Stack type package structure and manufacture method thereof

A technology of packaging structure and manufacturing method, applied in semiconductor/solid-state device manufacturing, semiconductor/solid-state device parts, semiconductor devices, etc., can solve problems such as sticking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

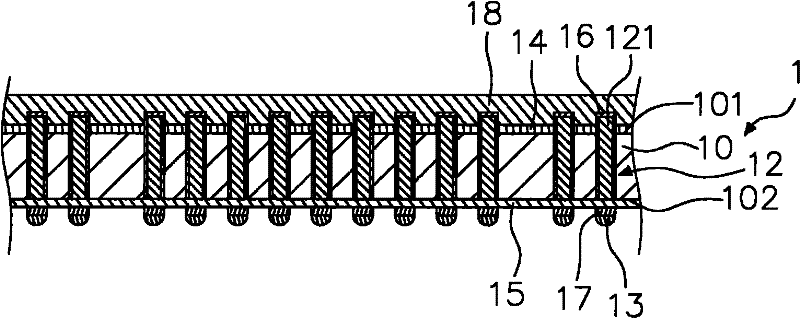

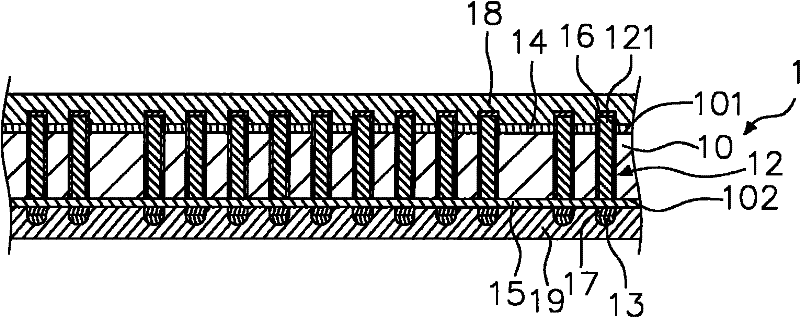

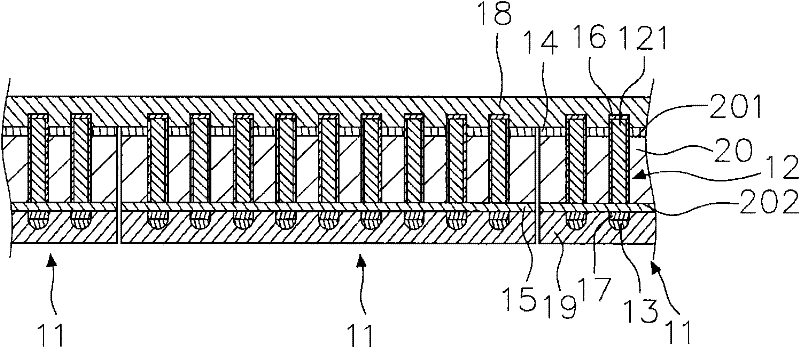

[0011] refer to Figures 1 to 14 , is a schematic diagram showing the first embodiment of the manufacturing method of the stacked package structure of the present invention. refer to figure 1 , providing a first wafer 1 and a tape (Tape) 18 . The first wafer 1 includes a first wafer body 10 , a plurality of first through silicon vias (TSVs) 12 and a plurality of first bumps 13 . The first wafer body 10 includes a first surface 101 and a second surface 102 . The first connecting pillars 12 pass through the first wafer body 10 , and one ends 121 of the first connecting pillars 12 protrude from the first surface 101 . The first bumps 13 are adjacent to the second surface 102 and electrically connected to the first vias 12. In this embodiment, the first bumps 13 are stacks of copper pillars and solders. structure. In other embodiments, the first bumps 13 may only be copper pillars or solder. The adhesive tape 18 is adjacent to the first surface 101 to cover and protect the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com