Simulating device of leakage-stopping training of damaged pipes on ship

A simulation device and pipe plugging technology, which is applied in the field of simulation, can solve the problems of not meeting the training needs of ship damaged pipe plugging, and the device cannot be simulated, and achieve the effect of simple structure, realistic swing, economical and practical

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

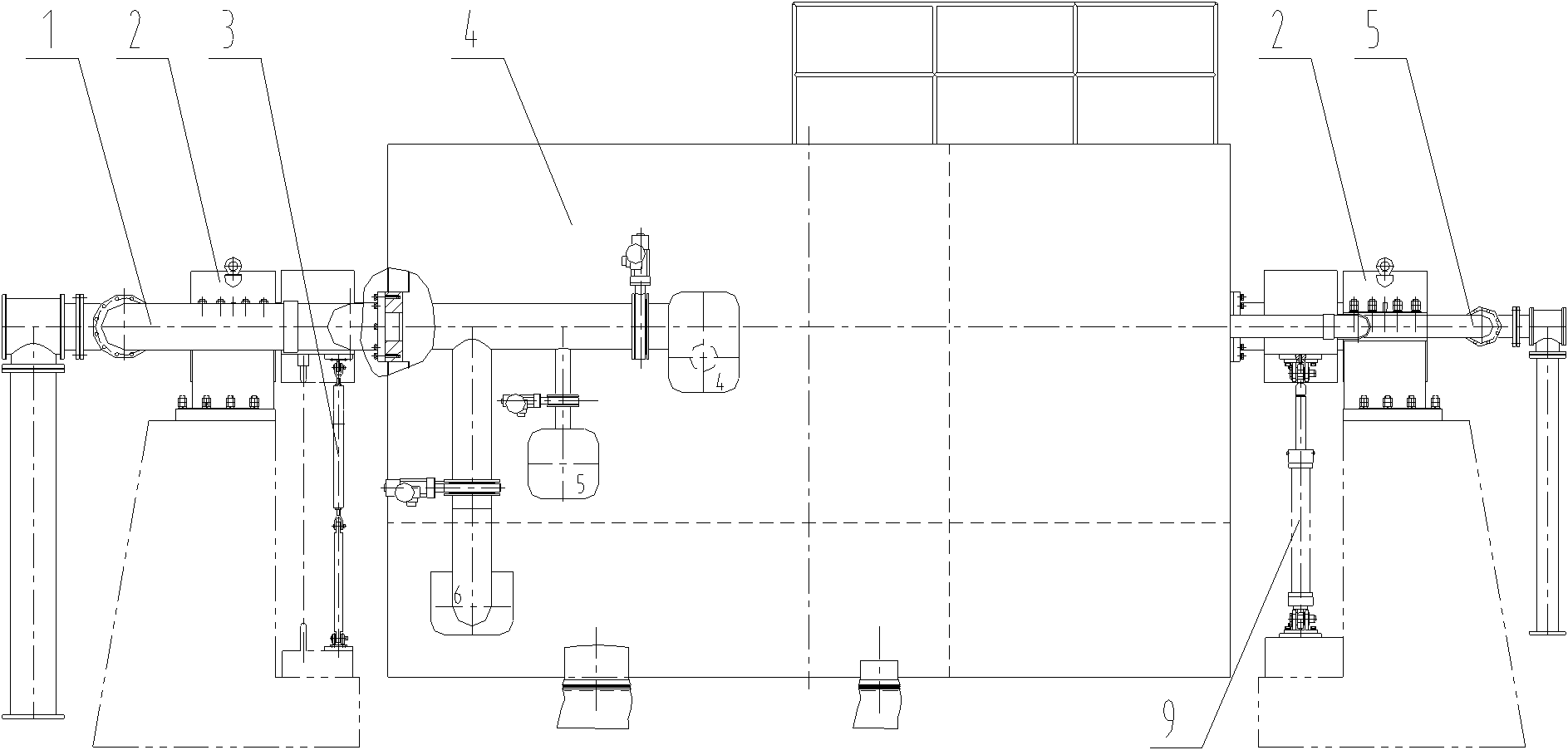

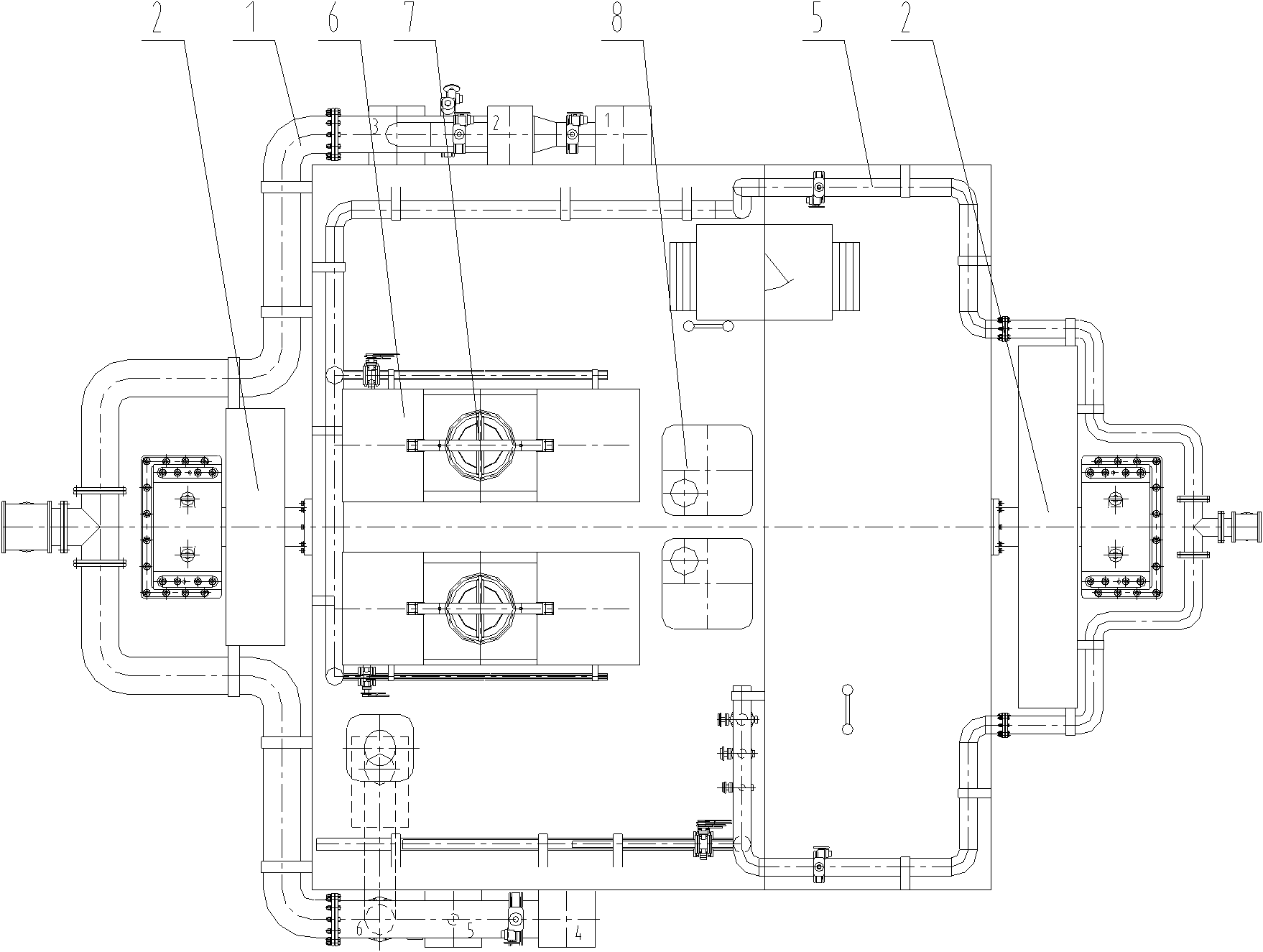

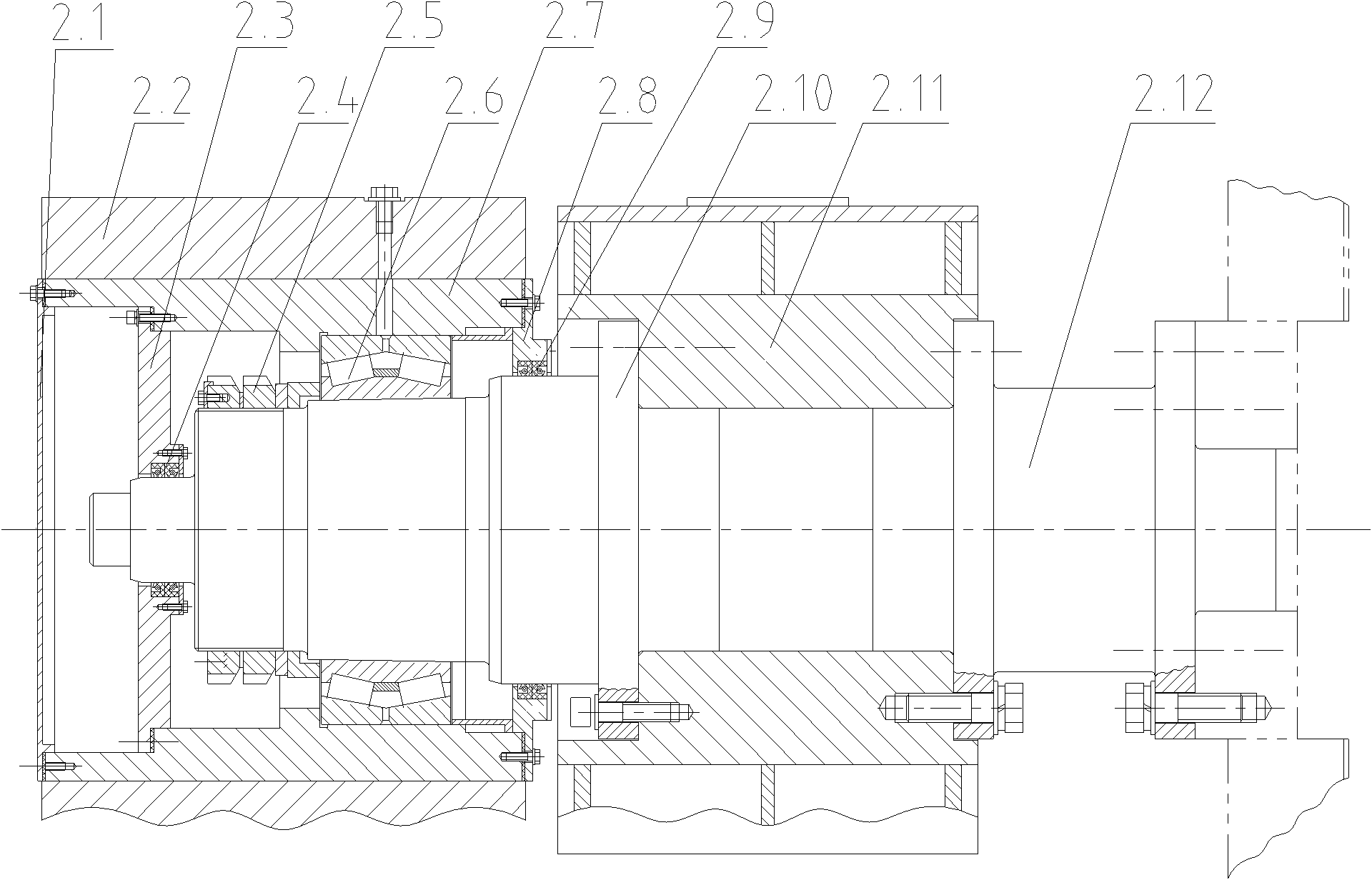

[0026] A ship damaged pipe plugging training simulation device, including two parts, a mechanical platform body and a hydraulic drive mechanism; the mechanical platform body is composed of a simulated cabin, a shafting 2, and a locking mechanism 3, and the simulated cabin is composed of a cabin body 4, a breach plugging mechanism Pipe group 1, damaged pipe plugging pipe group 5, simulation equipment 6, water level adjustment mechanism 7 and floor drain 8, the simulated cabin is supported by two half-shafts 2.10, and both ends of the two half-shafts 2.10 use self-aligning roller bearings 2.6, The bearing at one end of the shaft adopts fixed support, and there is clearance at the other end. A sensor 2.14 is installed at the end of the shaft, and a sealing cover 2.1 is arranged on the outside. The shaft system 2 is composed of a driving bracket 2.13, a locking bracket 2.11, a half shaft 2.10 and a bearing housing 2.2, and the driving bracket 2.13 and the semi shaft 2.10 are assem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com