Production plan method based on limited capacity and simulation system

A technology for production planning and simulation systems, applied in computing, instrumentation, data processing applications, etc., can solve problems such as high randomness, poor accuracy and scientificity, time-consuming and labor-intensive work, and achieve enhanced feasibility and robustness. The effect of improved performance and accuracy, strong scientificity and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

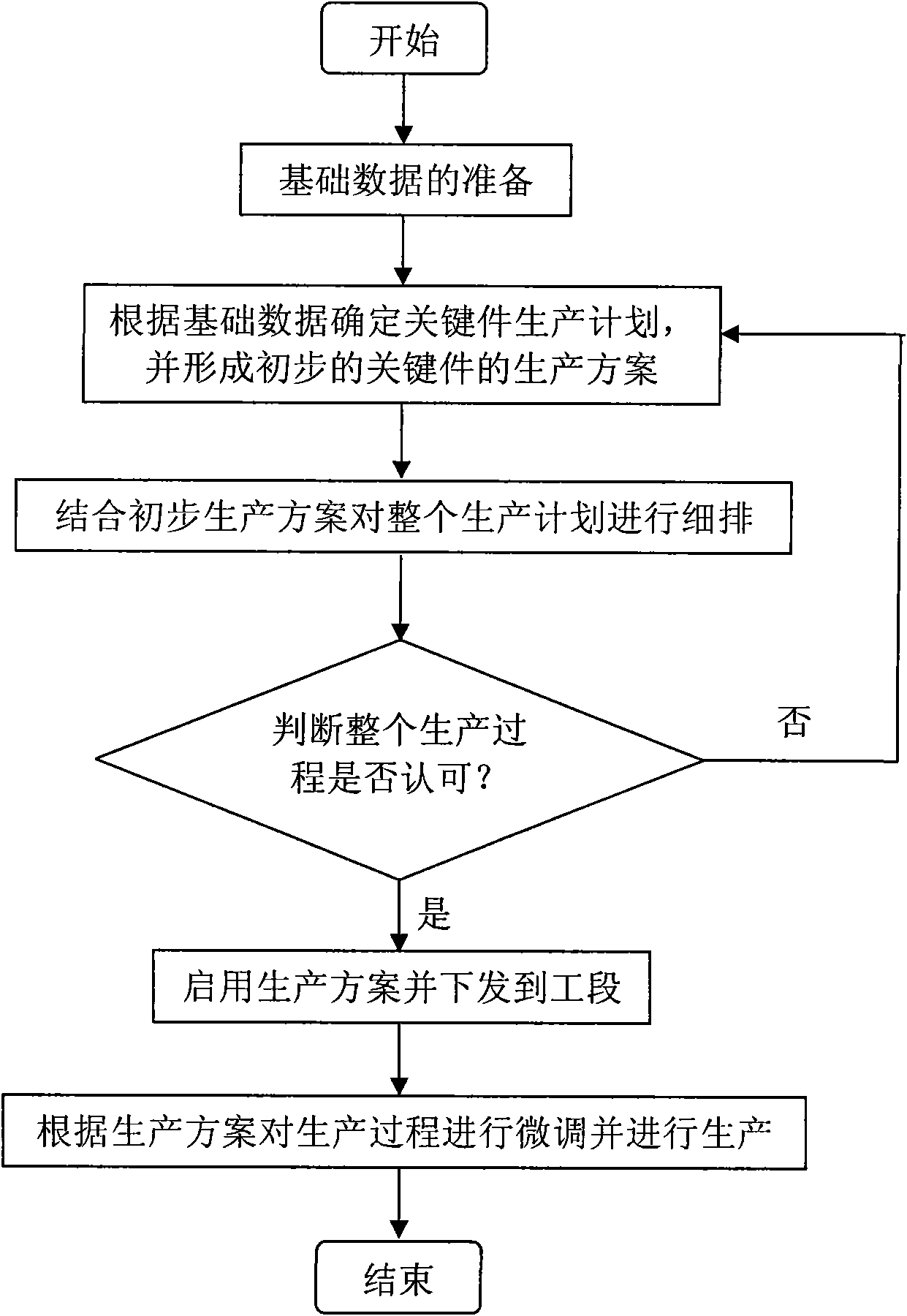

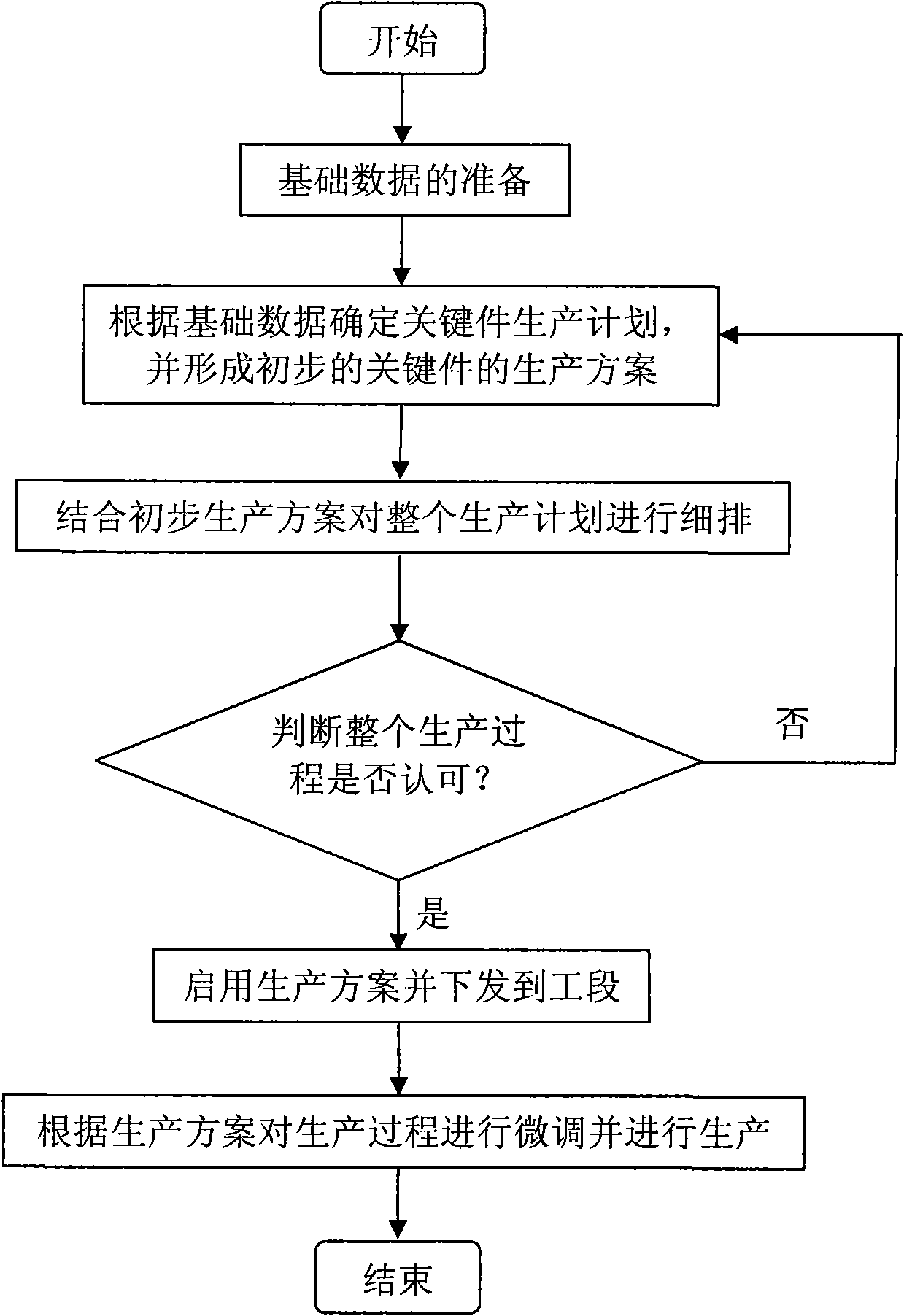

[0042] see figure 1 , the present invention provides a method for production planning under limited capacity, the method includes the following steps:

[0043]1) Preparation of basic data, the basic data includes: acquisition of production tasks, parts and components relationship, parts delivery date, production equipment calendar, production equipment replaceable relationship, acquisition of parts processing network diagram and task status and on-site synchronization data;

[0044] 2) Determine the production plan of key parts according to the basic data, and form a preliminary production plan for key parts; the specific steps are:

[0045] 2.1) Determine the key parts in OEM components;

[0046] 2.2) Call key parts level and resource level to determine the priority of key parts processing;

[0047] 2.3) Determine the key parts production plan according to the priority of key parts processing;

[0048] 2.4) Customize the calendar plan for reserved capacity according to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com