Automatic blending material control system for sintering production

A control system and automatic batching technology, which is applied in the direction of mixer accessories, mixers, mixing methods, etc., can solve the problem that manual operation cannot obtain stable control quality, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Preferred embodiments according to the present invention will be described in detail below with reference to the accompanying drawings. Those skilled in the art will understand the features and advantages of the present invention from the accompanying drawings and corresponding descriptions.

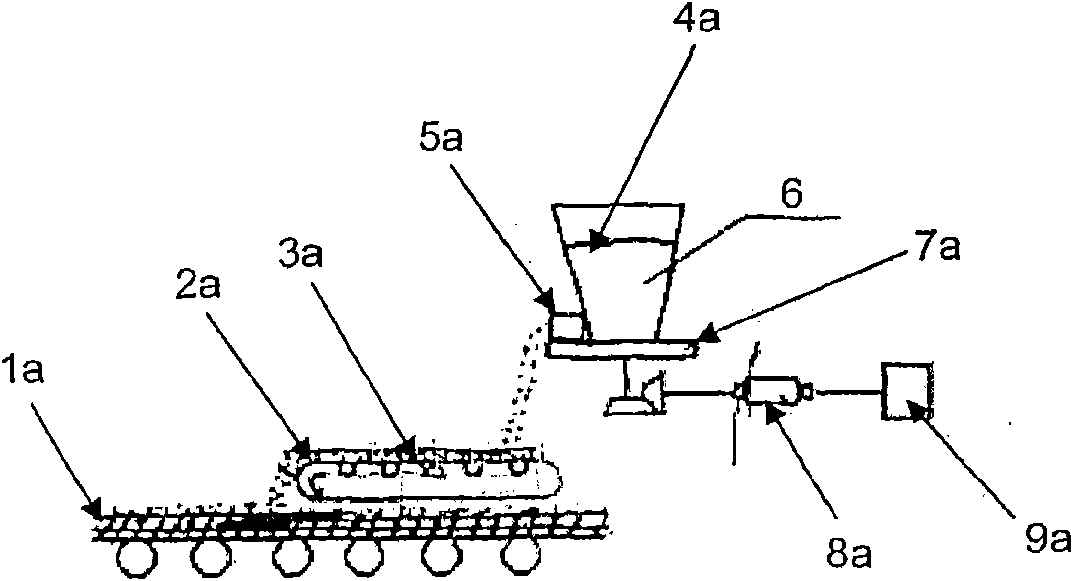

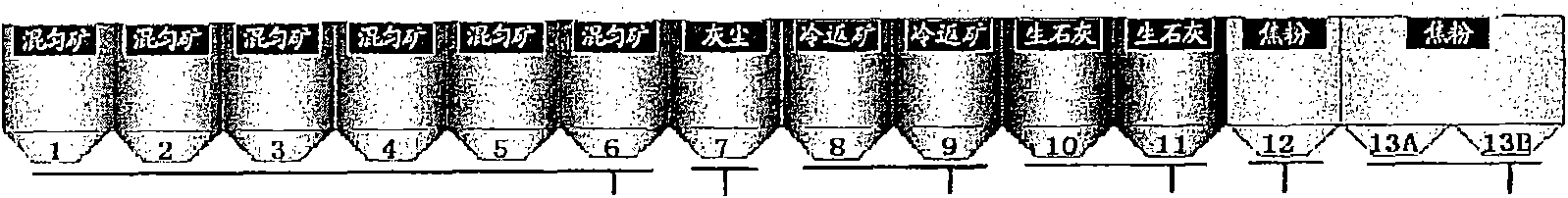

[0023] figure 1 A schematic diagram of the feeding system of one of the mixed ore batching silos 6 according to the present invention is shown, and the feeding systems of other batching bins may also have the same or similar configuration. in the attached figure 1 Shown in the figure is a part of the total batching belt 1a, weighing belt 2a, weighing pressure sensor 3a, sintering raw material 4a, feeding bin door 5a, one of the batching bins 6 for mixing ore, weighing type level gauge (not shown), batching disc 7a, motor 8a and frequency converter 9a.

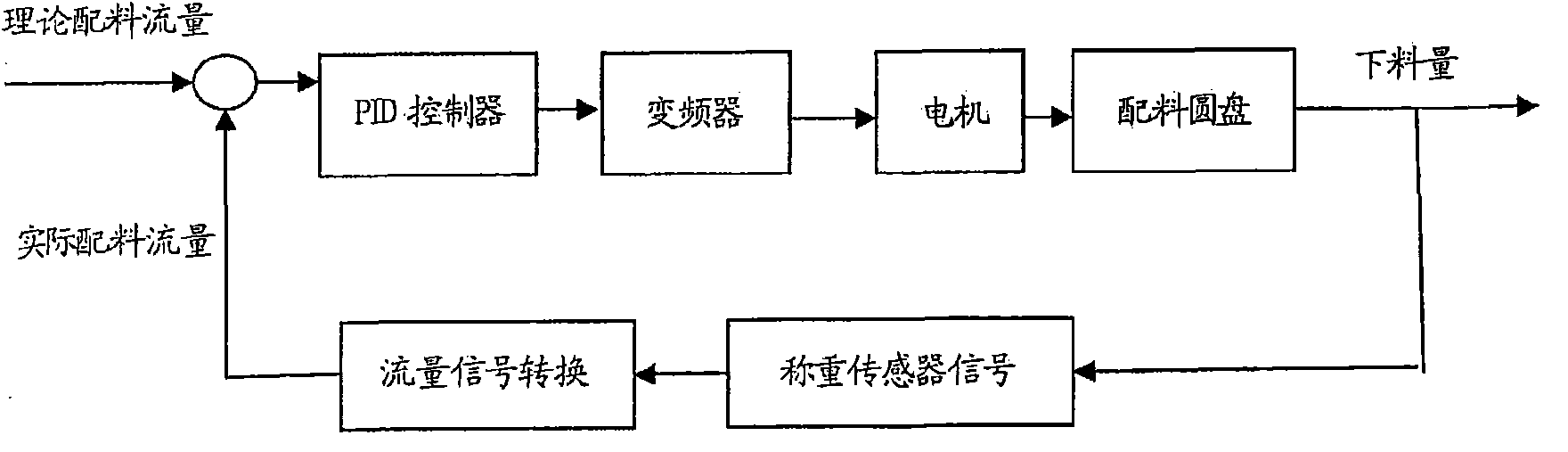

[0024] On the sintering ingredient production line in the present invention, the frequency converter 9a controls the rotating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com