Integrated grinding/turning mechanism of grinding lathe for ball valve bodies

A ball valve body and turning and grinding technology, which is applied in the field of turning and grinding machines, can solve problems such as low work efficiency and affect the processing accuracy and quality of ball valve bodies, and achieve the effect of improving work efficiency and improving surface grinding precision and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

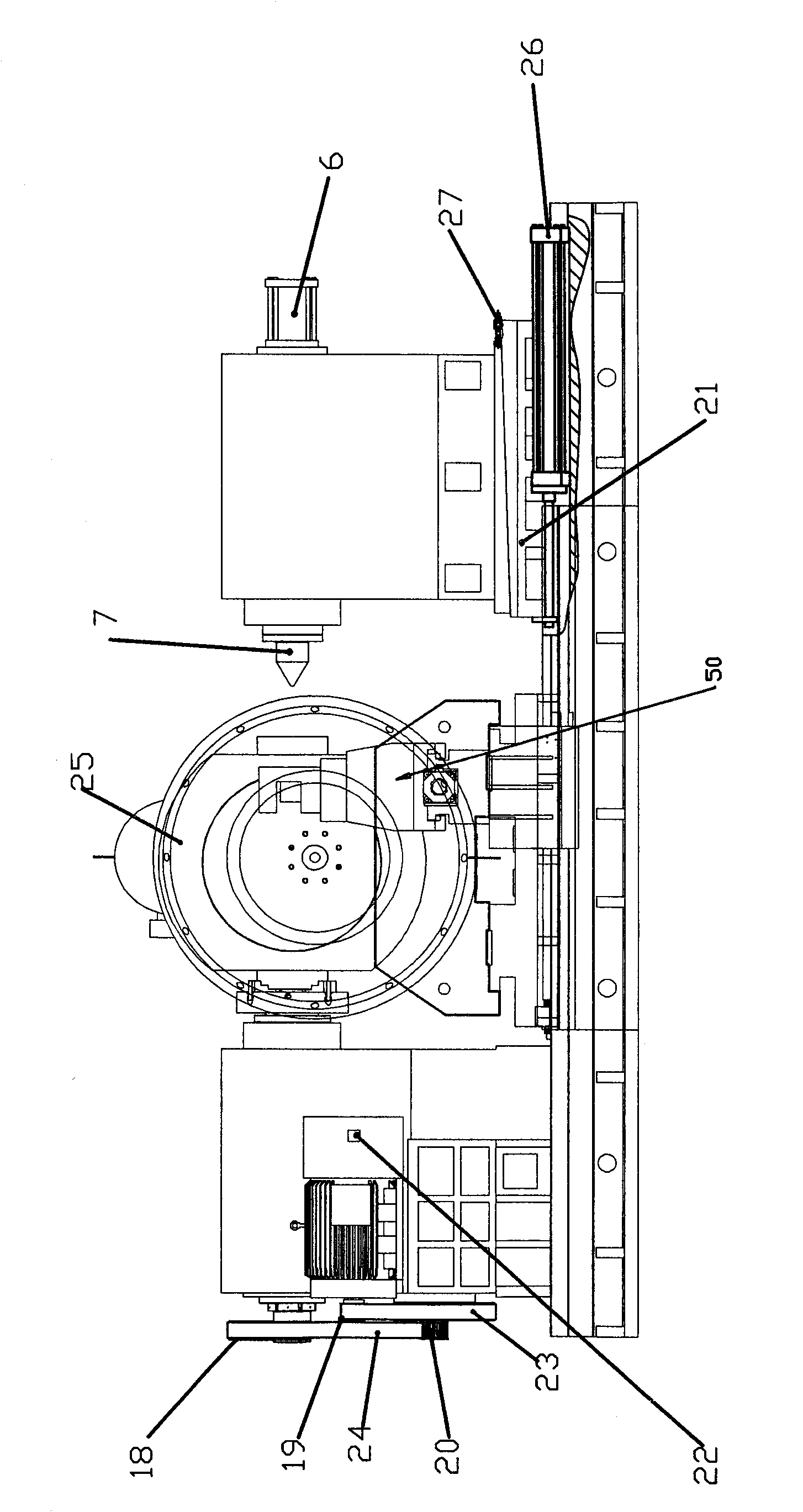

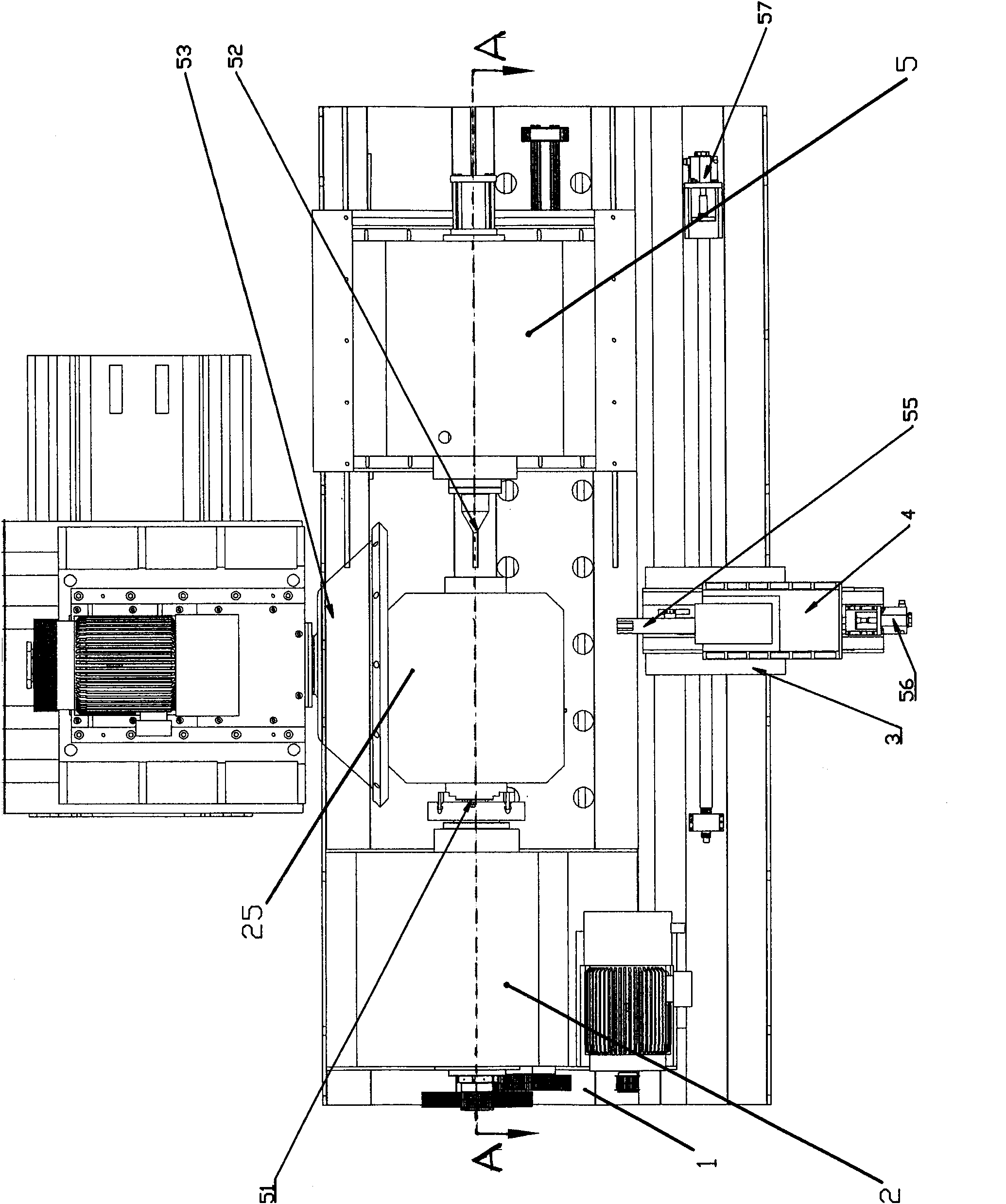

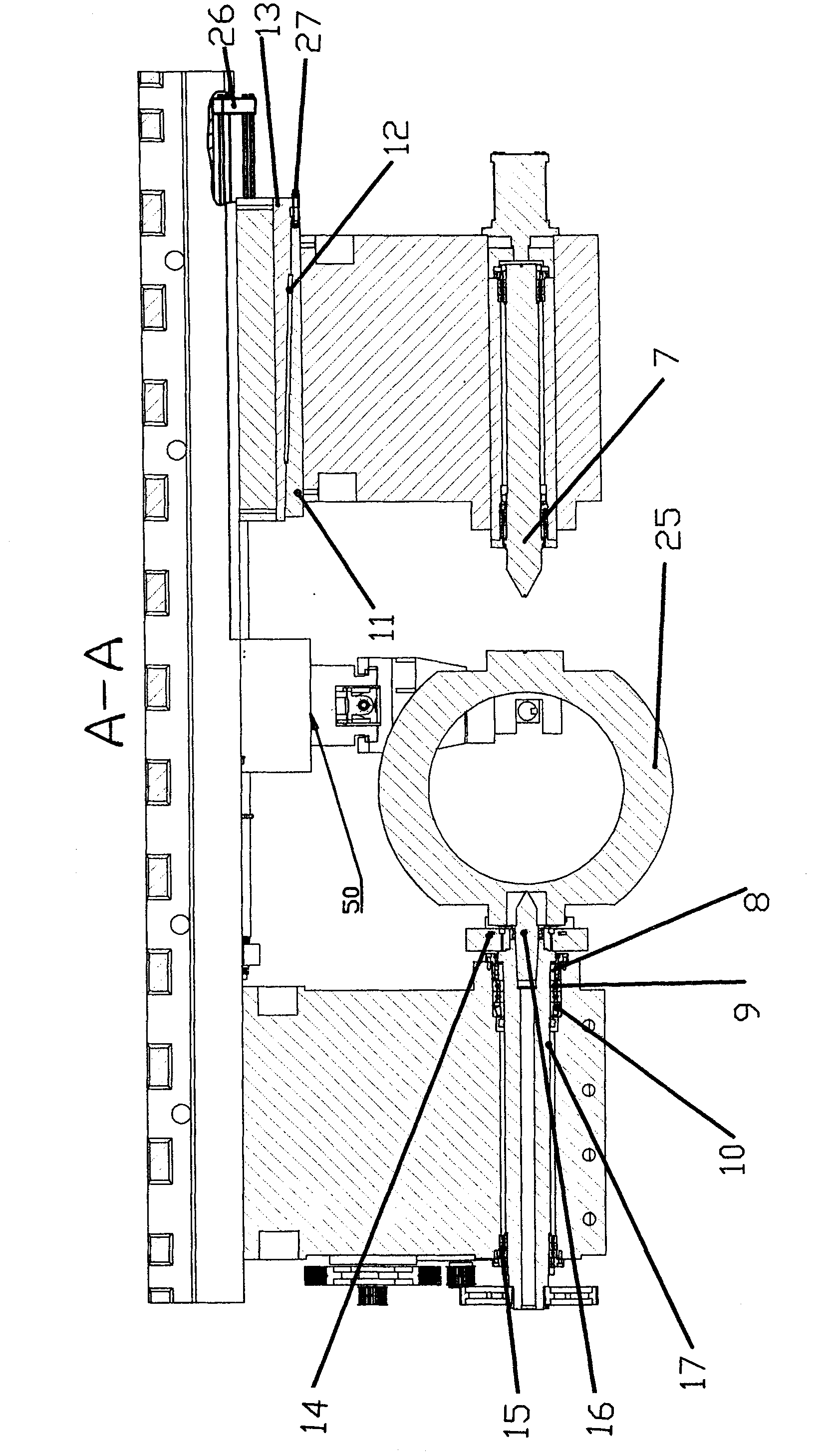

[0011] refer to Figure 1 to Figure 3 It can be seen that the integrated turning and grinding mechanism of the ball valve body turning and grinding machine of the present invention includes a bed base 1, a ball clamping device 51, a ball jacking device 52, and a grinding disc rotation control device 53 (installed at the side of the bed base). On the described bed base 1, a turning device 50 is installed at the opposite side of the grinding disc rotation control device 53 and the side of the ball clamping device 51 (with the ball jacking device 52); the turning device 50 It is composed of a car ball saddle 3, a car ball skateboard 4, a car head assembly 55, a slide plate longitudinal movement control assembly 56 and a saddle lateral movement control assembly 57.

[0012] Wherein, the car ball skateboard 4 is contained on the car ball slide saddle 3, the head assembly 55 is contained on the head of the car ball skateboard 4, and the skateboard longitudinal movement control assem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com