Liquid guide pipe controller

A technology of controller and catheter, which is applied in the direction of textiles and papermaking, textile processing machine accessories, textile materials, etc., can solve the problems of dirty, workplace, printing raw materials waste, etc., to save printing raw materials and maintain cleanliness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

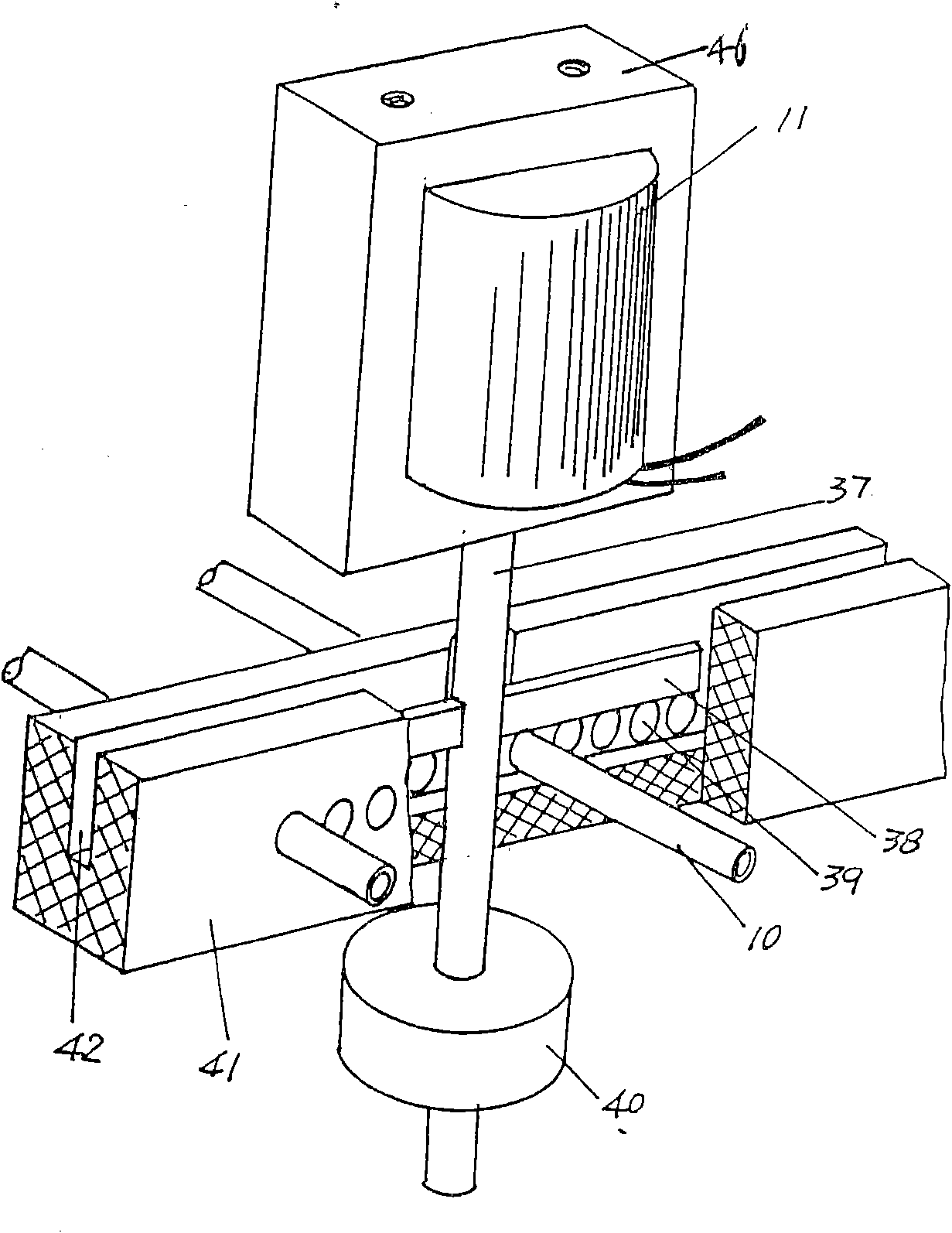

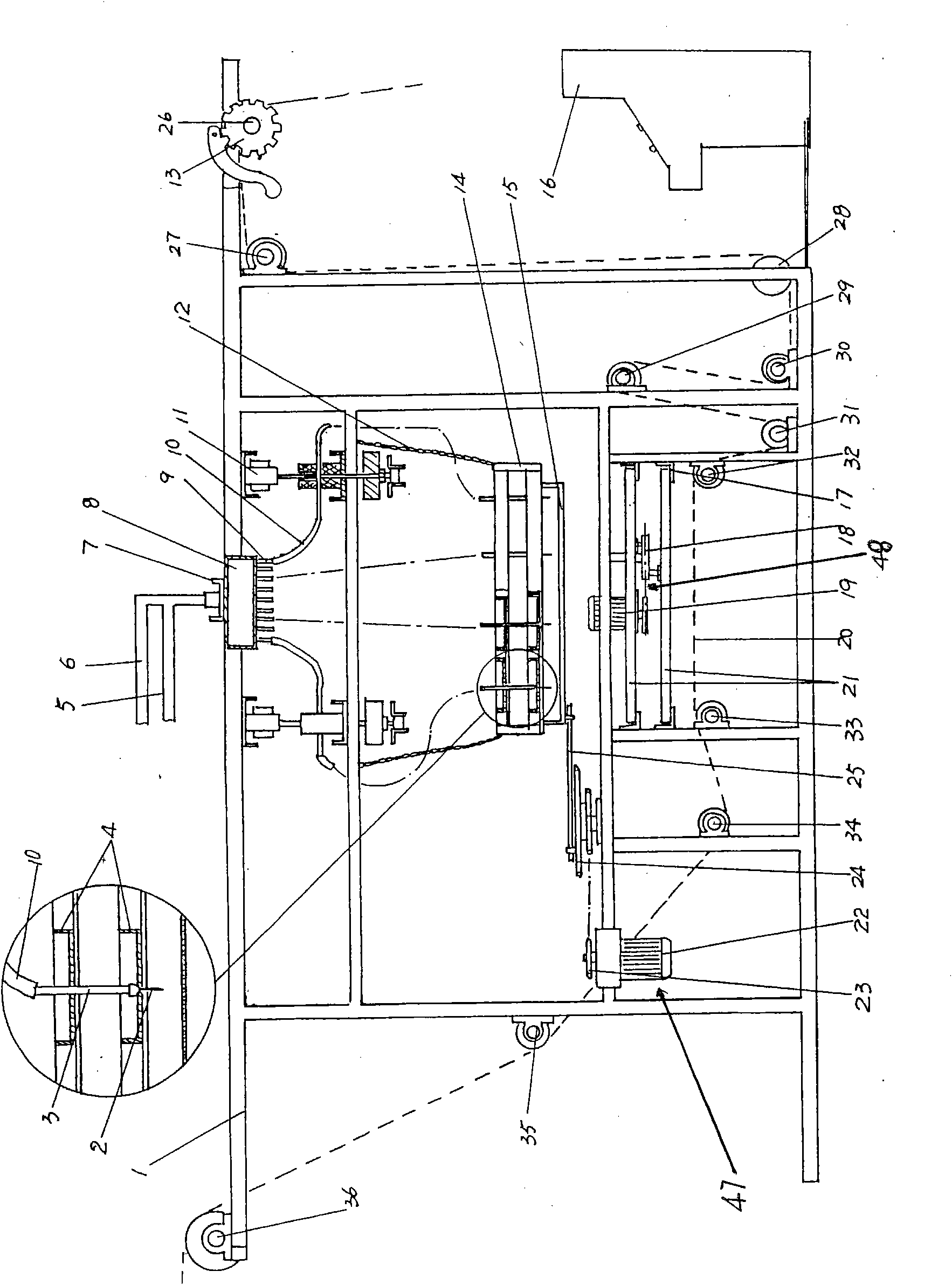

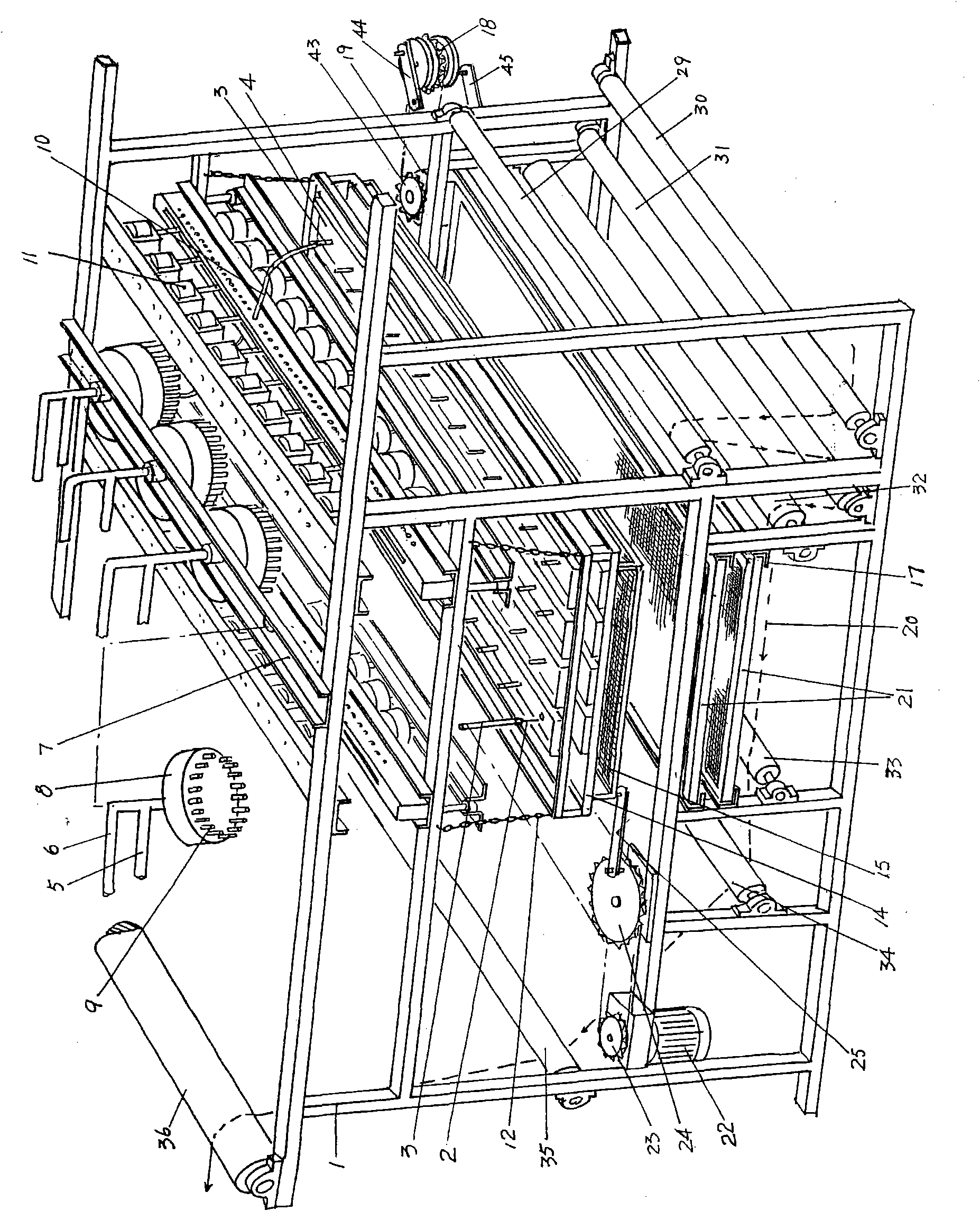

[0010] please see figure 1 and figure 2 The solenoid valve frame 46 is installed on the crossbeam 7 of the frame 1 of the woolen fabric printing machine with fixing screws, and the solenoid valve body 11 is installed in the solenoid valve valve frame 46, which is controlled by the circuit and the electrical control of the woolen woolen fabric printing machine. The platform 16 is electrically connected, and one end of the spool 37 (also known as the valve rod), namely the upper end, is located in the solenoid valve body 11, and the other end, namely the lower end, passes through the bead seat 41 and fixes a valve hammer 40. Depend on figure 2 As shown, the bead seat 41 is fixed on the frame 1, a bead groove 42 is provided in the length direction of the bead seat 41 and a group of conduit holes 39 are provided at intervals, the conduit holes 39 communicate with the bead groove 42 and Corresponding to the bottom of the bead groove 42 , the bead groove 42 is equipped with a be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com