Dual frequency conversion control system

A control system and double frequency conversion technology, applied in the field of frequency conversion control, can solve the problems of low power utilization, high power consumption of AC motors, low motor stability, etc., and achieve the goal of reducing resource consumption, high power utilization and high stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

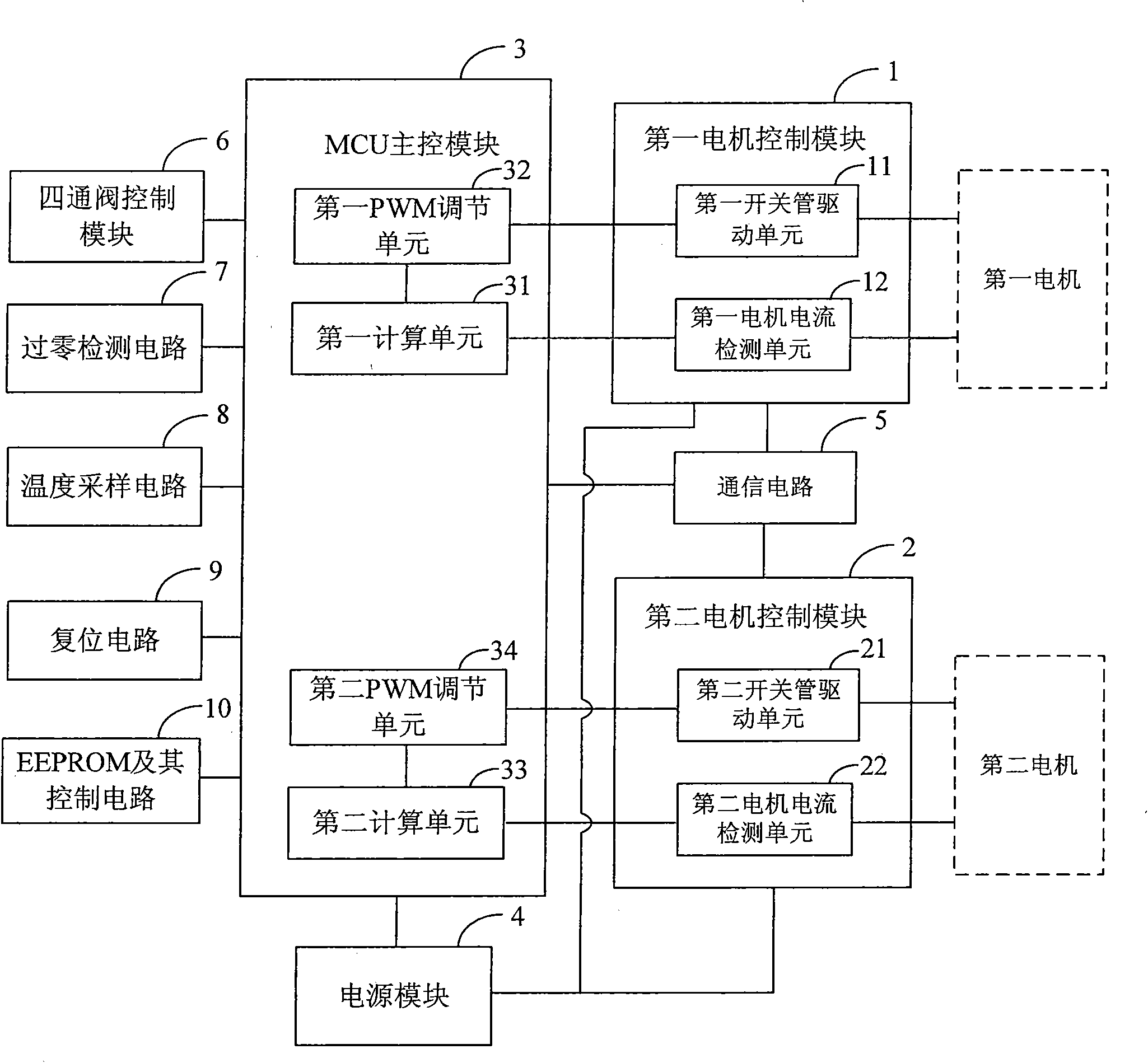

[0042] Such as figure 1 Shown is a schematic structural diagram of the double conversion control system of the present invention. In the present invention, the application of the dual frequency conversion control system to air-conditioning control is mainly used as an example for elaboration. The dual frequency conversion control system includes: a first motor control module 1, a second motor control module 2, an MCU main control module 3, and a power supply module 4 , communication circuit 5, four-way valve control module 6, zero-crossing detection circuit 7, temperature sampling circuit 8, reset circuit 9, EEPROM and its control circuit 10.

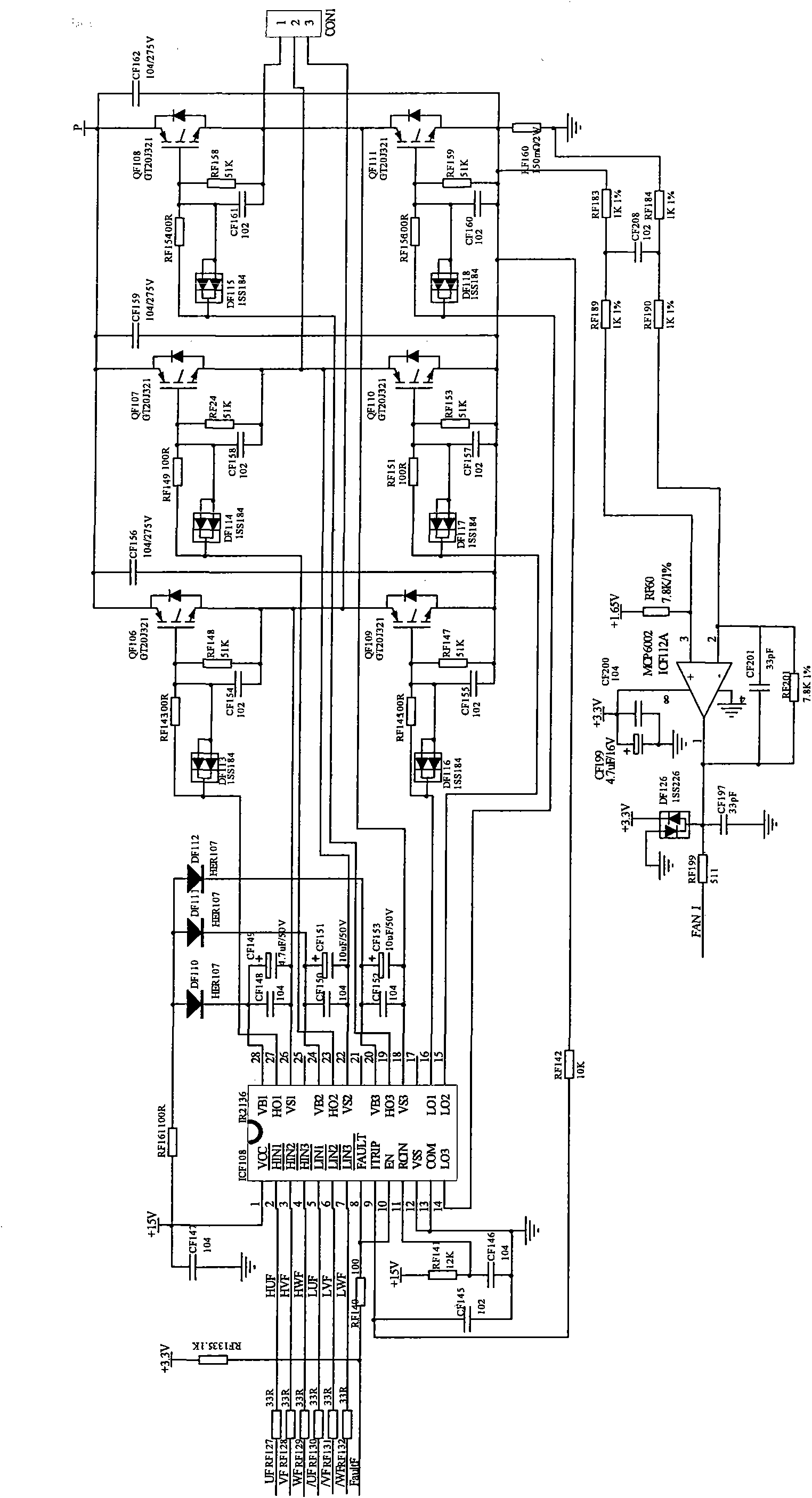

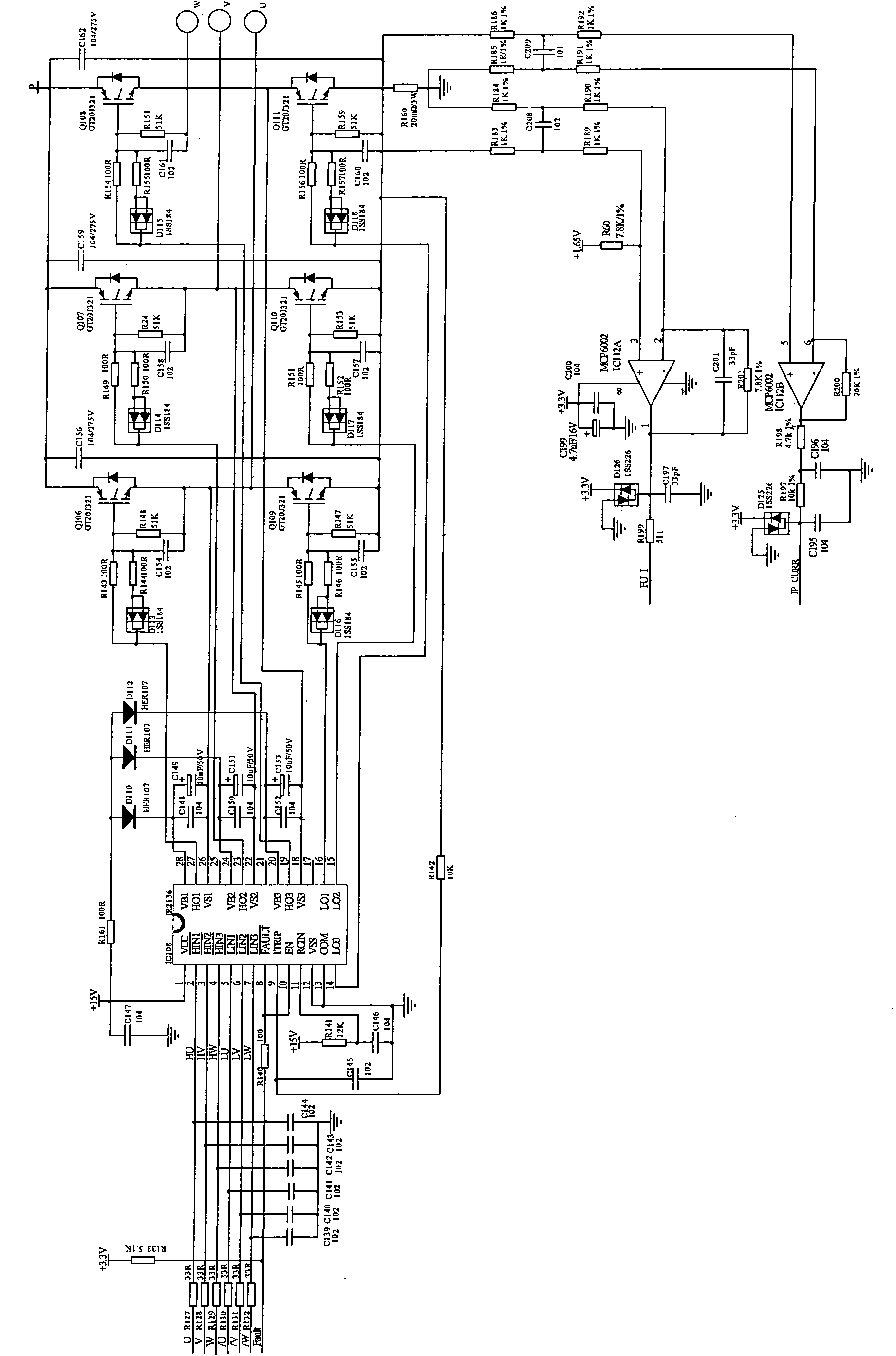

[0043] The first motor control module 1 is used to control the working state of the first motor controlled by 180-degree DC frequency conversion. The second motor control module 2 is used to control the working state of the second motor controlled by 180-degree DC frequency conversion. The MCU main control module 3 generates the first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com