Method and device for separately taking out carton for packaging ceramic tiles

A technology for taking out a device and a carton, applied in packaging and other directions, can solve the problem of inability to take and send the carton normally, and achieve the effect of rapid separation of the carton

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

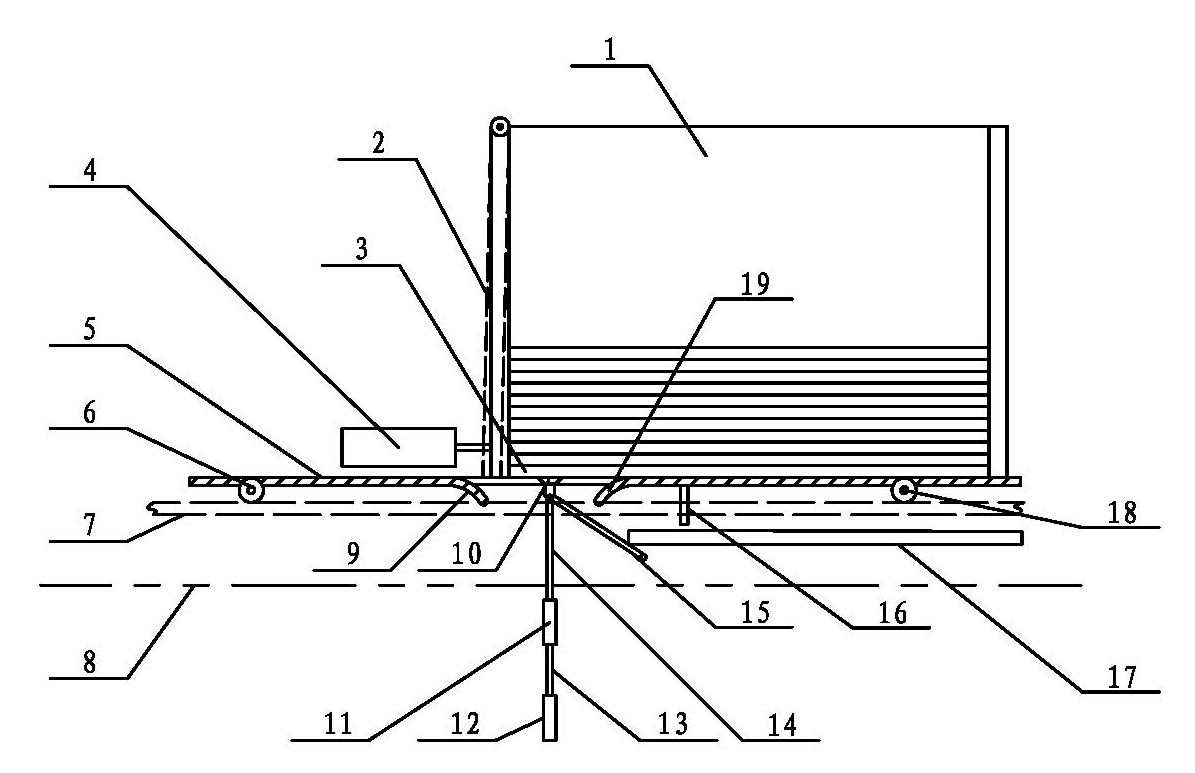

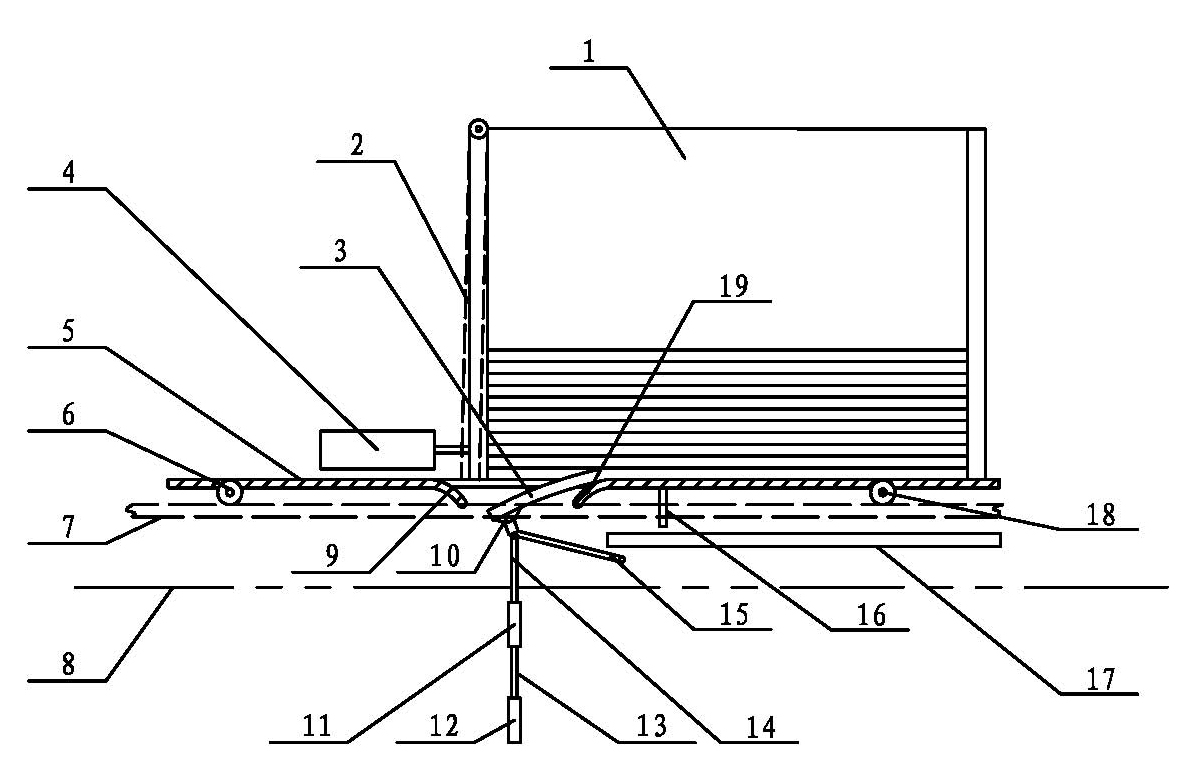

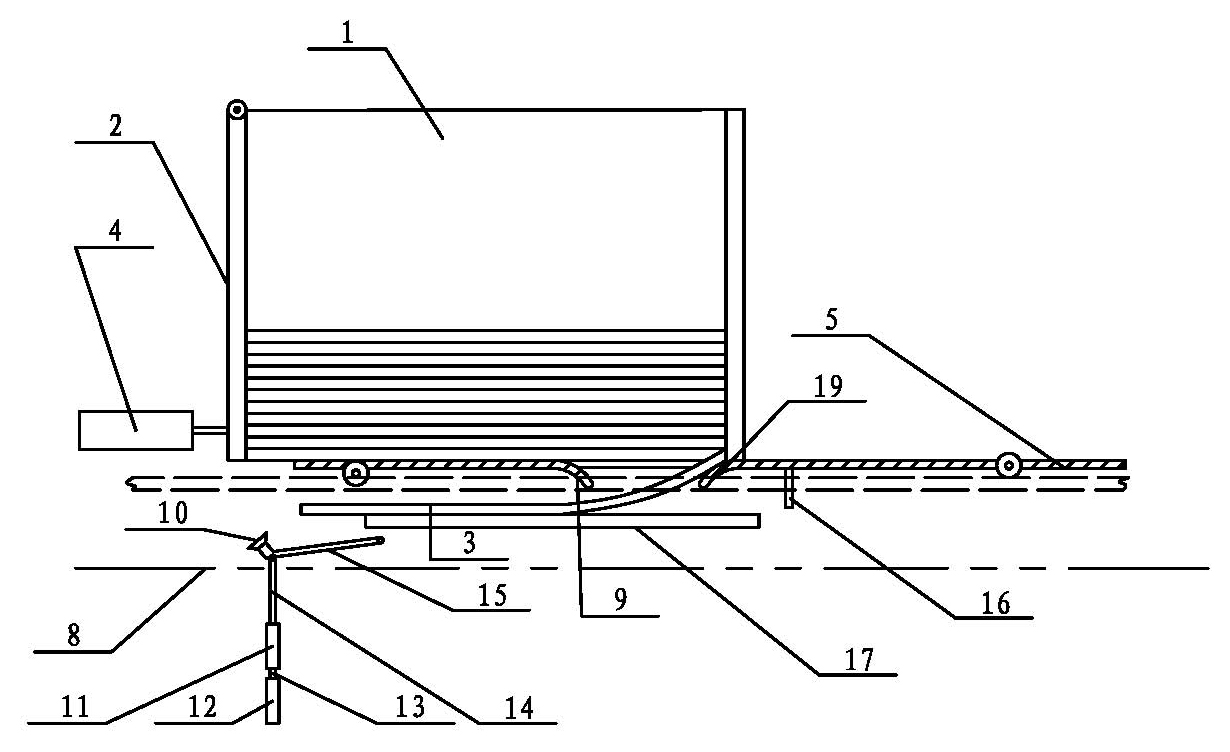

[0027] The method for separating and taking out cartons for packaging ceramic tiles described in the present invention is carried out sequentially as follows: stack the cartons in the carton storage bin 1, the bottom of the carton storage bin 1 is open, bend the front end of the lowermost carton downwards, and then place the cartons on the bottom A carton separator is inserted between the lower carton and the upper carton next to it, and the carton separator moves backward to separate the lowermost carton from the upper carton next to it, and the lowermost carton falls to complete a carton separation.

[0028] A carton outlet is provided in the middle of the carton separator, and the separated cartons fall through the carton outlet. The dropped cartons fall onto the carton tray, and then the carton divider moves forward in reverse to push the cartons on the carton tray forward to the carton conveyor belt.

[0029] According to the method for separating and taking out the above...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com