Motor control system with speed-change function and method thereof

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

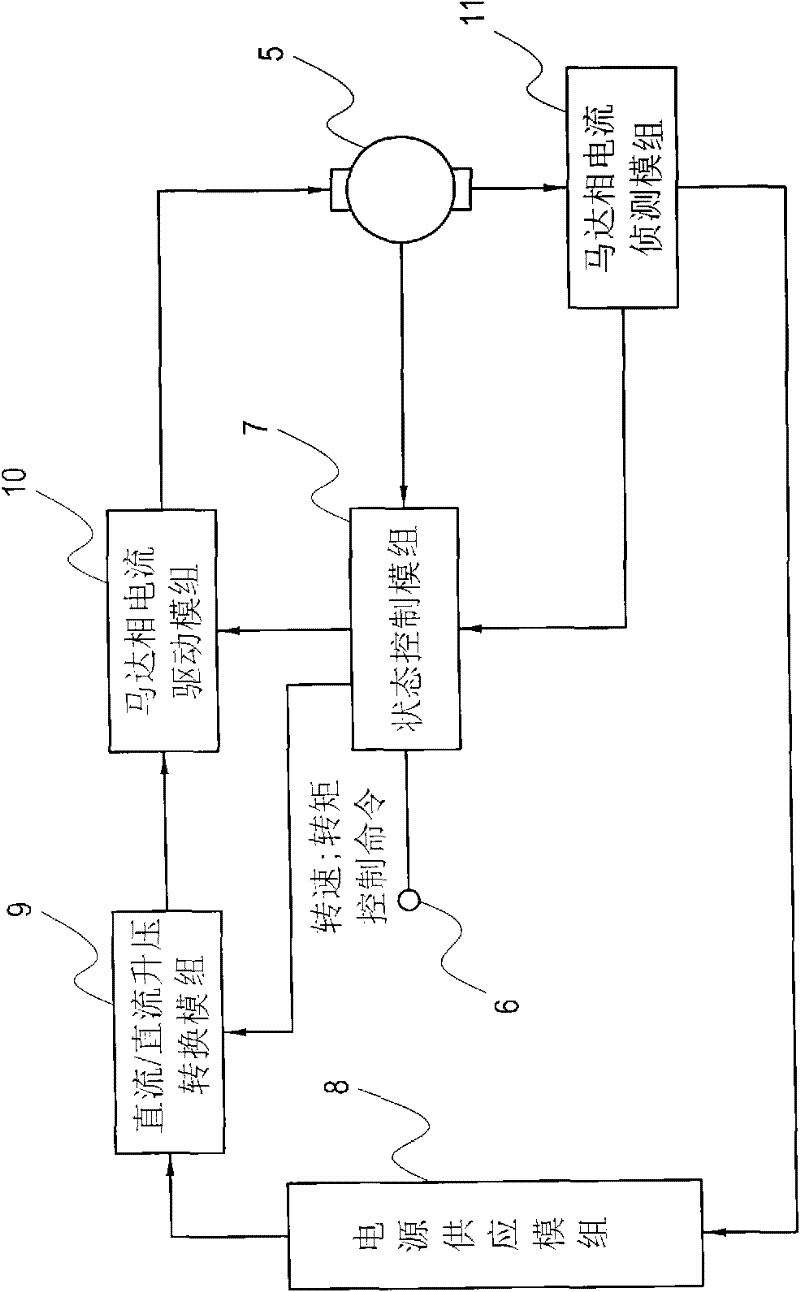

[0043] see image 3 It is a system architecture diagram of the motor control system with variable speed function and its method of the present invention, as shown in the figure, including:

[0044] A motor 5, with a built-in motor winding, can transmit phase and speed signals; in addition, the motor 5 can be a motor device such as a DC brush motor, a DC brushless motor, an AC motor, and a hub motor;

[0045] A control command receiving end 6, responsible for receiving the speed command or torque command for controlling the motor 5;

[0046] A state control module 7, receives the external control command receiving end 6 speed or torque control command, and the phase and speed signal transmitted by the motor 5, and the detection signal fed back by the motor phase current detection module 11, and Determine the PWM opening and commutation sequence according to the command or detection signal, and output the control signal to the DC / DC boost conversion module 9 and the motor phase...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com