Grinding device of upper guide bearing bushing and lower guide bearing bushing of hydroelectric unit generator

A grinding device and guide bearing pad technology, which is applied in the direction of grinding devices, grinding machine tools, metal processing equipment, etc., can solve the problems of the size and weight of the grinding device, the inconvenient use of the operator, and the large shape of the grinding device. Short cycle, shortened installation cycle, and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

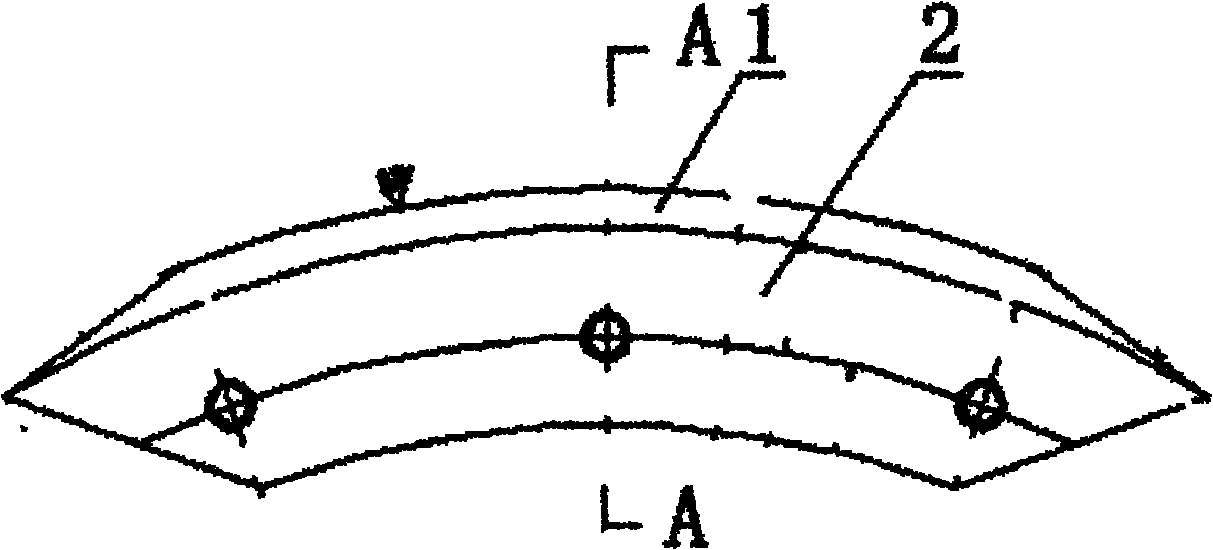

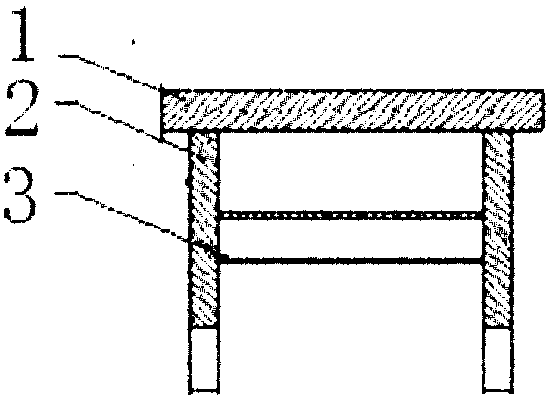

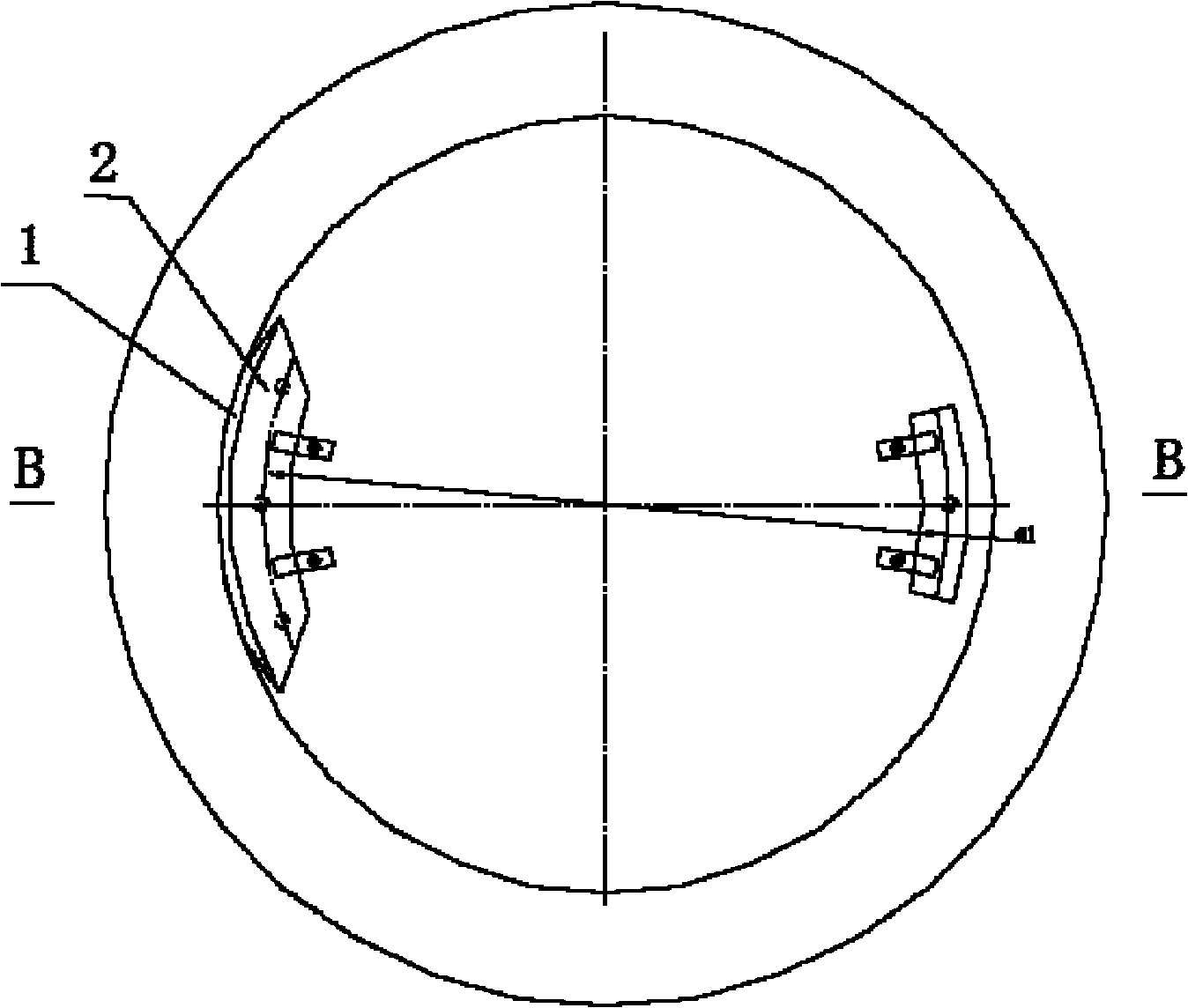

[0025] A grinding device for the upper and lower guide bearing bushes of a hydroelectric unit generator, which is fan-shaped and semi-box-shaped, and has a 50° arc steel plate 1, and two webs 2 are welded on the inner side of the arc steel plate 1, and there are supports between the webs 2 steel pipe 3. There are wedge-shaped chamfers at both ends of the arc plate 1 . The arc steel plate 1 is a 35# steel plate, and the inner side is welded with two width plates 2 and then overall annealed. After annealing, wedge-shaped chamfering at both ends, turning and honing are performed. Circular arc steel plate 1 adopts 35# steel plate, which is suitable for honing processing and meets the requirement of roughness Ra0.4 on the outer surface of the arc.

[0026] The specific structure and process of this embodiment:

[0027] The grinding device for the upper and lower guide bearing pads of the generator of the hydroelectric unit has a fan-shaped structure, and the device adopts a half-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com