Method for mounting dismountable steel trestle

An installation method and technology of steel trestle bridges, applied in the direction of erecting/assembling bridges, bridges, bridge construction, etc., can solve a large number of large-scale construction machinery, difficult to popularize and apply problems, etc., achieve great promotion value, reduce dependence on the working environment, and site requirements not high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

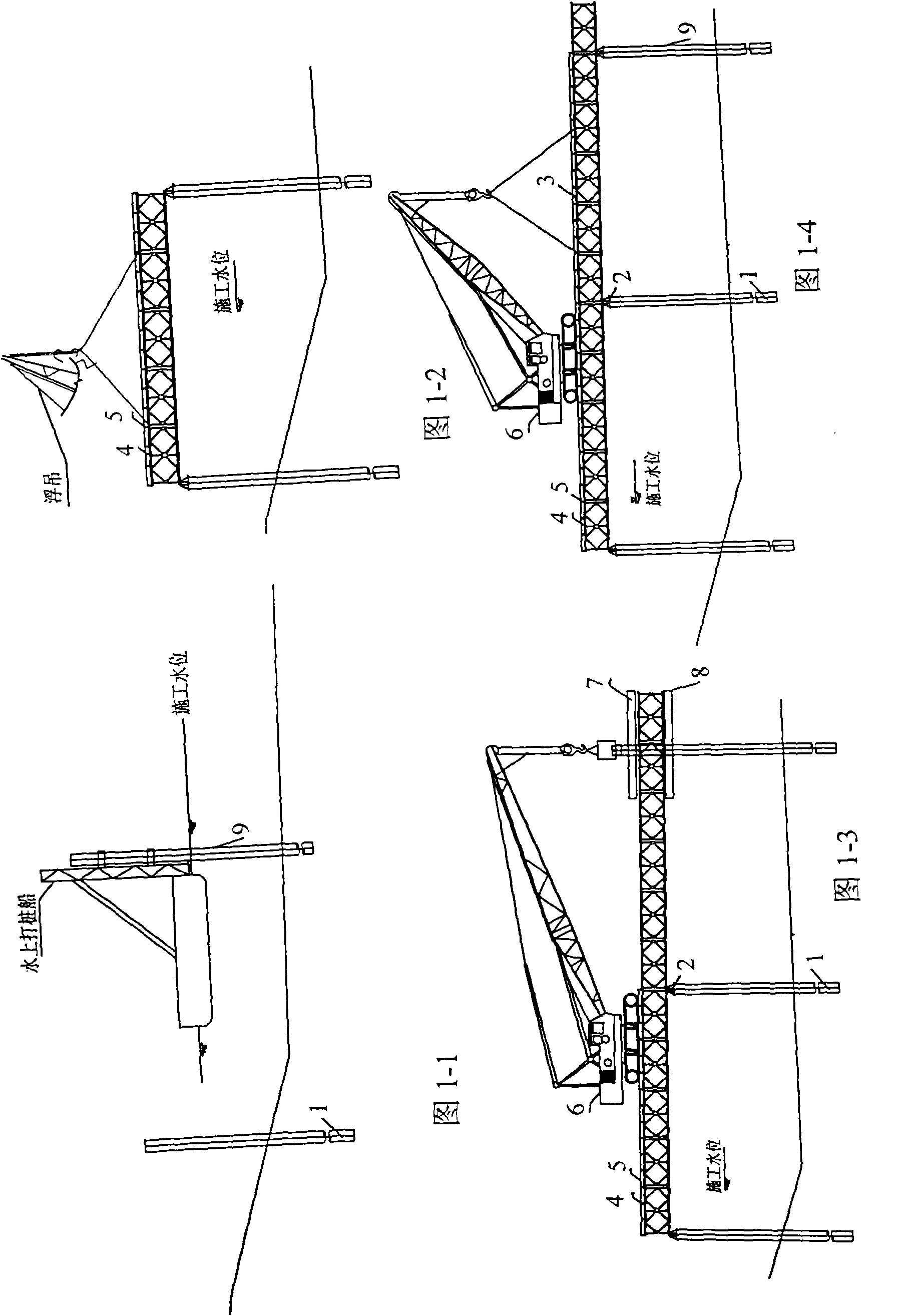

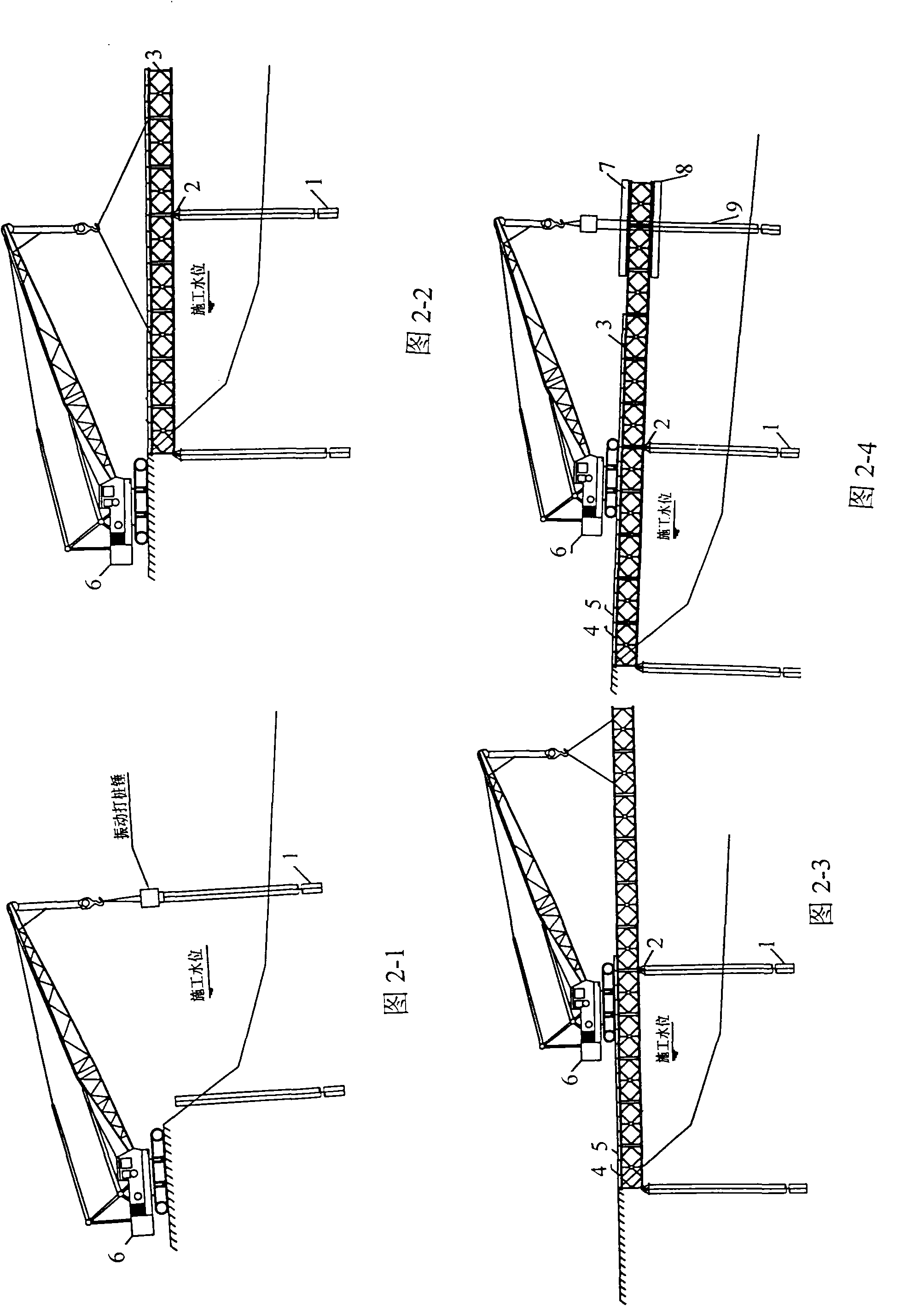

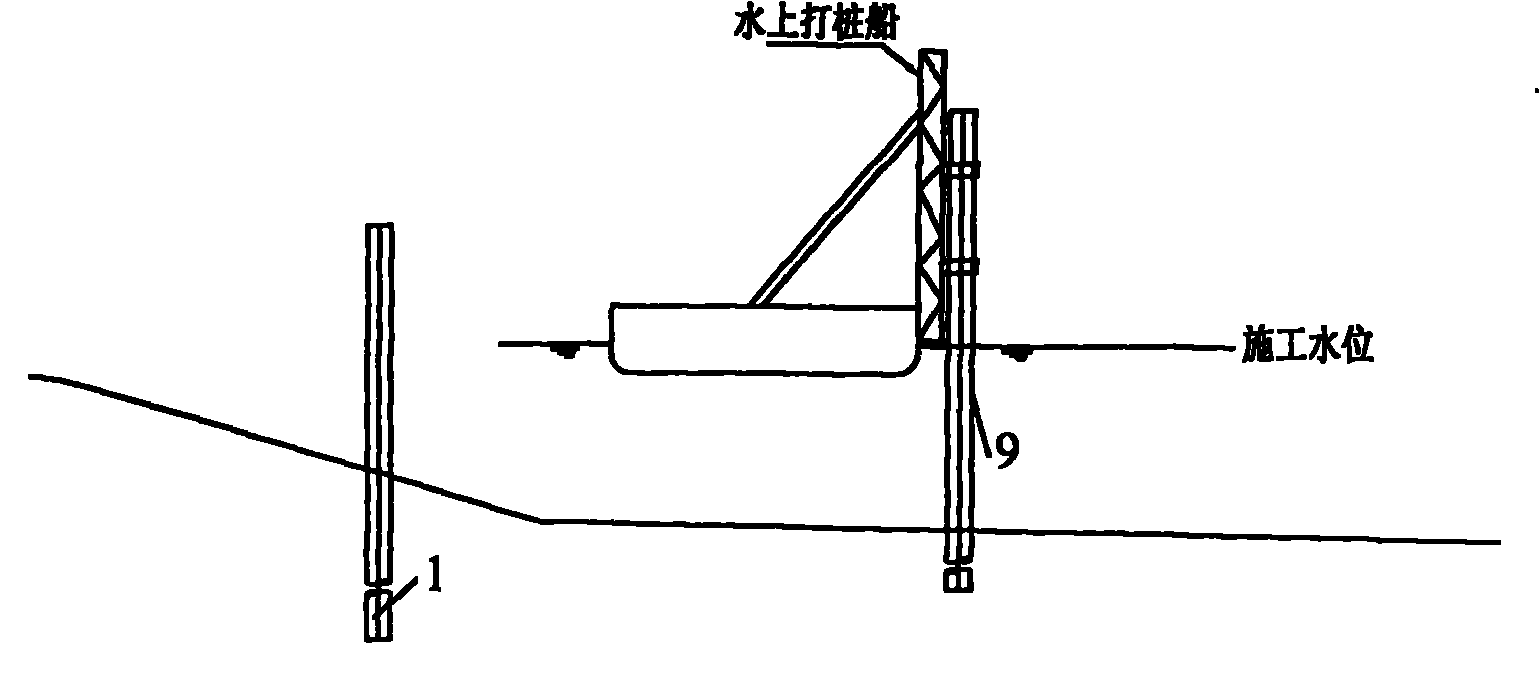

[0017] Control attached figure 1 , when constructing the Bailey beam steel trestle bridge from the water, the construction steps include: 1. In the deep water area, use the floating crane to insert and drive the first hole steel pipe pile. Picture 1-1 ; Two, install the Bailey beam truss at the first hole, and the bridge deck system can use the floating hanger to set up the Bailey truss beam at the first hole of the bridge such as Figure 1-2 ; 3. Floating crane to hang the crawler crane on the erected first hole bridge deck, the crawler crane can be used to hang the crawler crane on the bridge deck, and the floating crane can be used to install the guide beam, the guide frame, and the steel for hanging and inserting the pier. Pipe piles such as figure 1 -3; 4. Use the crawler crane to install the guide beam and the guide frame to hang and insert steel pipe piles to construct the steel trestle bridge hole by hole. You can use the Bailey truss beam installed in the next hole ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com