Bottle cap

A bottle cap and oil bottle technology, applied in the field of bottle caps, can solve the problems of wasting resources, reusing other uses, not being an environmental protection, and achieving the effect of improving work efficiency and reducing recycling costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

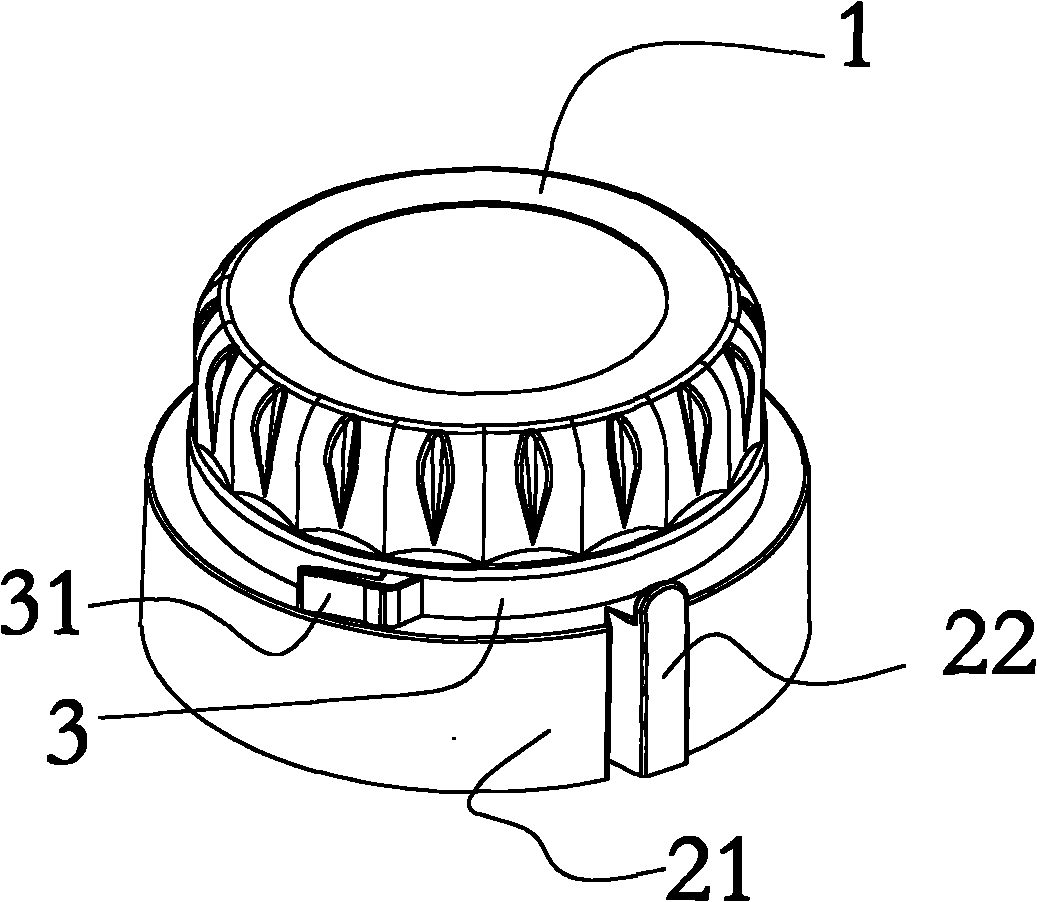

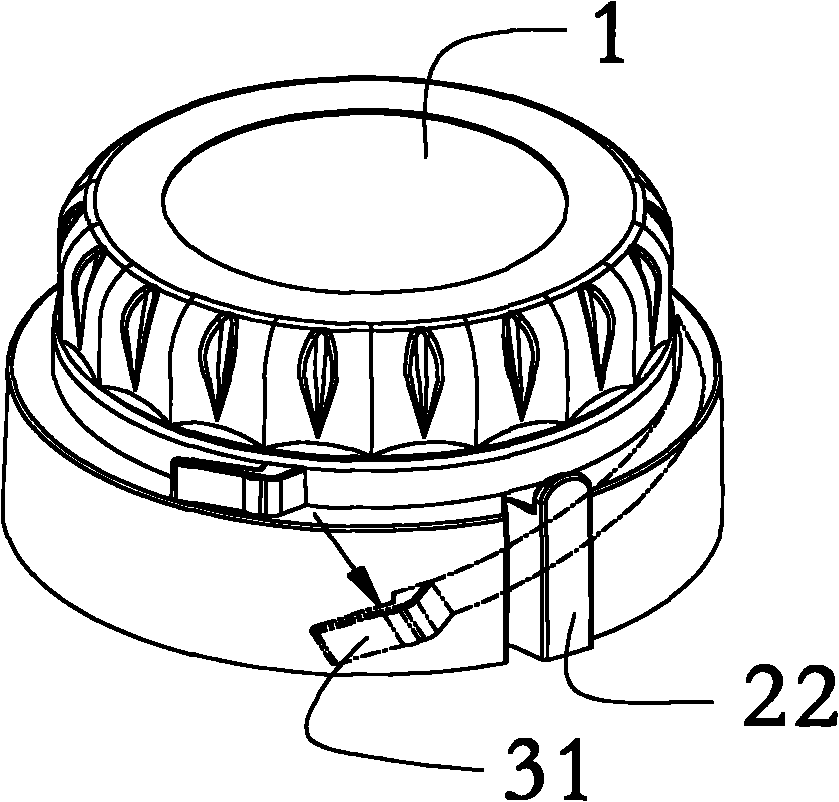

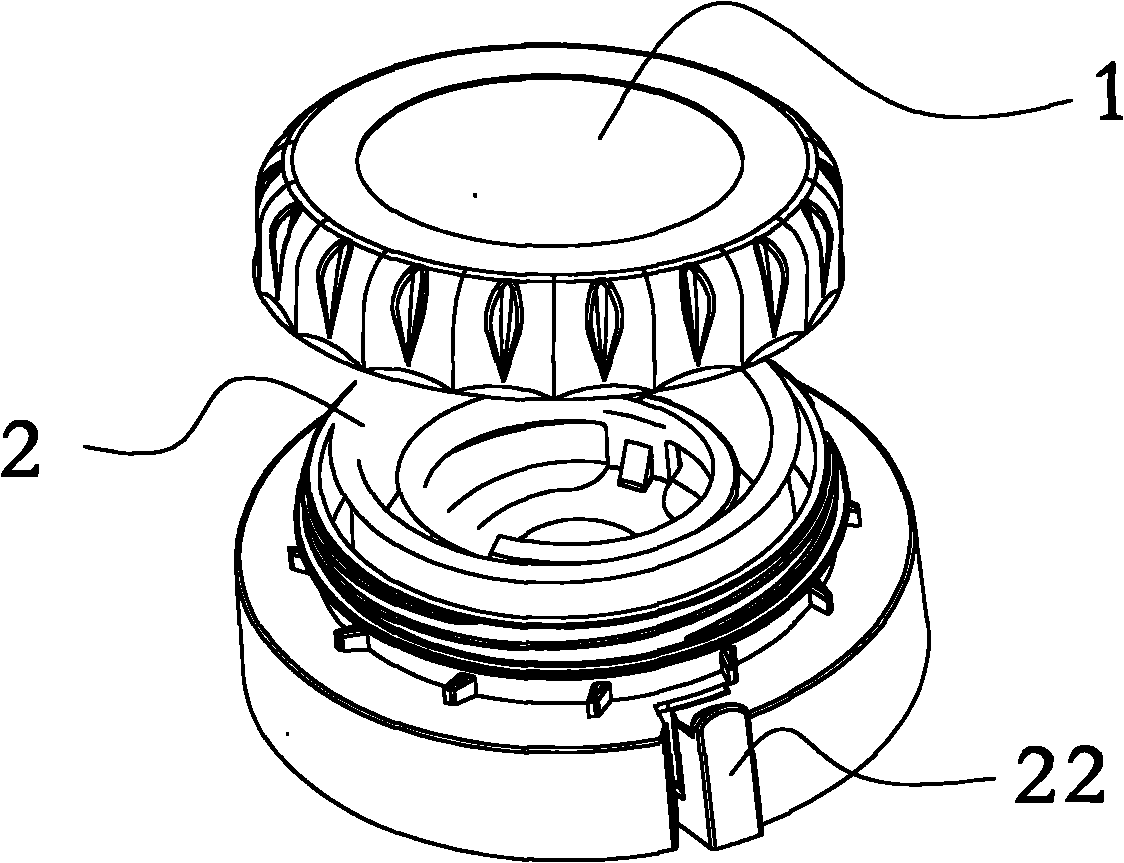

[0019] Such as Figure 1 to Figure 4 A bottle cap shown is used for large-capacity oil bottles, and includes an upper cover 1, a lower cover 2 and an anti-theft ring 3, and the anti-theft ring 3 and above are the upper cover 1, as Figure 5 , below the anti-theft ring 3 is the lower cover 2 (such as Figure 6 ). After the upper cover 1 and the lower cover 2 are injection molded separately, use a machine to press and combine the two into one, and use the undercut function to screw in and cannot be turned; the anti-theft ring 3 has a removal handle 31, and the lower cover 2 includes a recovery ring twenty one. During use, first tear off the anti-theft ring 3, open the upper cover 1 (such as figure 2 As shown), then rotate the upper cover 1 to pull off the inner ring, and then it can be used. After the use is complete, after the empty b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com