Safe evaluating method for pressure vessel after short-time firing

A technology of pressure vessels and evaluation methods, applied in the field of safety evaluation of pressure vessels, can solve problems such as safety evaluation of pressure vessels without fire

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

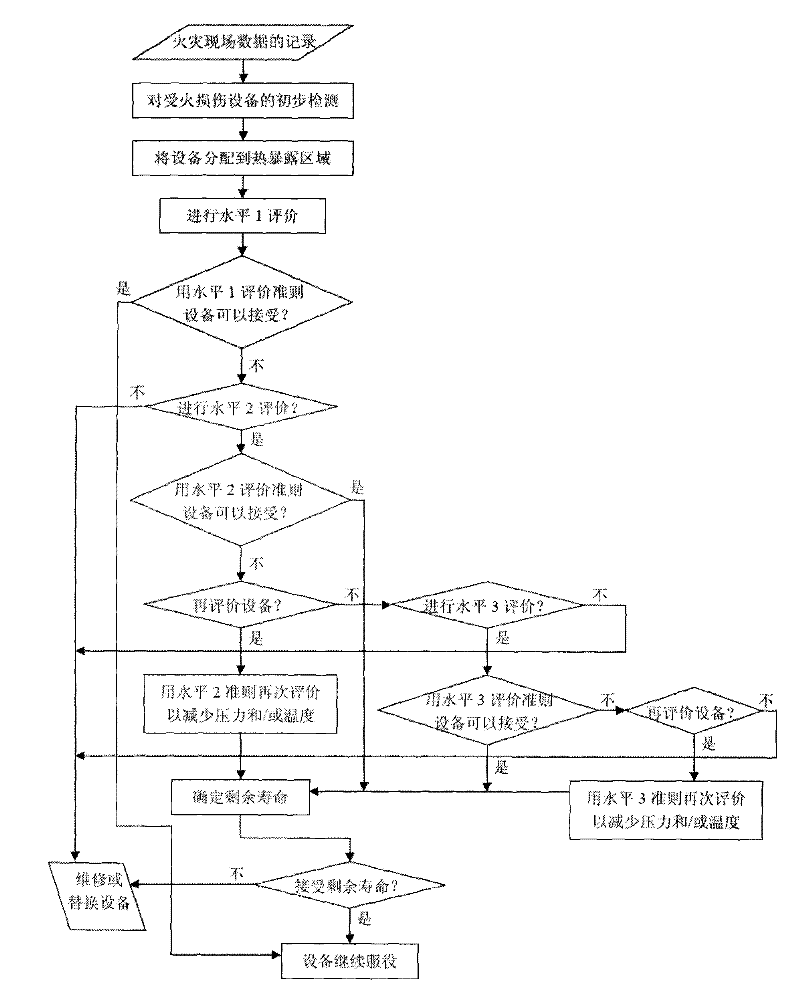

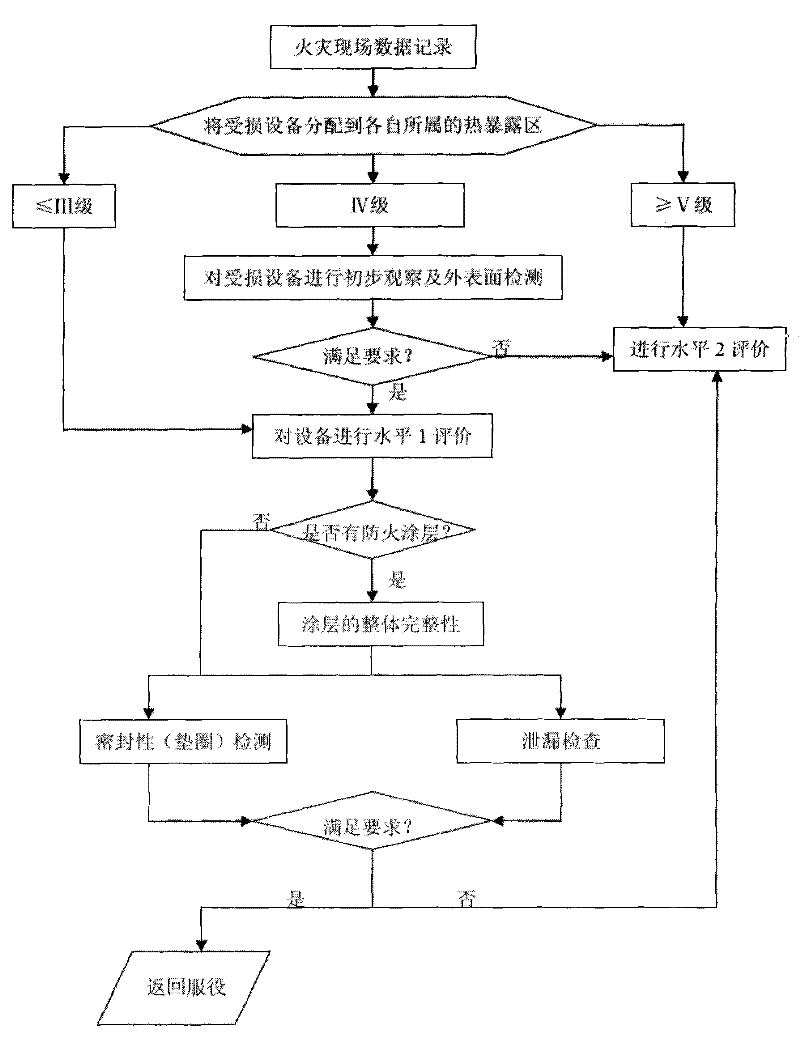

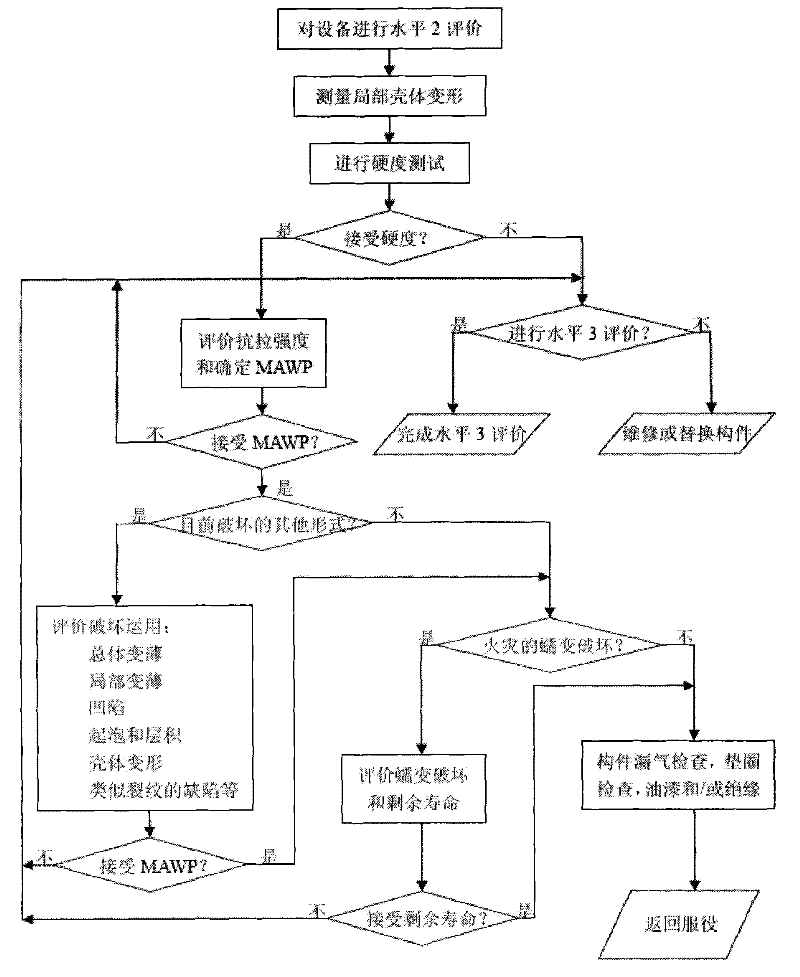

Method used

Image

Examples

example 2

[0198] Engineering example 2: Still taking the above-mentioned pressure vessel as an example, the maximum temperature experienced by the pressure vessel in a fire is between 600 and 800°C. Therefore, in terms of the distribution of heat exposure areas, this vessel is located in the V-level and VI-level range. According to the evaluation criteria, it is evaluated at level 3. Severe distortion or denting of fire-exposed equipment was first observed, and hardness testing indicated soft material. The material in the parts is further taken out to make a test piece, and the impact test is done, and the test result is obviously lower than the strength requirement. In addition, the equipment cannot be normalized and heat treated, only parts of the affected area can be replaced. Finally for the replacement of the affected part, radiographs of all new welds meet the requirements. Welding repairs shall comply with all code and engineering requirements. Then, according to the reliabili...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com