Method and device for plugging hole by using piston during printed circuit board manufacture

A technology for printed circuit boards and plug holes, which is applied in the direction of printed circuit manufacturing, printed circuits, and the formation of electrical connections of printed components. sunken effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

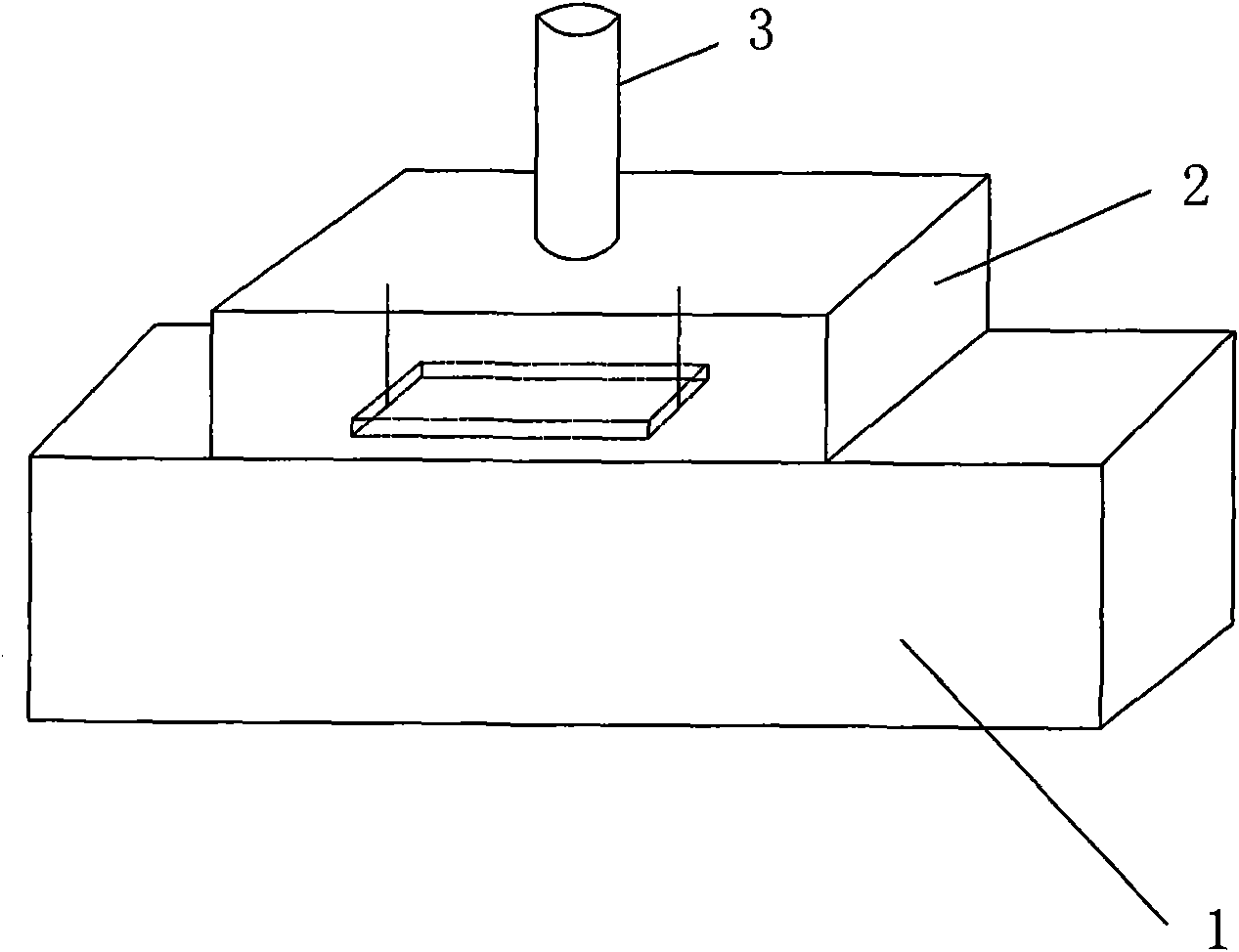

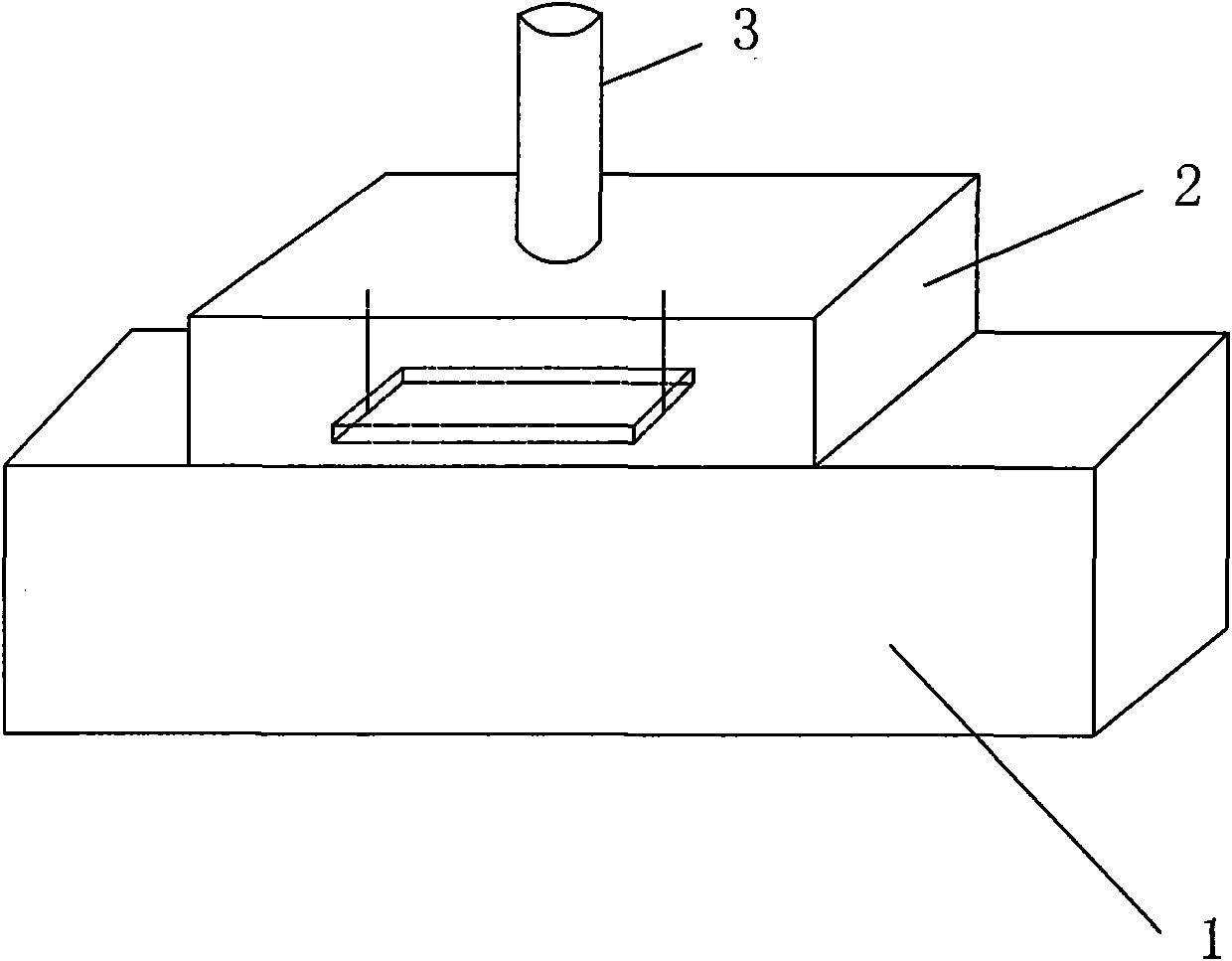

[0016] see figure 1 , the device includes a pallet 1 for placing printed circuit boards, a cavity 2 is formed on the top of the pallet 1, and the lower part of the cavity 2 is open, and a screen or a prepreg or an aluminum sheet is placed at the opening, and then placed on their A large amount of ink, resin or copper paste is preset on the top, a piston 3 is installed on the top of the cavity 2, and the surroundings of the cavity 2 are sealed. During the production process, the piston 3 of the device compresses the air in the closed cavity 2 in the through hole or blind hole of the circuit board, and then the air compresses the ink on the aluminum sheet, mesh plate or prepreg sheet covered on the circuit board. , resin or copper paste to apply pressure and fill ink, resin or copper paste into the via hole or blind hole, so that the via hole or blind hole of the circuit board is completely filled with ink, resin or copper paste, effectively preventing air bubbles And dents and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com