Turntable-type pad printer with double printing heads

A technology of rotary disc printing machine, applied in transfer printing, rotary printing machine, printing machine, etc., can solve the problems of no introduction and storage of pattern information, less information stored in pad printing plate, labor-consuming and time-consuming problems, etc., to achieve pattern Intact and clear, convenient for centralized management, and the effect of printing a large amount of information

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings.

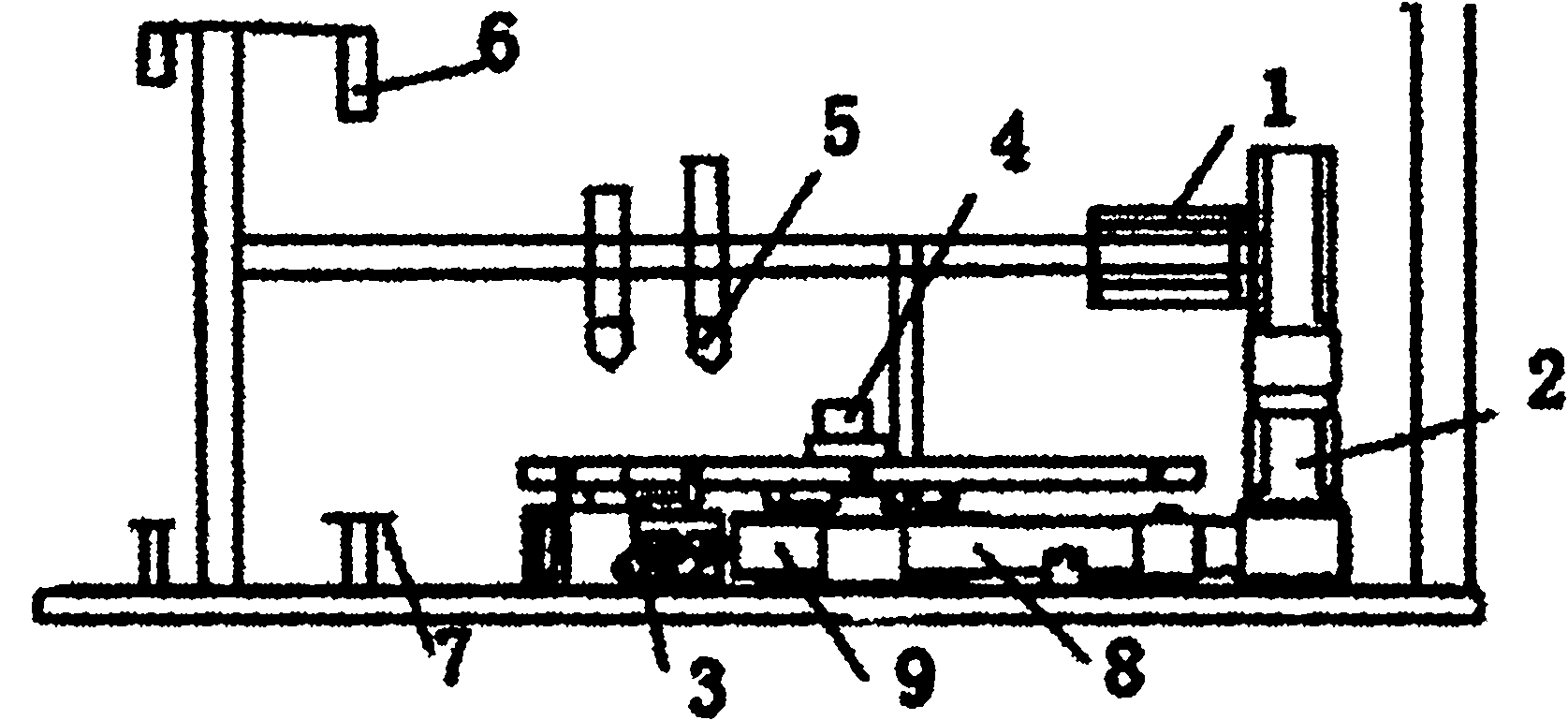

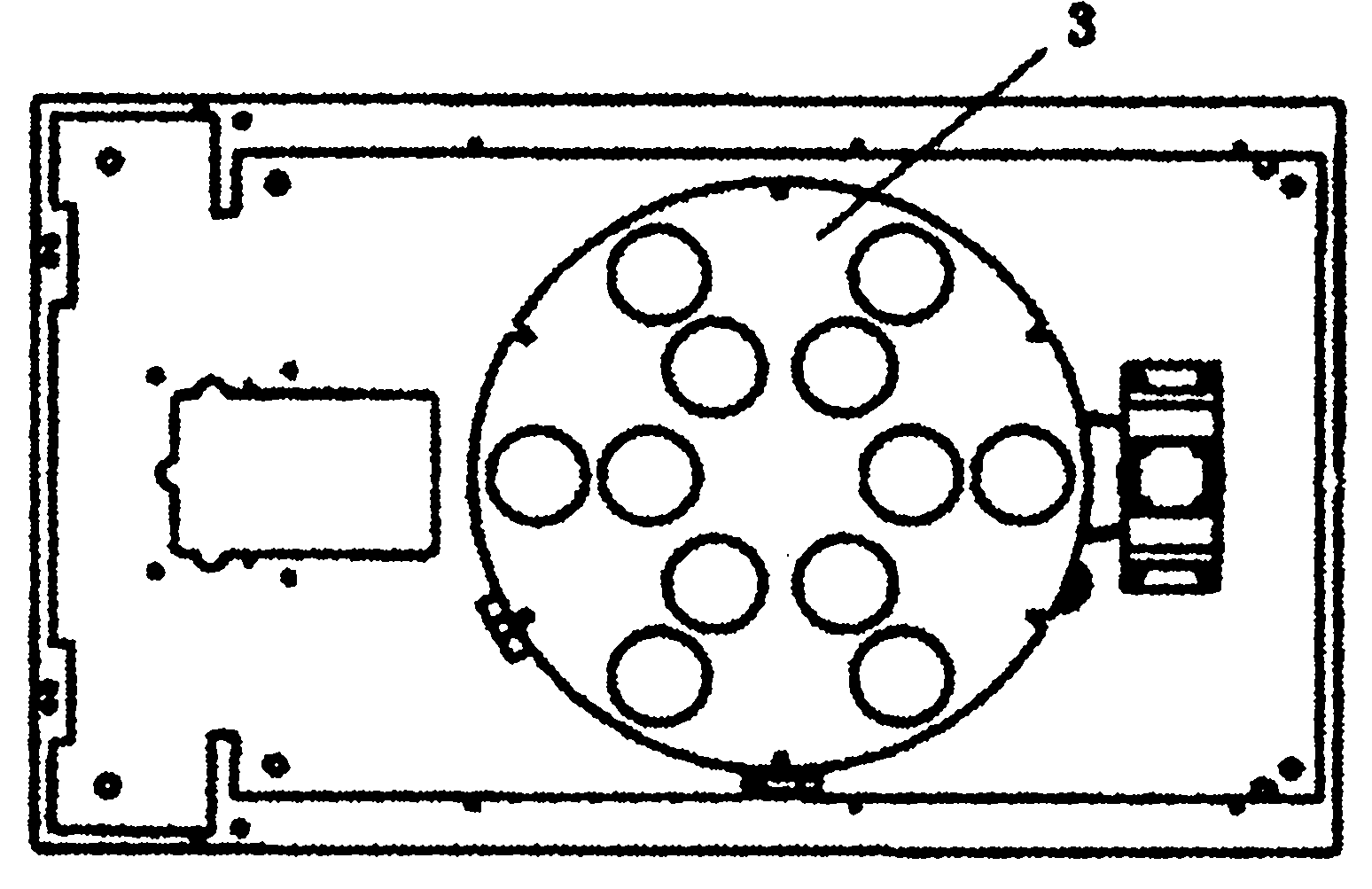

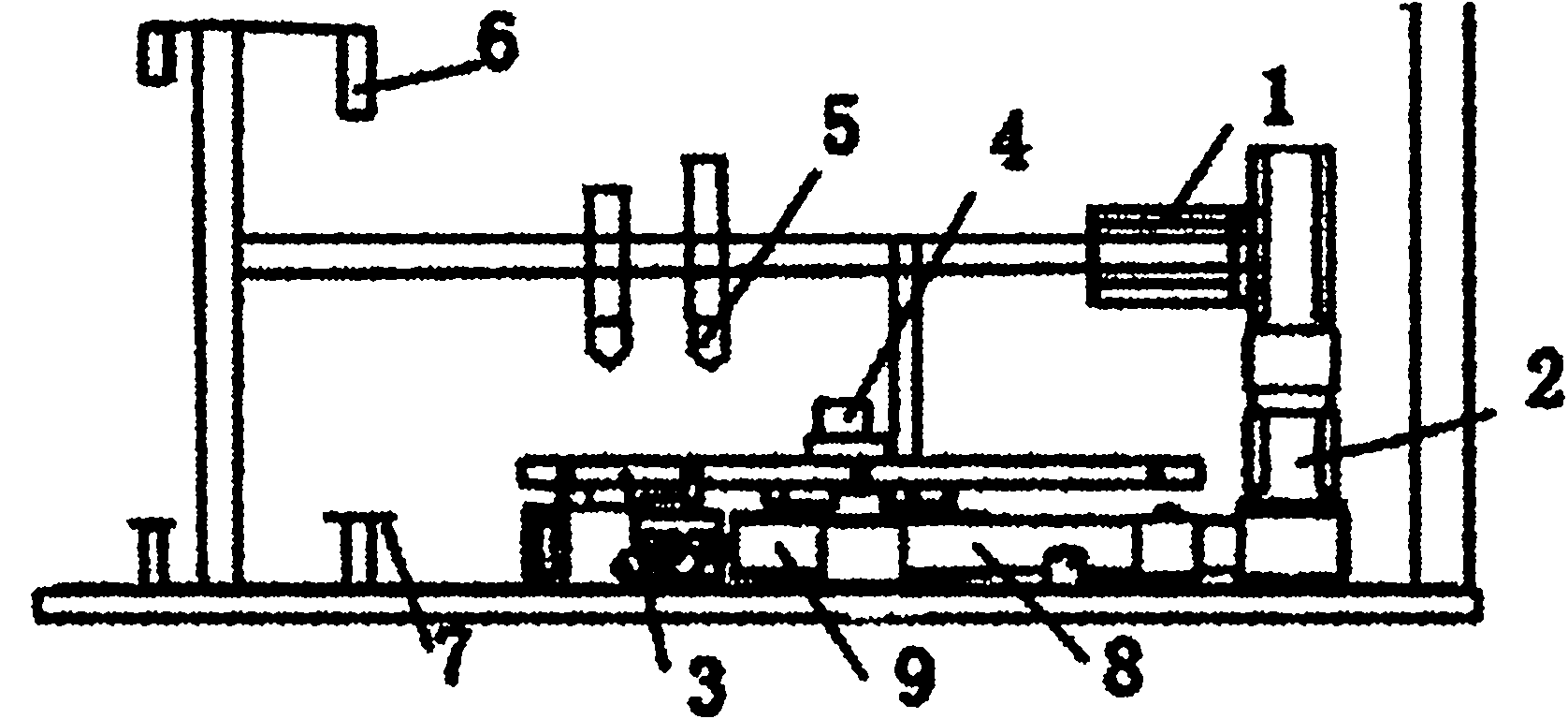

[0021] refer to figure 1 As shown, a turntable type double printing head pad printing machine includes a driving device, a position control device and a transmission device. Here, the driving device and the position control device can use the same servo motor 1 here, and the transmission device adopts a reducer 2, synchronous Belt 8 and synchronous pulley 9, the connection of each part is operated and connected by known technology. In the present invention, there are six groups of pad printing patterns evenly on the circumferential direction of the turntable pad printing plate 3 (that is, there is a group of patterns every 60 degrees), and each group of patterns has two patterns of L and R respectively. The six different angles correspond to six different patterns. The turntable pad 3 is connected to the servo motor 1, which drives the rotation angle of the turntable ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com