Laser cutting system for plates and cutting processing method thereof

A laser cutting and sheet metal technology, applied in laser welding equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of high precision requirements for position control components, affecting cutting effect, and high production cost, achieving fast processing speed and finished products. The effect of high rate and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

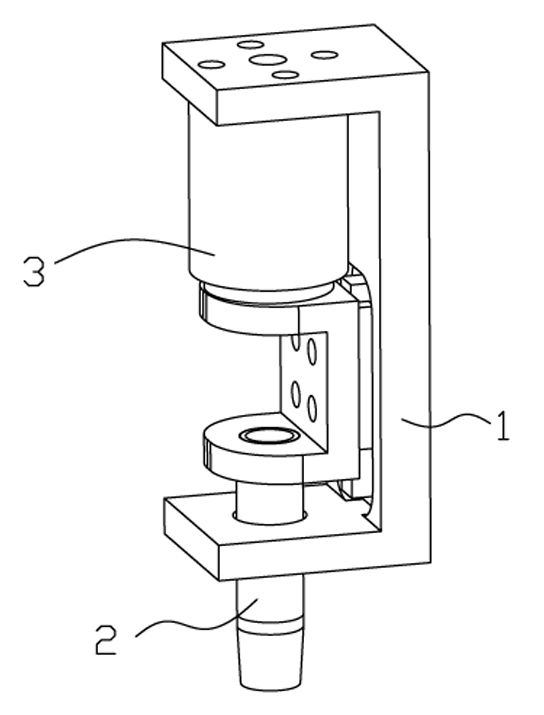

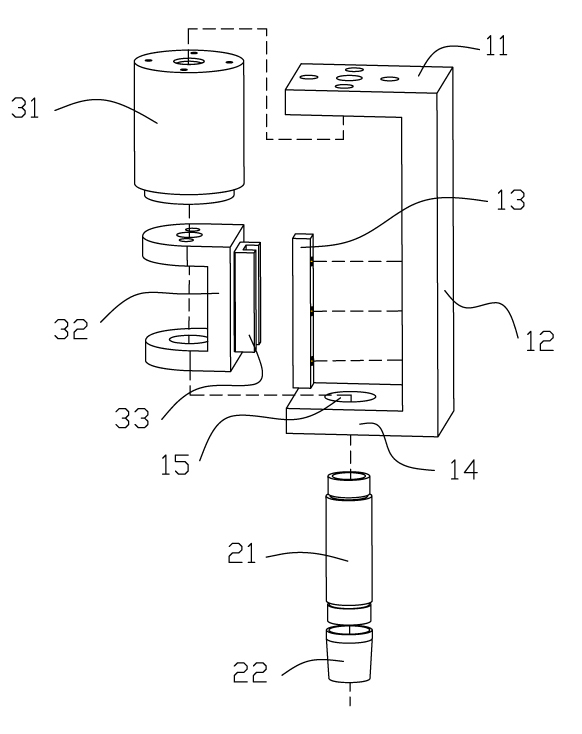

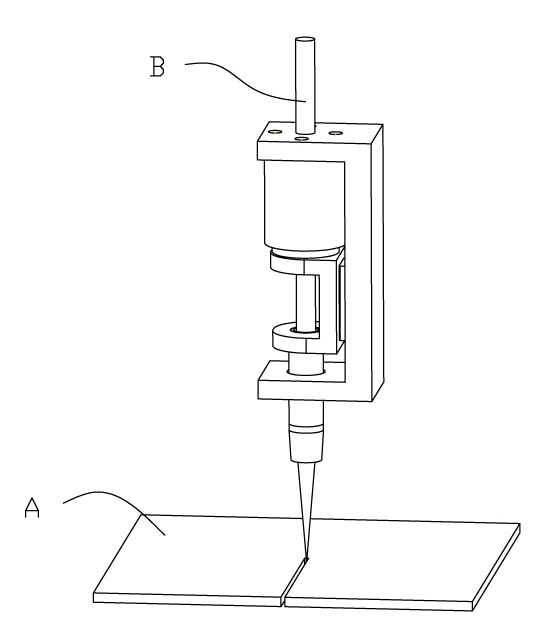

[0019] refer to figure 1 and figure 2 , a plate laser cutting system of the present invention includes a mounting seat 1, a laser focusing component 2 and a high-speed lifting driving device 3, the high-speed lifting driving device 3 is fixedly installed on the mounting seat 1, and the movable lifting driving device of the high-speed lifting driving device 3 is driven. The end is fixedly connected with the laser focusing component 2 . The present invention is installed on the cutting machine through the mounting seat 1, the mounting seat 1 can play the role of support and limit, the laser generated by other systems of the cutting machine is transmitted to the system, and then the control system of the cutting machine controls the high-speed lift drive device 3 Action, and constantly change the focus position of the laser, so that the plate can be completely cut through, so as to achieve one-time cutting of the plate.

[0020] The structures of the mounting seat 1, the high-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com