Control system of carbon intensity distribution of low-pressure carburized layer and control method thereof

A low-pressure carburizing and distribution control technology, which is applied in the direction of comprehensive factory control, comprehensive factory control, electrical program control, etc., can solve the problems that the concentration distribution, control, and boundary conditions of the carburized layer cannot be controlled correctly, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0065] The ICBD horizontal vacuum low-pressure pulse carburizing furnace from ECM Company is selected, with a power of 1000kW. Furnace loading capacity 500kg. Use C3H8 as carburizing gas. The throughput is 3800 liters / hour. The nitrogen flow rate is 1500 liters / hour. The maximum vacuum degree in the furnace is 10 -2 mbar. The pressure in the furnace during the carburizing stage is 300mbar. The pressure in the furnace during the diffusion stage is 70mbarmin.

[0066] Select DELL model industrial control machine.

[0067] Choose DRUCK / IFM / KELLER / Rosemount pressure sensor. The nitrogen regulating valve model is TYCO / BURKERT / COAX. The diameter of the nitrogen input pipe is 50mm. Carburizing gas input pipe diameter 25mm. The carburizing gas regulating valve model is VALPES. The vacuum pump model is BOC / RIETSCHLE.

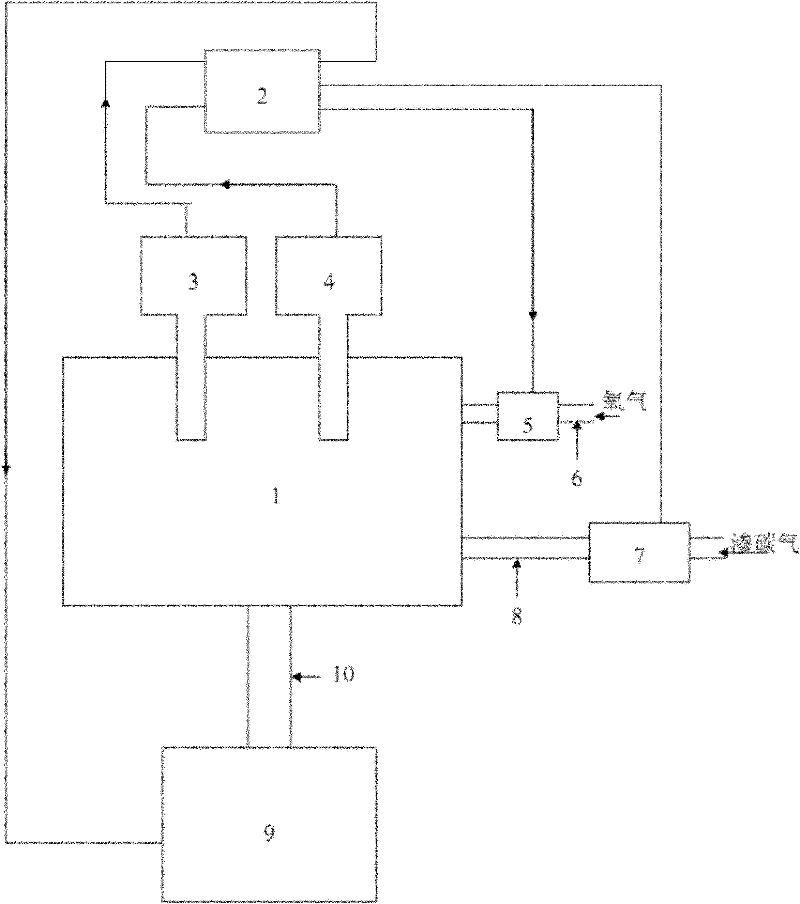

[0068] Attach the above equipment and devices to the figure 1 The way shown is linked to become a low pressure pulse carburizing layer concentration distrib...

Embodiment 3

[0076] The SJTUVLC-75 vacuum low-pressure pulse carburizing furnace developed by Shanghai Jiaotong University is selected, with a power of 75kW. The size of the charging area is 600mm×600mm×900mm, and the furnace loading capacity is 400kg. use C 2 h 2 for carburizing gas. Flux 750 l / h. The nitrogen flow rate is 1500 liters / hour. The maximum vacuum degree in the furnace is 10 -2 mbar. The pressure in the furnace during the carburizing stage is 150mbar. The pressure in the furnace during the diffusion stage is 75mbar.

[0077] Select Advantech IPC610 industrial control machine as the controller.

[0078] Choose DRUCK / IFM / KELLER / Rosemount pressure sensor. The nitrogen regulating valve model is TYCO / BURKERT / COAX. The diameter of the nitrogen input pipe is 30mm. Carburizing gas input pipe diameter 20mm. The carburizing gas regulating valve model is VALPES. The vacuum pump model is BOC / RIETSCHLE.

[0079] Attach the above equipment and devices to the figure 1 The way ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com