High heat resistance low density high performance auto polypropylene composite and preparation method thereof

A polypropylene composition and low-density technology, which is applied in the field of high-heat-resistant and low-density high-performance polypropylene composition and its preparation, can solve the problems of incompatibility of high heat resistance and high toughness, achieve excellent comprehensive performance, reduce Emissions, Density Reduction Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0065] Table 1 Formula content

[0066] components

Example 1

Comparative example 1

Comparative example 2

Comparative example 3

PP

84.5%

85%

84.5%

84.5%

POE

5%

5%

5%

5%

Al 2 o 3 whiskers

5%

5%

10%

-

coupling agent

0.5%

-

0.5%

0.5%

talcum powder

5%

5%

-

10%

[0067] Put the above raw materials into a high-speed mixer with a rotation speed of about 1000rpm and mix them according to the weight percentage, and then put them into a twin-screw extruder. Get granulated. Wherein the coupling agent used is the mixture of epoxy resin, hydrogenated butadiene and monoglyceride, 50% by weight of epoxy resin, 25% by weight of hydrogenated butadiene, and 25% by weight of monoglyceride.

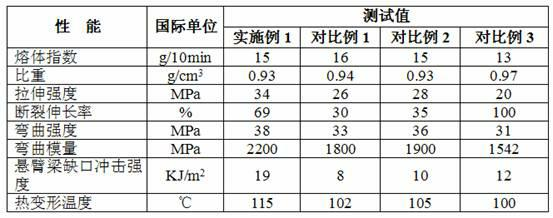

[0068] The properties of the prepared samples are as follows:

[0069] Table 2 Performance table

[0070]

[0071] Comparing Example 1 and Comparative Example 2 from Table 2...

Embodiment 2~ Embodiment 5

[0074] Table 3 Formula content

[0075] components

Example 2

Example 3

Example 4

Example 5

Comparative example 4

PP

64%

64%

65%

58%

58%

POE

15%

15%

10%

15%

10%

Al 2 o 3 whiskers

3%

10%

13%

15%

-

coupling agent

1%

1%

2%

2%

2%

talcum powder

17%

10%

10%

15%

30%

[0076] Put the above raw materials into a high-speed mixer with a rotation speed of about 1000rpm and mix for 3 minutes. See Example 1 for the extrusion granulation process. Wherein the coupling agent used is the mixture of epoxy resin, hydrogenated butadiene and monoglyceride, 30% by weight of epoxy resin, 40% by weight of hydrogenated butadiene, and 30% by weight of monoglyceride.

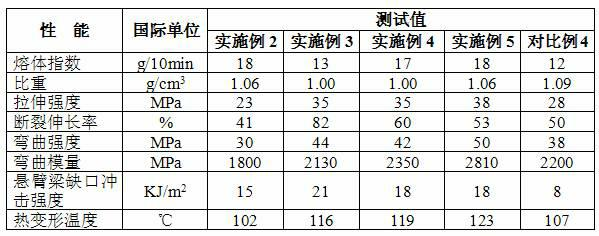

[0077] The properties of the prepared samples are as follows:

[0078] Table 4 Performance table

[0079]

[0080] Comparing Examples 2 to 5, it is found that the compounded talcum powde...

Embodiment 6~ Embodiment 9

[0082] Table 5 Formula content

[0083] components

Example 6

Example 7

Example 8

Example 9

PP

64%

64%

64%

64%

POE

15%

15%

15%

15%

Al 2 o 3 whiskers

3%

5%

8%

-

ZnO whiskers

-

-

-

10%

talcum powder

17%

15%

12%

10%

coupling agent

1%

1%

1%

1%

[0084] Put the above raw materials into a high-speed mixer with a rotation speed of about 1000rpm and mix for 3 minutes. See Example 1 for the extrusion granulation process. Wherein the coupling agent used is the mixture of epoxy resin, hydrogenated butadiene and monoglyceride, 50% by weight of epoxy resin, 25% by weight of hydrogenated butadiene, and 25% by weight of monoglyceride.

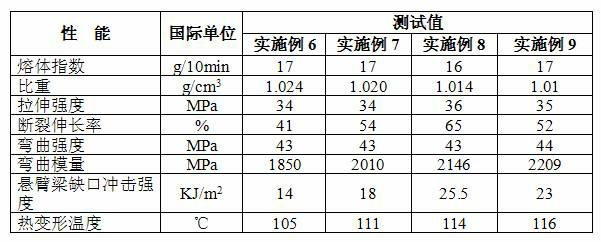

[0085] The properties of the prepared samples are as follows:

[0086] Table 6 Performance table

[0087]

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com