Superfine fiber artificial leather and manufacturing method thereof

A technology of ultra-fine fibers and manufacturing methods, which is applied in chemical instruments and methods, textiles and papermaking, textiles, etc., can solve the problems of insufficient three-dimensional fibers of artificial leather, cannot meet the use requirements, and sparse surface fluff, etc., to achieve dimensional stability, Excellent mechanical properties and strong leather feeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

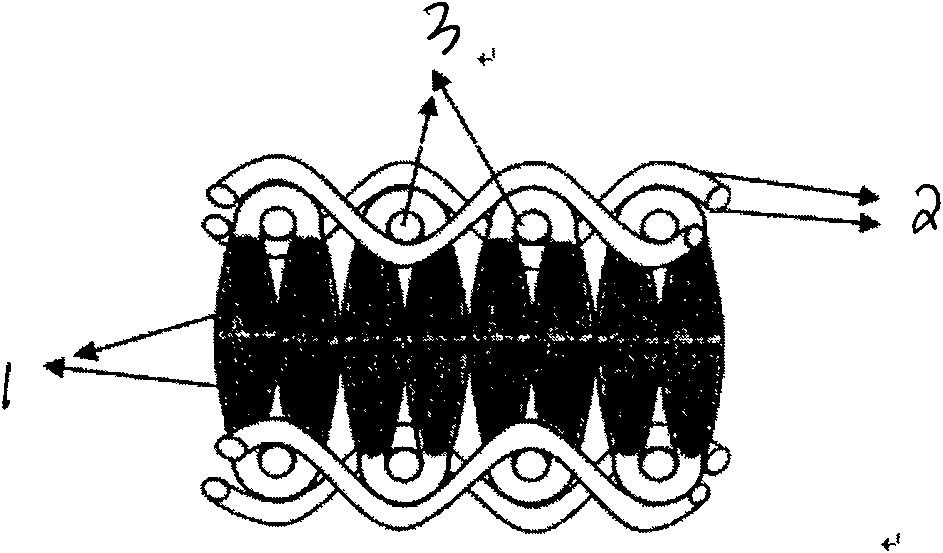

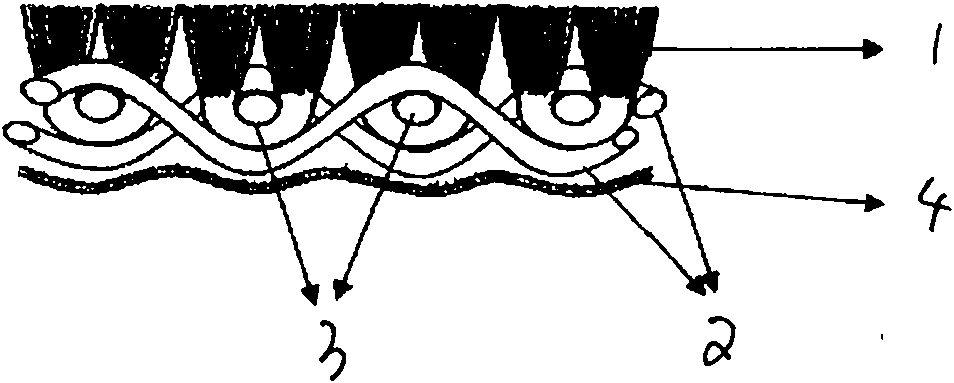

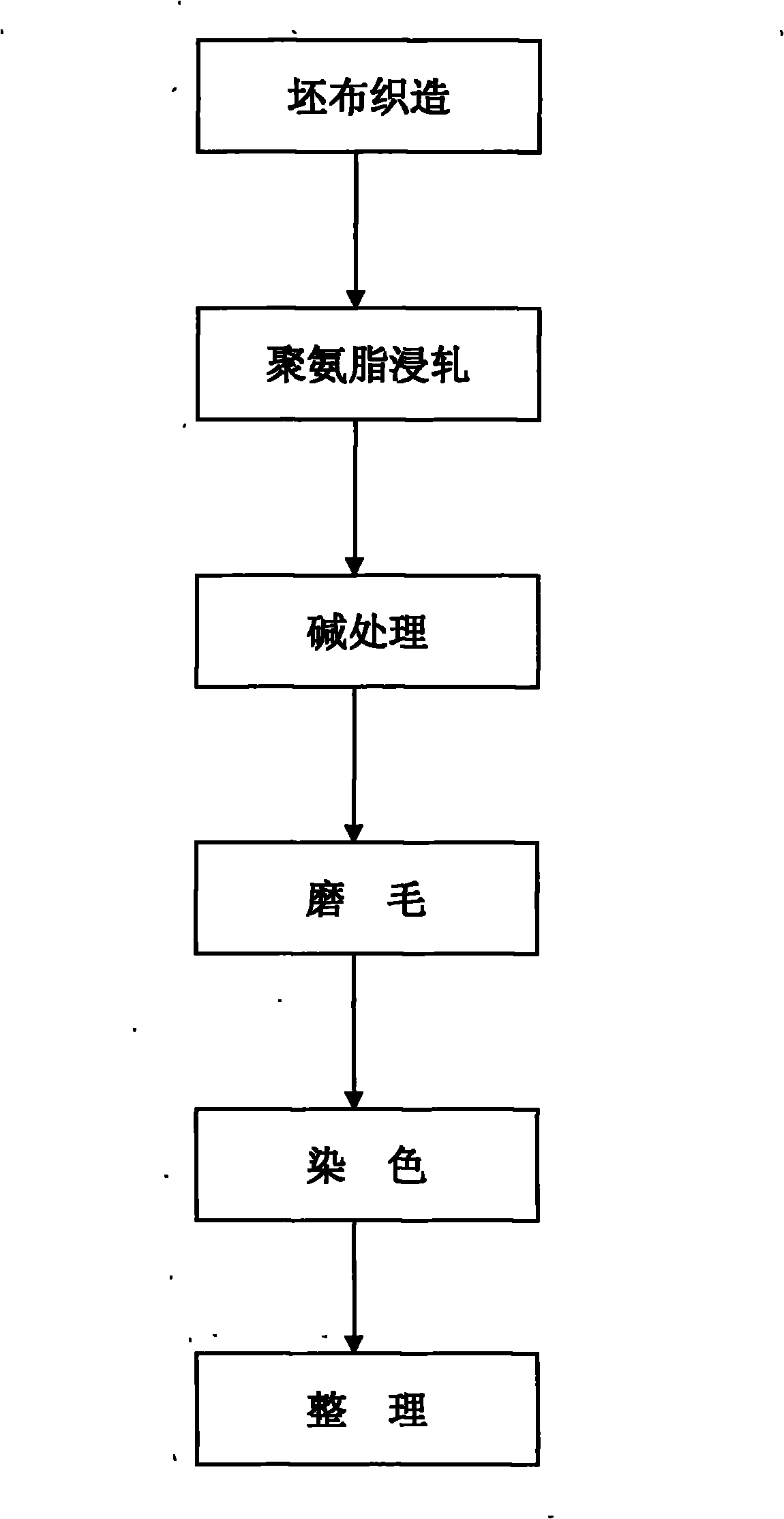

[0043] 1. Select the polyester sea-island superfine fiber whose fineness is 82.5-333dtex (preferably the fineness of superfine fiber monofilament is below 0.55dtex) as the suede warp (1), and use the fineness of 82.5-222dtex high chemical fiber as the ground Warp (2), ground latitude (3), suede warp (1) adopts V font (as figure 2 or image 3 shown) or W font (such as Figure 4 Shown) consolidation, through the double-layer warp pile weaving technology, weaving double-layer fleece gray cloth on the pile loom (such as Figure 5 As shown), the velvet warp thread connecting the two layers of ground fabric is cut off by the cashmere cutting knife, so that the double-layer gray fabric is divided into two pieces with ground warp (2), ground weft (3) and V or W shape respectively. Cashmere warp (1), called wool surface, is a three-dimensional structure of single-layer cashmere gray cloth (such as Figure 6 shown);

[0044] (2) Immerse the flannel gray cloth into 5% to 30% polyure...

Embodiment 2

[0052] The microfiber artificial leather obtained in Example 1 is detected, respectively from gram weight, thickness, TABER wear resistance, water immersion fading, normal temperature bending, burst strength, tensile strength, elongation, tear strength, friction fading, The peel strength and wet type were tested, and the test results are as follows:

[0053]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com