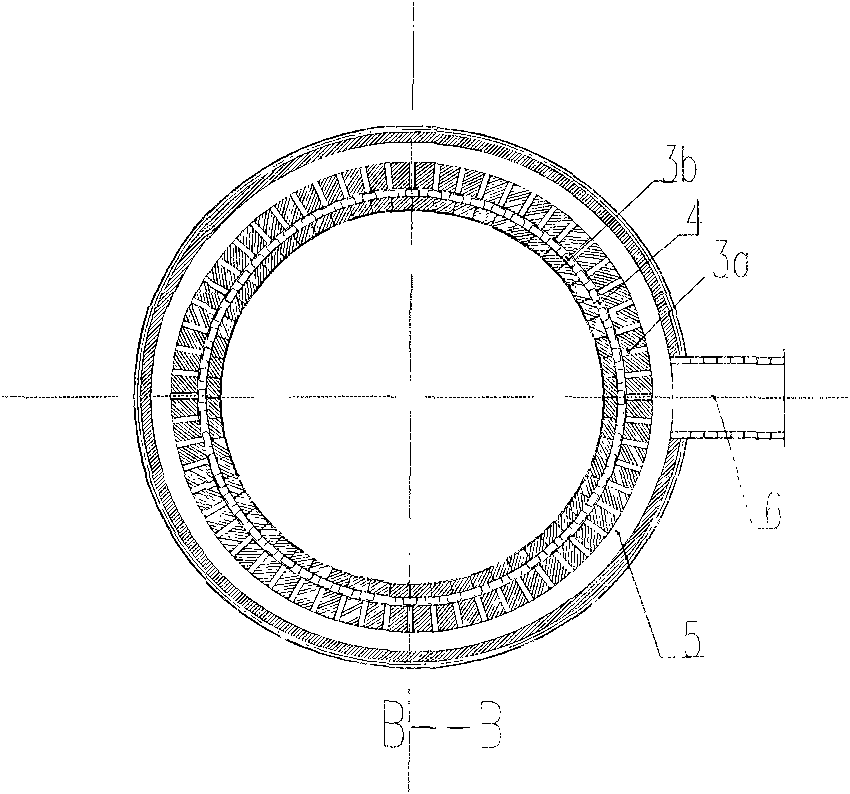

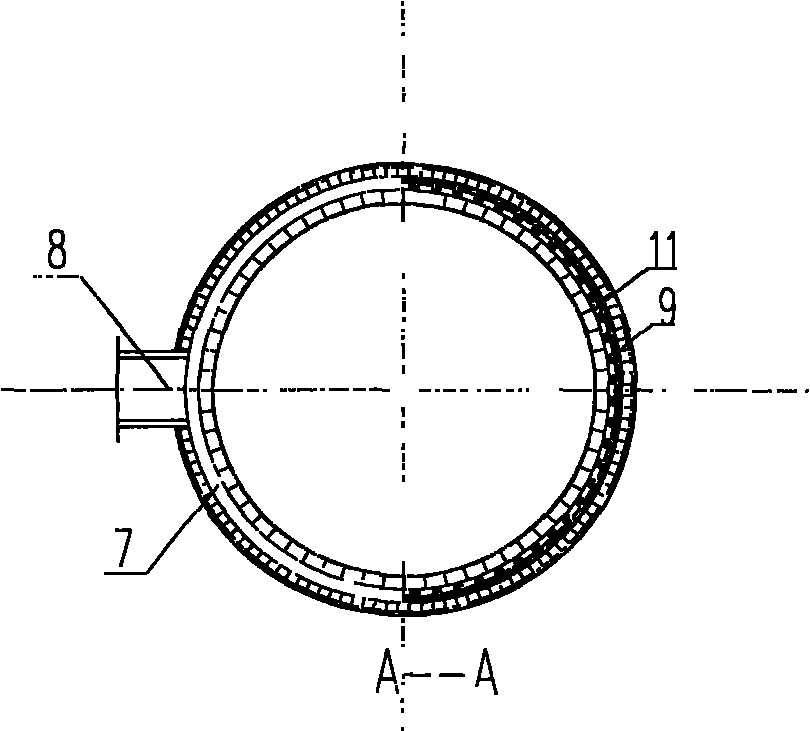

[0010] Depend on figure 1 , figure 2 ,and image 3 As shown, the overall appearance of the hot blast stove of the present invention is a bullet-shaped structure, including a combustion chamber 1 with an egg-shaped vault on the upper part, a burner 2 with a cylindrical structure, and gas nozzles 3a and The air nozzle 3b, the gas nozzle and the air nozzle are all connected to the gas and air premixing ring 4 on the upper part of the burner, and the gas and air are mixed in the premixing ring 4 to form an upwardly injected premixed air flow; in the ring burner In the wall of 2, the upper part is the gas distribution ring 5, and the gas inlet pipe 6 is arranged on the outer wall surface; the combustion air preheating device 9 is arranged in the large wall of the regenerator 10, and the upper part is in the wall of the burner 2, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com