High heat resistance low density high performance auto polypropylene composite and preparation method thereof

A polypropylene composition, high heat-resistant technology, applied in the field of modified materials, can solve the problems of high heat resistance and high toughness, and achieve excellent comprehensive performance, light weight, and improve the effect of bonding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0064] Table 1 Formula content

[0065] components Example 1 Comparative example 1 Comparative example 2 Comparative example 3 PP 84.5% 85% 84.5% 84.5% POE 5% 5% 5% 5% al 2 o 3 whiskers 5% 5% 10% - coupling agent 0.5% - 0.5% 0.5% talcum powder 5% 5% - 10%

[0066] Put the above raw materials into a high-speed mixer with a rotation speed of about 1000rpm and mix them according to the weight percentage, and then put them into a twin-screw extruder. Get granulated. Wherein the coupling agent used is the mixture of epoxy resin, hydrogenated butadiene and monoglyceride, 50% by weight of epoxy resin, 25% by weight of hydrogenated butadiene, and 25% by weight of monoglyceride.

[0067] The properties of the prepared samples are as follows:

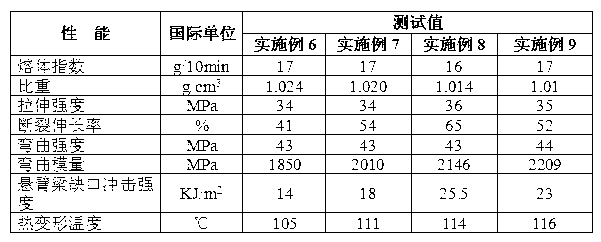

[0068] Table 2 Performance table

[0069]

[0070] Comparing Example 1 and Comparative Example 2 from Table 2, the embodiment of adding talcum powder and whisker compound...

Embodiment 2~ Embodiment 5

[0073] Table 3 Formula content

[0074] components Example 2 Example 3 Example 4 Example 5 Comparative example 4 PP 64% 64% 65% 58% 58% POE 15% 15% 10% 15% 10% Al 2 o 3 whiskers 3% 10% 13% 15% - coupling agent 1% 1% 2% 2% 2% talcum powder 17% 10% 10% 15% 30%

[0075] Put the above raw materials into a high-speed mixer with a rotation speed of about 1000rpm and mix for 3 minutes. See Example 1 for the extrusion granulation process. Wherein the coupling agent used is the mixture of epoxy resin, hydrogenated butadiene and monoglyceride, 30% by weight of epoxy resin, 40% by weight of hydrogenated butadiene, and 30% by weight of monoglyceride.

[0076] The properties of the prepared samples are as follows:

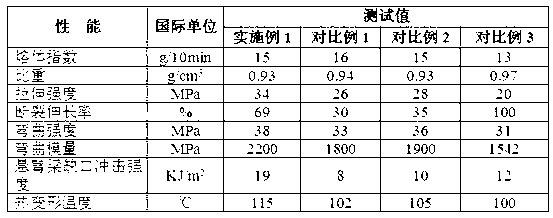

[0077] Table 4 Performance table

[0078]

[0079] Comparing Examples 2 to 5, it is found that the compounded talcum powder and whiskers can produce materials with different properties through ...

Embodiment 6~ Embodiment 9

[0081] Table 5 Formula content

[0082] components Example 6 Example 7 Example 8 Example 9 PP 64% 64% 64% 64% POE 15% 15% 15% 15% al 2 o 3 whiskers 3% 5% 8% - ZnO whiskers - - - 10% talcum powder 17% 15% 12% 10% coupling agent 1% 1% 1% 1%

[0083] Put the above raw materials into a high-speed mixer with a rotation speed of about 1000rpm and mix for 3 minutes. See Example 1 for the extrusion granulation process. Wherein the coupling agent used is the mixture of epoxy resin, hydrogenated butadiene and monoglyceride, 50% by weight of epoxy resin, 25% by weight of hydrogenated butadiene, and 25% by weight of monoglyceride.

[0084] The properties of the prepared samples are as follows:

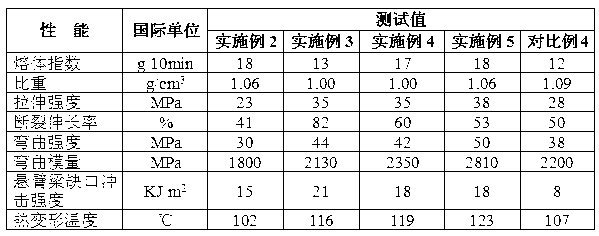

[0085] Table 6 Performance table

[0086]

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com