Material and method for manufacturing carbonate cave oil reservoir physical model

A physical model, carbonate rock technology, applied in the field of physical models and physical simulation experiments

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

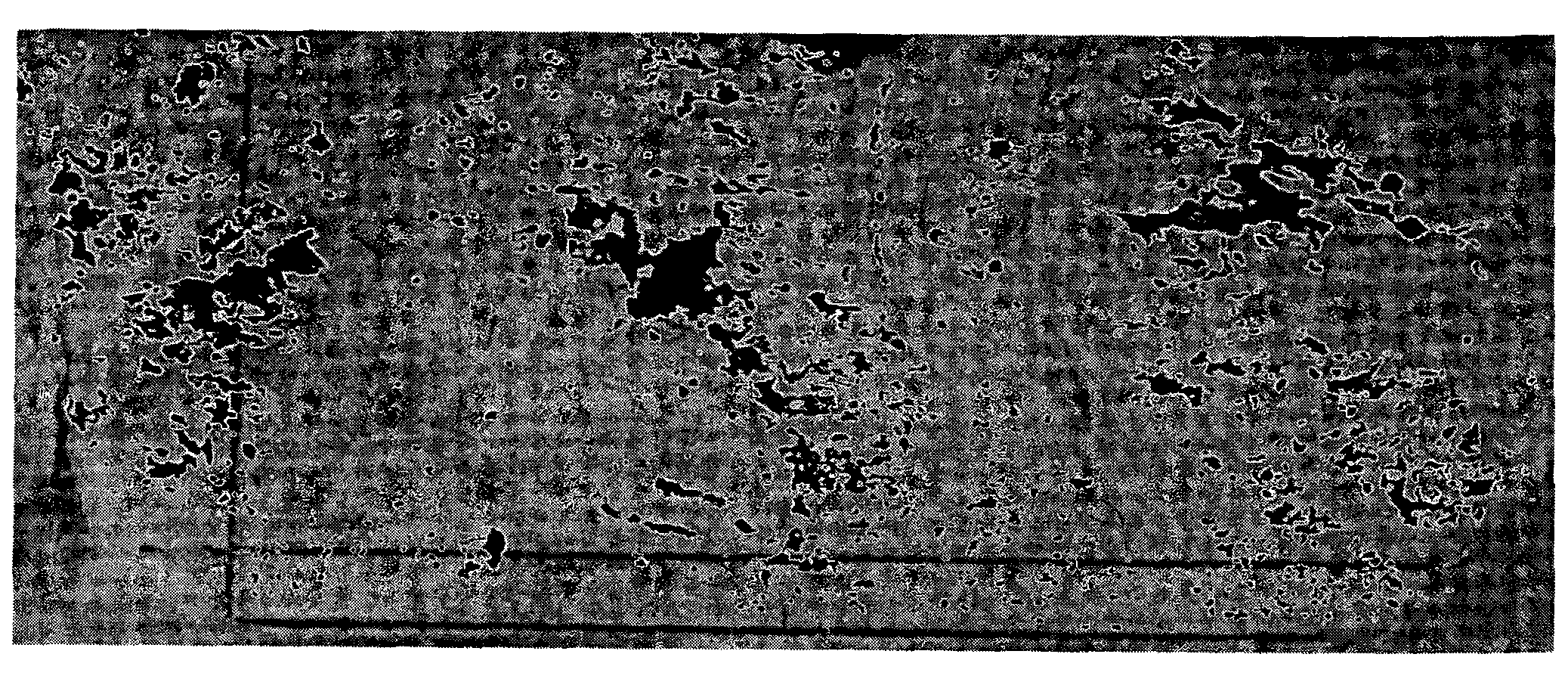

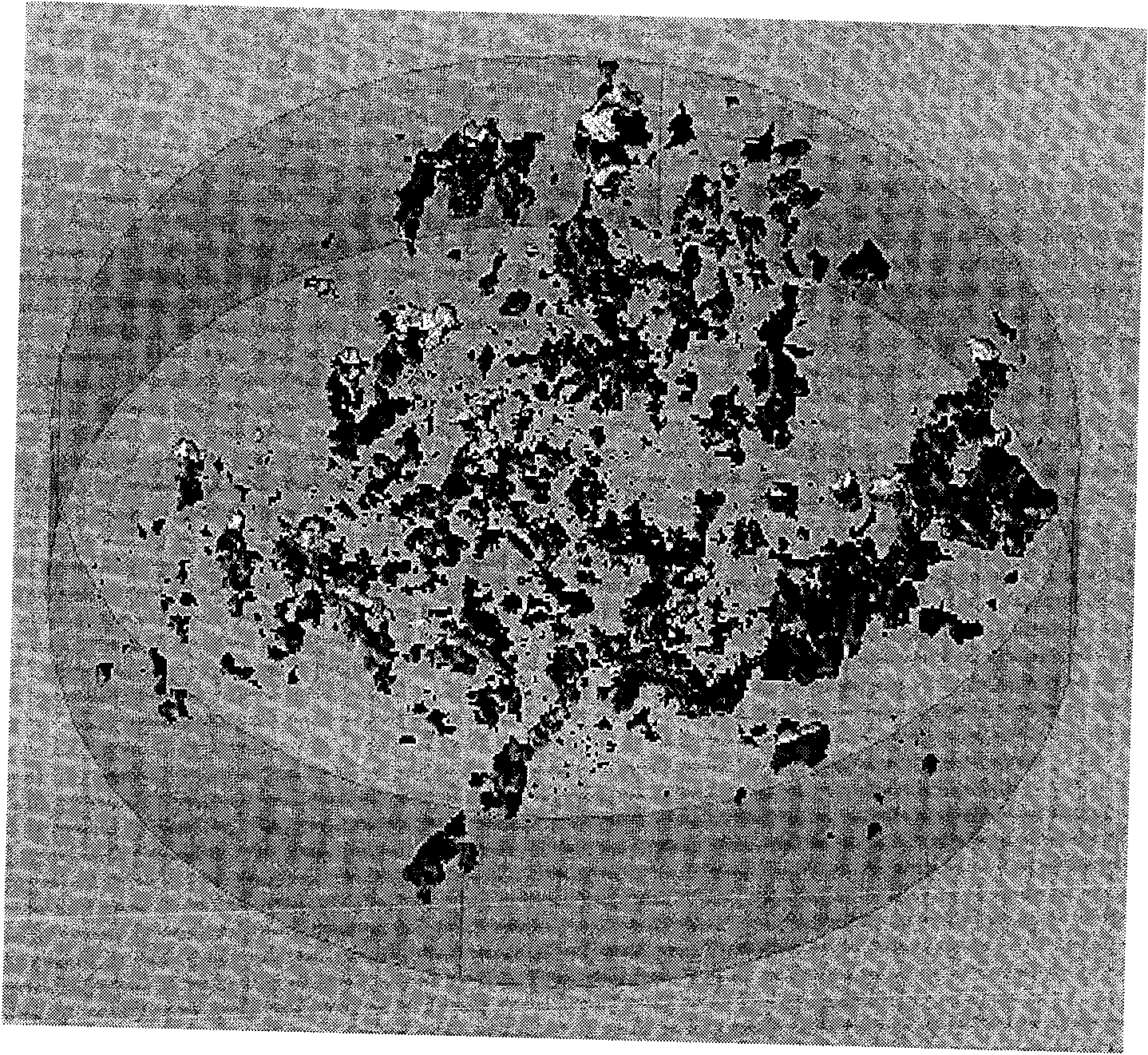

[0042] The invention mainly includes the selection of skeleton materials, mainly using calcite, dolomite and a small amount of basalt fiber as skeleton materials for constructing physical models. Slaked lime, cement and water glass are used as cementing agents. Wood metal, paraffin and heavy asphaltenes are used as materials for making crack caves. Different proportions can make physical models of fracture-cavity shapes and strengths with different specifications.

[0043] Because Wood's metal and paraffin have the characteristics of being able to become liquid at high temperatures, the present invention selects Wood's metal and paraffin as the main material for making cracks in the cave. First, caves and cracks of different sizes and shapes are made with Wood alloy and paraffin. After the entire model is formed, Wood alloy and paraffin are displaced at high temperature to form crack caves with spatial structure.

[0044] Selection of skeleton material for physical model: Ca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com