Re-manufacturing method of engineering machinery axle and coating of engineering machinery axle

A technology for construction machinery and remanufacturing, applied in the direction of coating, metal material coating process, melt spraying, etc., can solve the problem of not meeting the technical requirements for remanufacturing of construction machinery shaft parts, and achieve good fluidity and excellent performance. , the effect of narrow particle size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

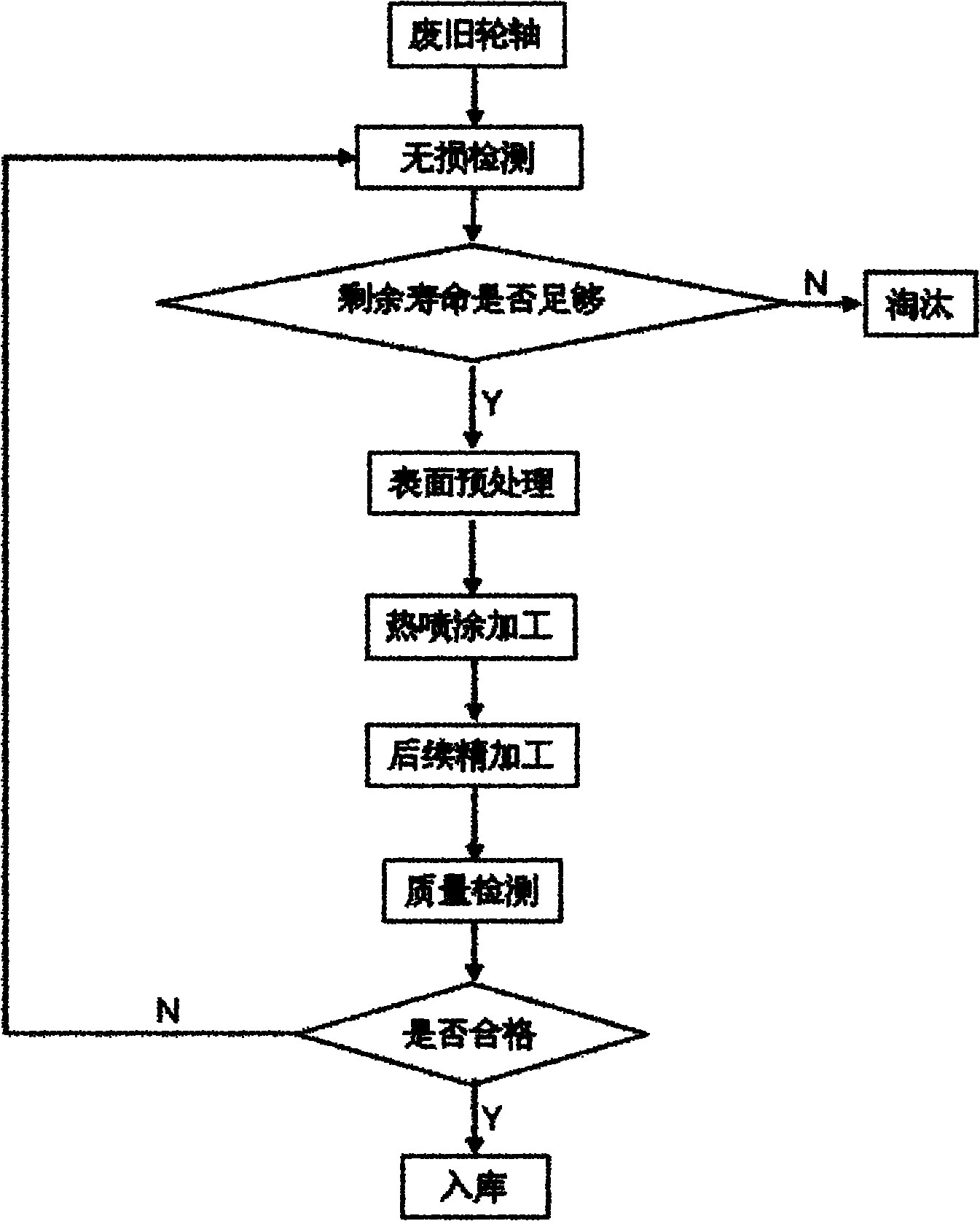

[0030] The remanufacturing method of construction machinery axles provided by the present invention mainly consists of four steps: carry out non-destructive testing on waste axles to judge their remaining life; carry out surface cleaning and turning pretreatment on them to remove rust and oil Make its geometric dimensions regular; perform plasma spraying or supersonic flame spraying remanufacturing processing on it to restore and improve its performance; carry out subsequent finishing and testing on it to evaluate the quality of remanufactured parts.

[0031] figure 1 It is a schematic diagram of the remanufacturing process of waste wheel axles of construction machinery.

[0032] The remanufacturing process of the used wheel shafts of construction machinery is as follows: First, conduct non-destructive testing on the disassembled used wheel shafts to screen out parts with sufficient remaining life; then, clean them to remove oil and surface impurities, and clean the surface D...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com