Light-emitting diode encapsulation method and jig

A technology of light-emitting diodes and packaging methods, applied in electrical components, circuits, semiconductor devices, etc., can solve problems such as uneven glue discharge, improve process efficiency, shorten detachment time, and accelerate downward flow.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Below in conjunction with accompanying drawing and embodiment the present invention is described in detail:

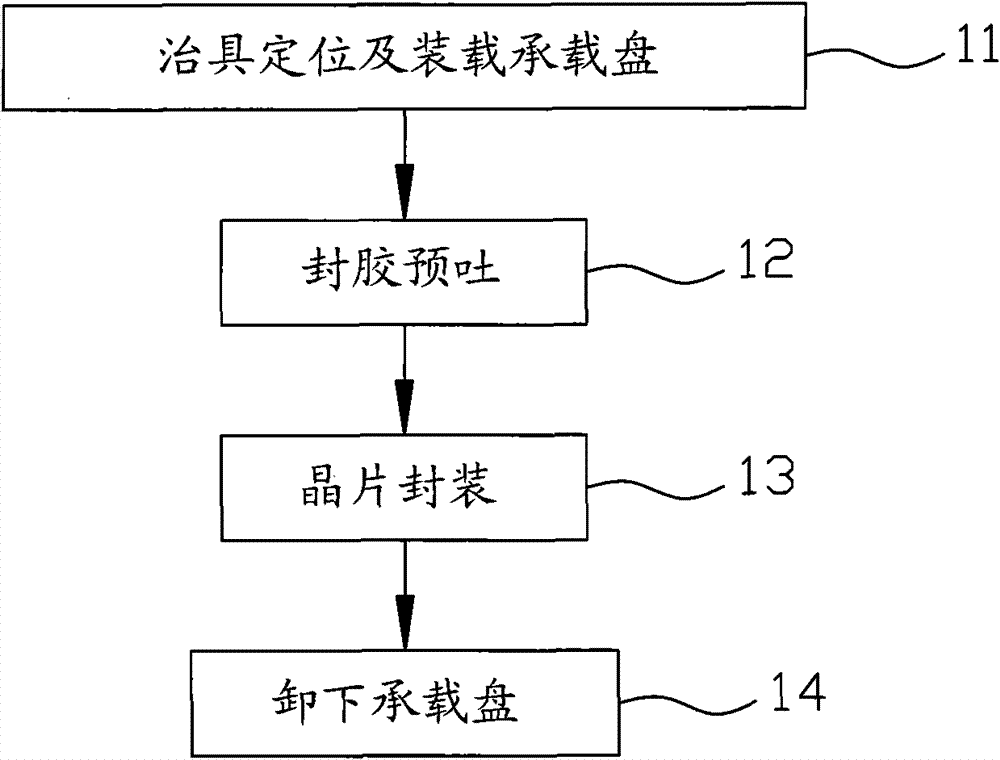

[0017] refer to Figure 1 ~ Figure 3 , a preferred embodiment of the LED packaging method of the present invention includes steps 11-14.

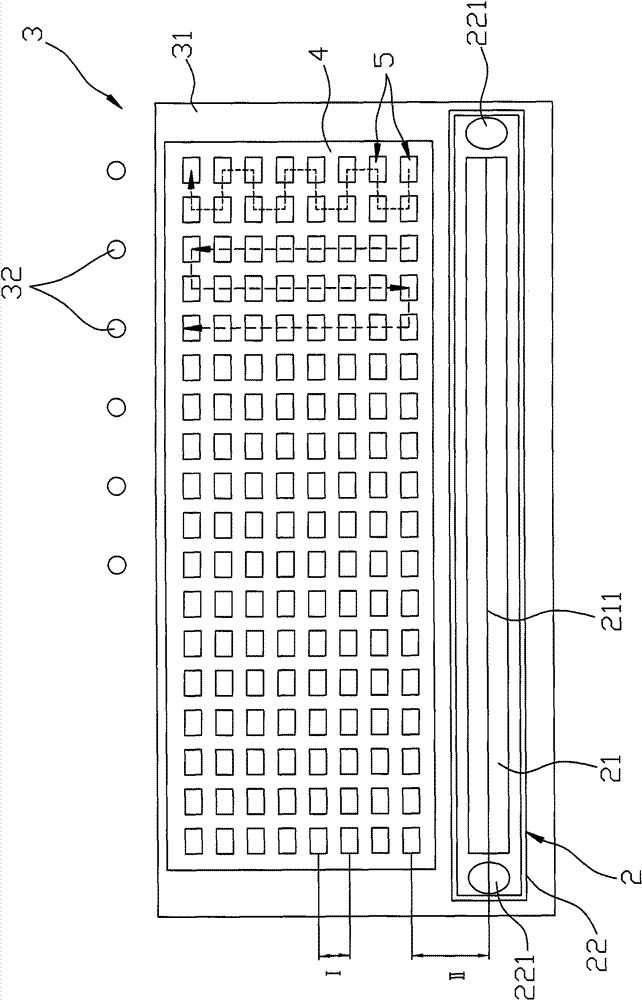

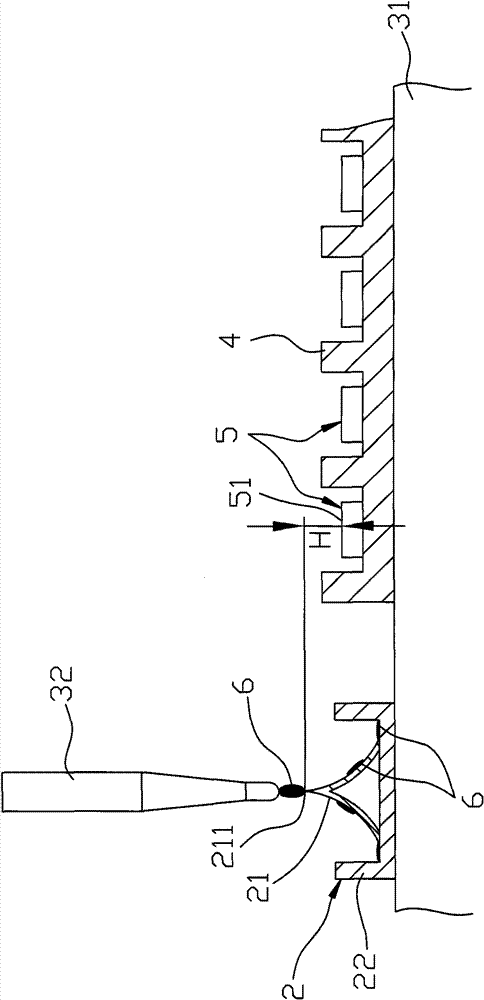

[0018] Step 11 is jig positioning and loading tray: a jig 2 is placed on a workbench 31 of a packaging machine 3, wherein the jig 2 includes a shunt rack 21, and a collection rack 21 for the shunt rack 21 The tray 22, the distribution frame 21 has a receiving portion 211 extending along a first direction of the worktable 31, and a section of the distribution frame 21 along a second direction perpendicular to the first direction of the worktable 31 is It is narrow at the top and wide at the bottom. In this embodiment, the cross-section of the distribution frame 21 along the second direction is a triangle with a sharp top and a wide bottom, and the two hypotenuses are in a concave arc shape. The collection tray 22 is used to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com