Rapid-installation water pipe boiler with medium and high pressure single-boiler barrel structure

A technology of water tube boiler and single drum, which is applied in the field of boilers, can solve problems such as weakening of hole bridges, occupation, and increase of drum wall thickness, and achieve the effects of reducing manufacturing difficulty, reducing manufacturing costs, and saving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The following is a further detailed description of the medium and high pressure single drum structure fast-installed water tube boiler of the present invention through specific examples.

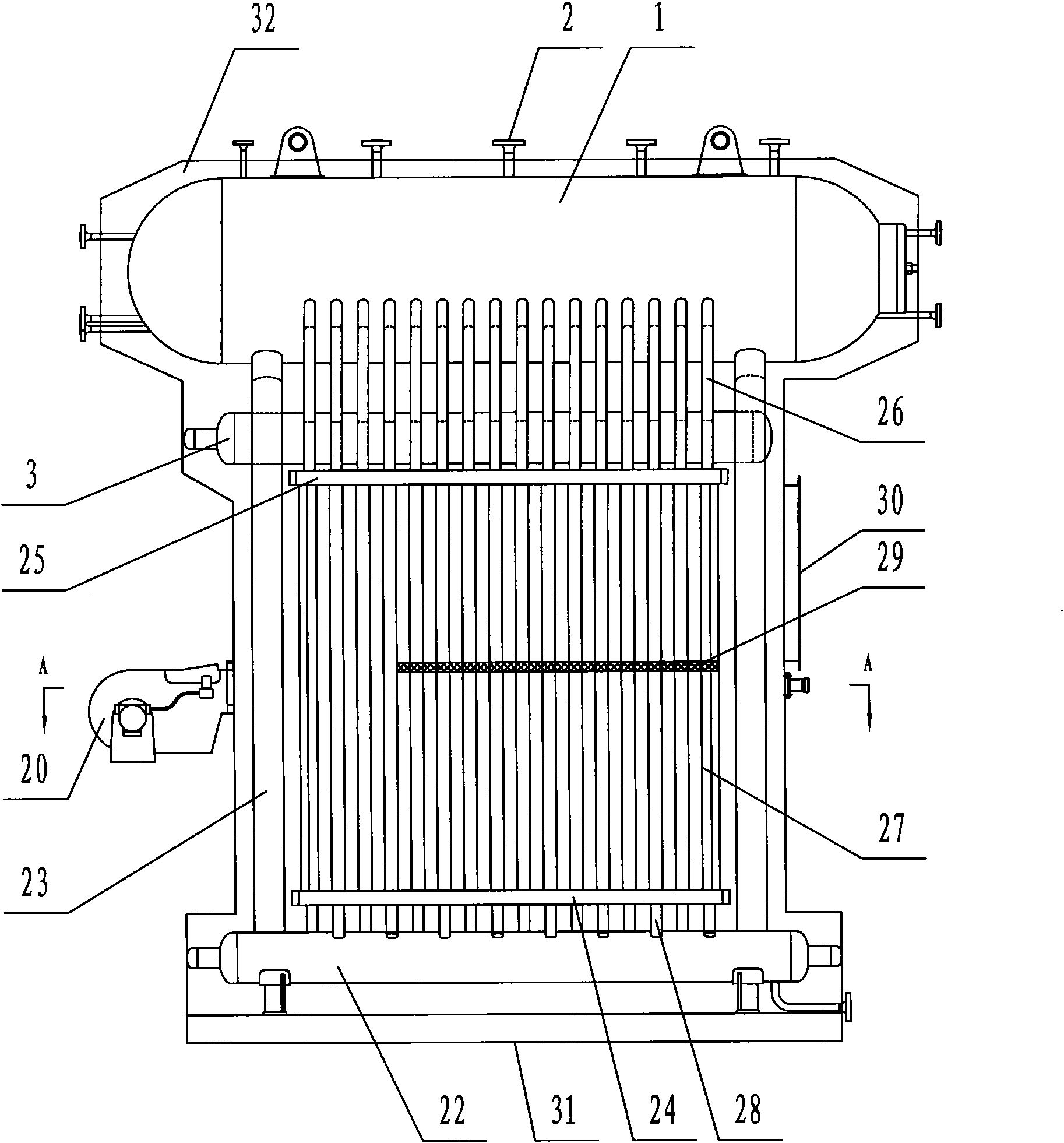

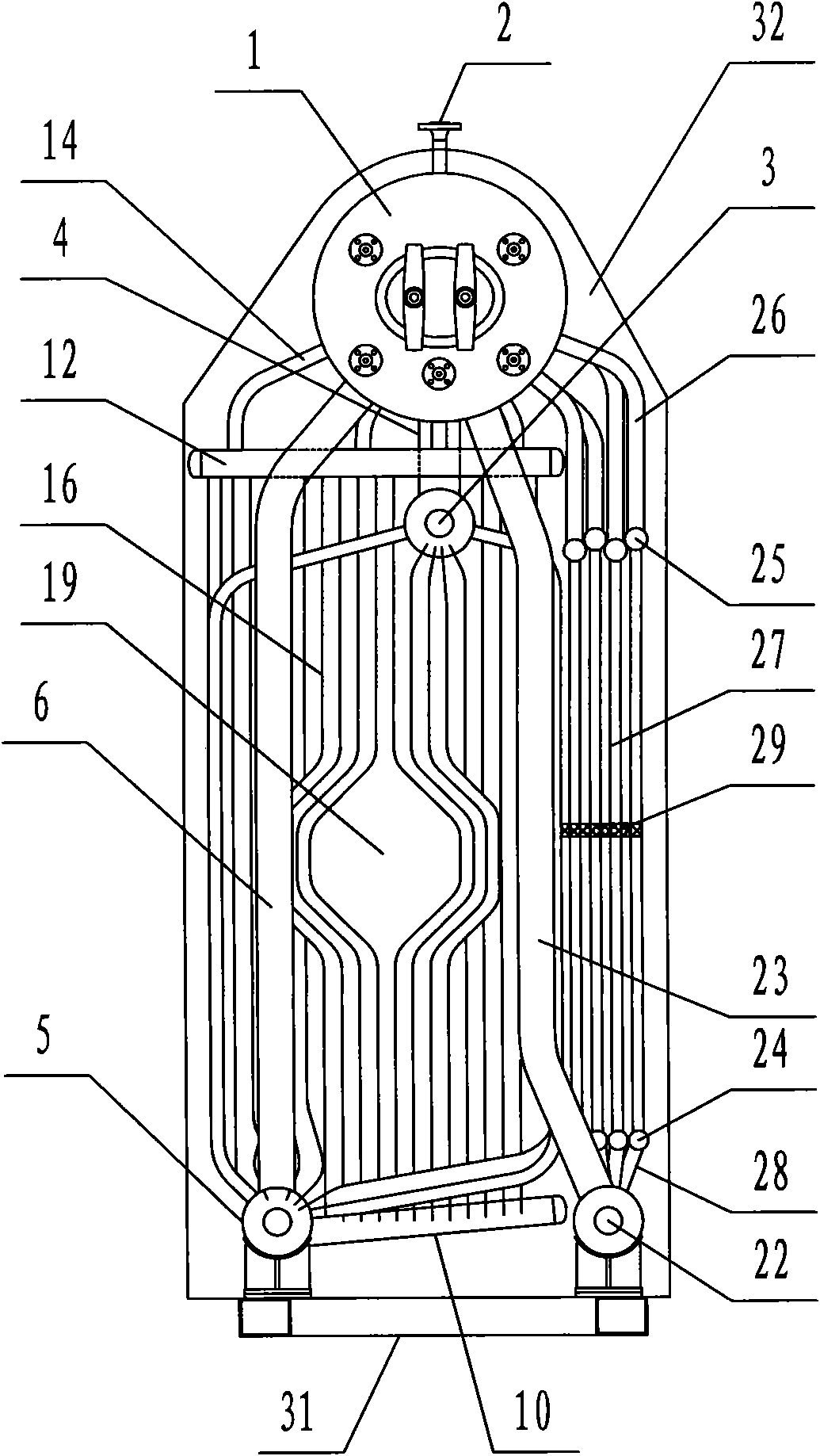

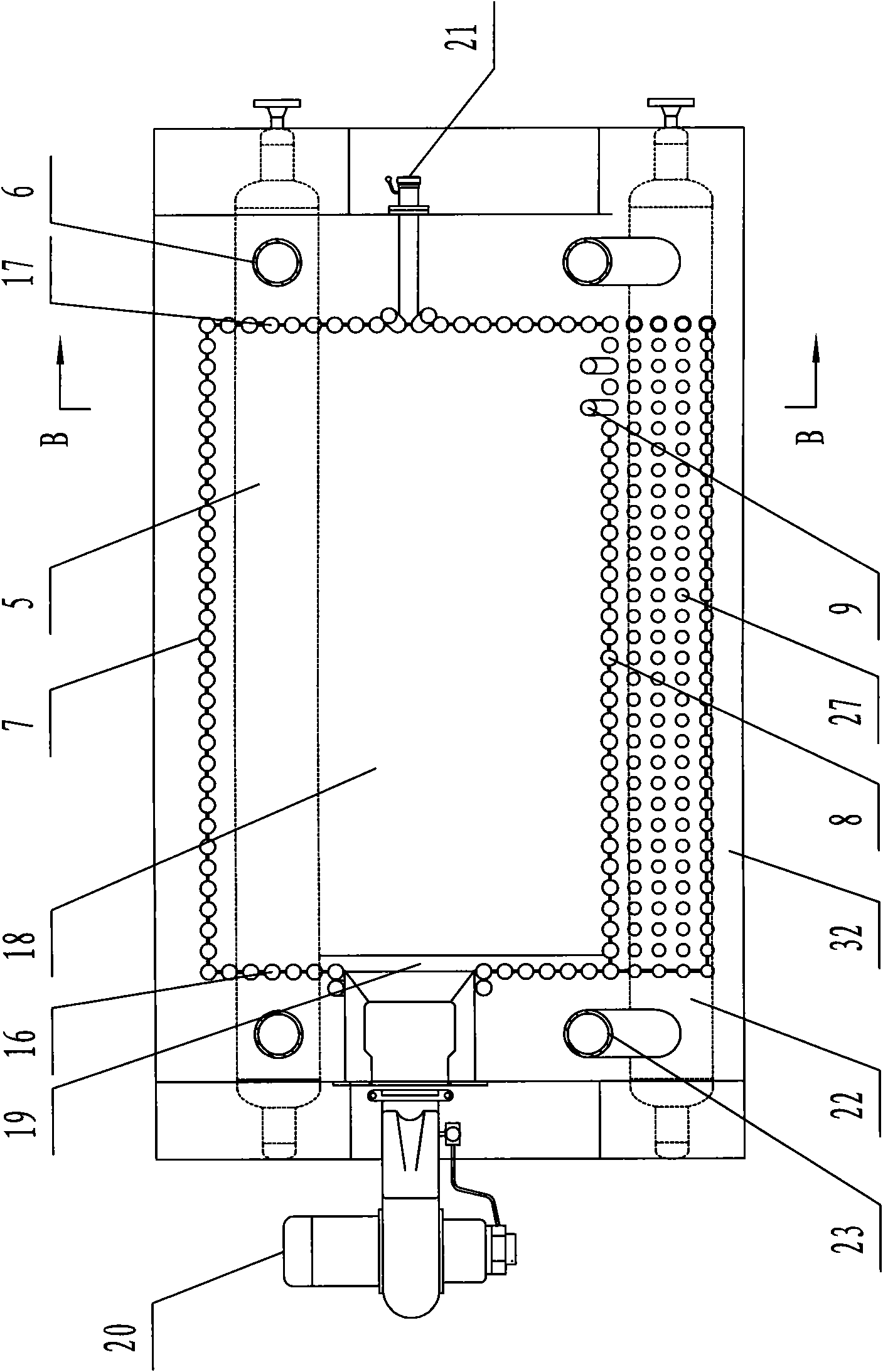

[0025] Such as figure 1 , figure 2 As shown, the fast-installed water tube boiler with a medium and high pressure single drum structure includes a drum 1, a steam outlet 2 is provided on the top of the drum 1, and a water cooling device is provided at the bottom of the drum 1, and the water cooling device includes an upper header 3 , the upper header 3 communicates with the drum 1 through the riser 4, and the lower header 3 is provided with a lower header 5, such as image 3 As shown, the lower header 5 communicates with the drum 1 through two lower header downpipes 6, and the two lower header downpipes 6 are located at both ends of the lower header 5 respectively, and the upper header 3 and the lower header The headers 5 are connected to each other through the water cooling wall ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com