Welding clamp for assembling floor and battery box and manufacturing method

A technology for welding fixtures and battery boxes, which is applied to auxiliary devices, manufacturing tools, welding equipment, etc., can solve problems such as inaccurate structure of mounting holes, interference, and misalignment of two longitudinal beams before and after, so as to ensure efficiency and effect , Simplify cumbersome steps and improve welding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

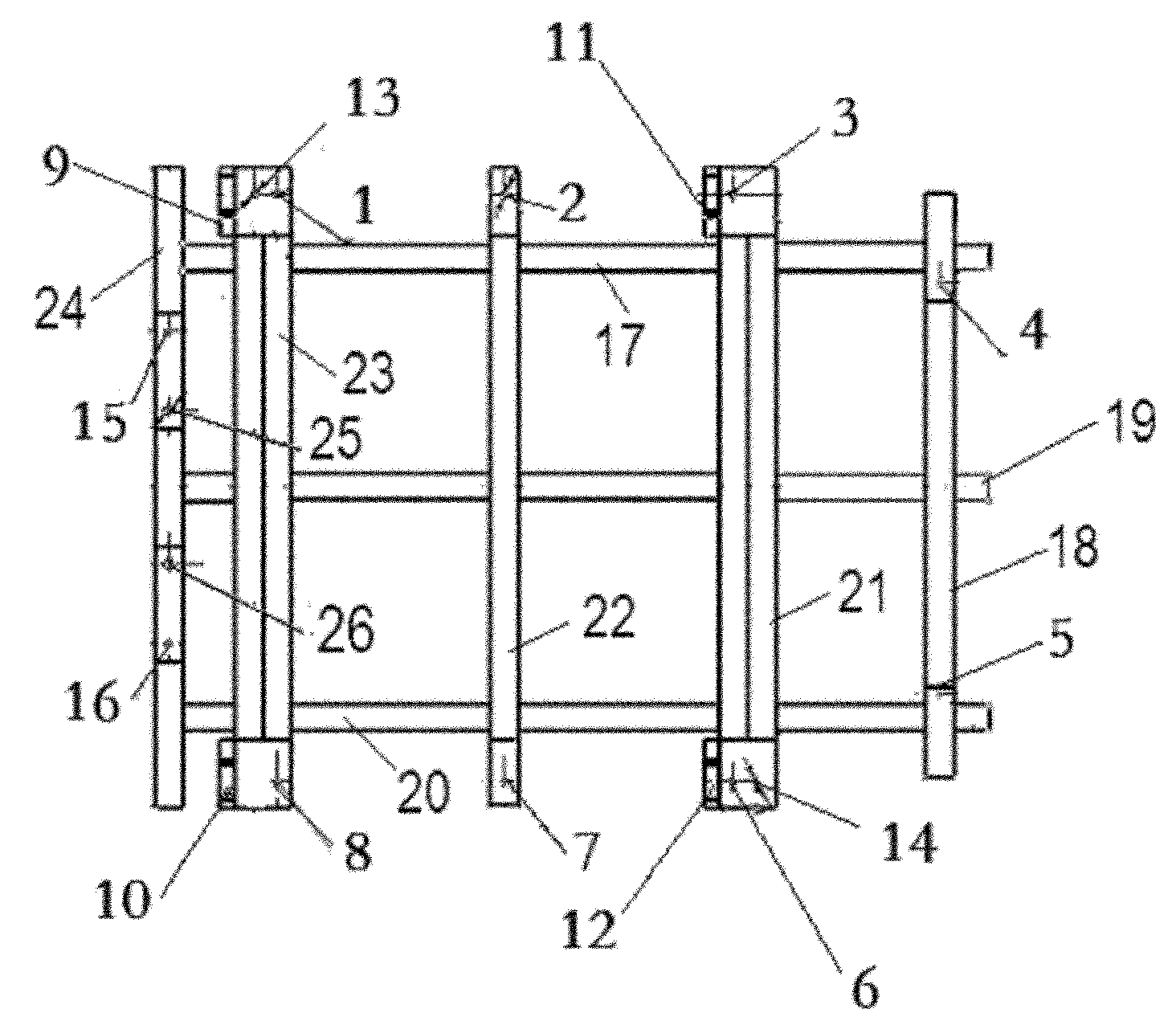

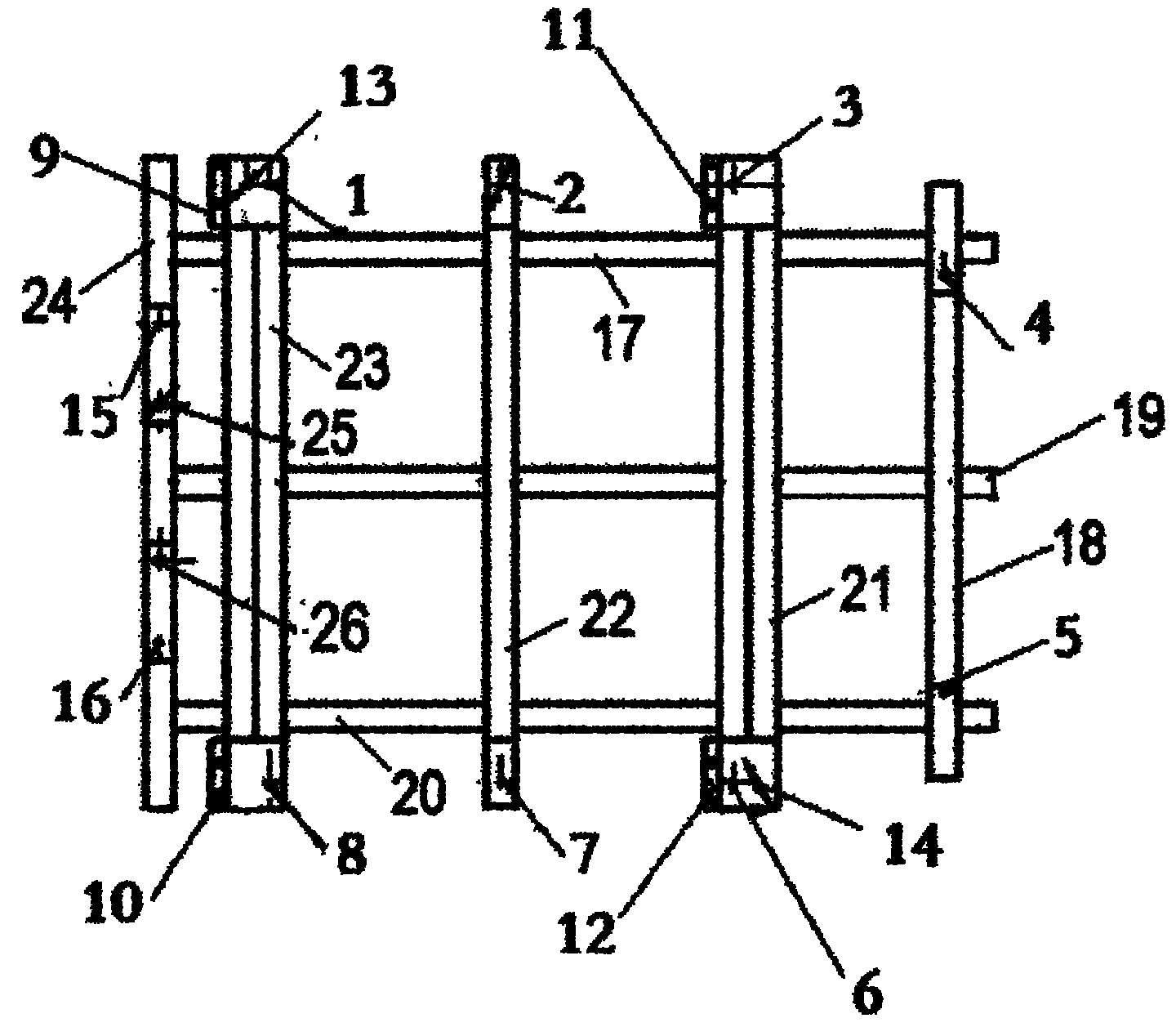

[0021] A method for manufacturing a welding jig for assembling a floor and a battery box,

[0022] It includes the following steps: first, weld a frame with a 40*60 rectangular tube, and the frame is basically the same as the position and size of the overall body floor stringer;

[0023] Weld a 10-20mm thick plate at the corresponding position of the battery box installation hole on the longitudinal beam;

[0024] Then cut four cross-section profiling positioning blocks according to the cross-sectional view of the external dimensions of the longitudinal beam; (as shown in the positioning block part)

[0025] Then, the welded skeleton is milled by CNC milling, and the surface of several welded thick plates is milled and drilled, so that the surface is on the same plane as the lower plane of the longitudinal beam, and the holes are opposite to the mounting holes of the battery box. The size is the same; (as shown in the picture)

[0026] Finally, weld the four cross-section pr...

Embodiment 2

[0029] A method for manufacturing a welding jig for assembling a floor and a battery box,

[0030] It includes the following steps: First, weld a skeleton with a 40*60 rectangular tube, the skeleton and the overall body floor longitudinal beam position and size are basically the same (the position and size of the body floor longitudinal beam depends on a certain model)

[0031] Weld a 10-20mm thick plate at the corresponding position of the battery box installation hole on the longitudinal beam; (as shown in the figure, the box part corresponding to the sub-hole position is the welding area of the thick plate)

[0032] Then cut four section profiling positioning blocks according to the cross-sectional view of the external dimensions of the longitudinal beam; (the positioning block part in the figure)

[0033] Then, the welded skeleton is milled by CNC milling, and the surface of several welded thick plates is milled and drilled, so that the surface is on the same plane as th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com