Method for stimulating fluid-solid-heat coupling value of machine tool spindle

A technology of machine tool spindles and simulation methods, applied in the direction of electrical digital data processing, special data processing applications, instruments, etc., can solve the problems that the deformation of the spindle has a large influence, and the influence of the spindle bracket is not considered, so as to avoid low efficiency, accurate simulation results, Numerically simulated precise effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

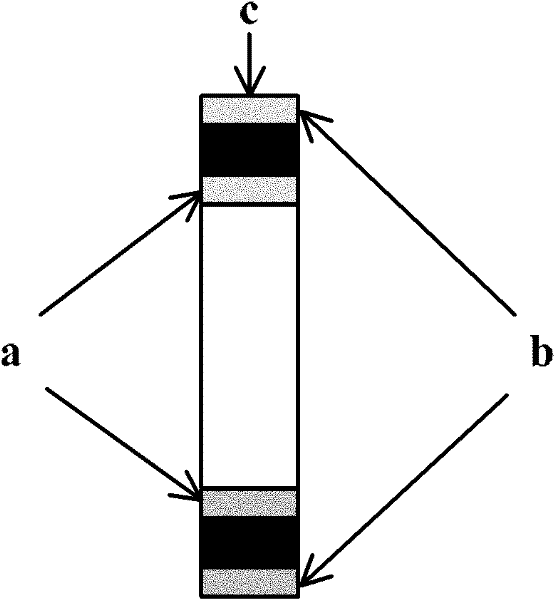

[0052] 1. Geometric modeling

[0053] 11 Use the geometric modeling software Pro / E to simplify the original ram model as necessary:

[0054] (1) Delete steps smaller than 1mm;

[0055] (2) Delete the threaded hole;

[0056] (3) Delete the feed motor and synchronous belt part at the rear end of the ram;

[0057] (4) Delete the broach mechanism;

[0058](5) Retain the thin steel plate on the rear tailpiece;

[0059] (6) The simplified model of the ram seat is retained, and only its ribs and contact points with the ram are retained in the model of the ram seat, and all other details are simplified.

[0060] 1.2 Use Pro / E software to establish the geometric model of the coolant according to the size of the coolant flow channel on the basis of the original ram model.

[0061] 1.3 Use Pro / E software to replace the bearing in the ram with a ring of the same size as the bearing.

[0062] 2. Calculate the temperature field and analyze the boundary conditions

[0063] For the cal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com