Omnidirectional interlocking slope protection building block and lapping interlocking method thereof

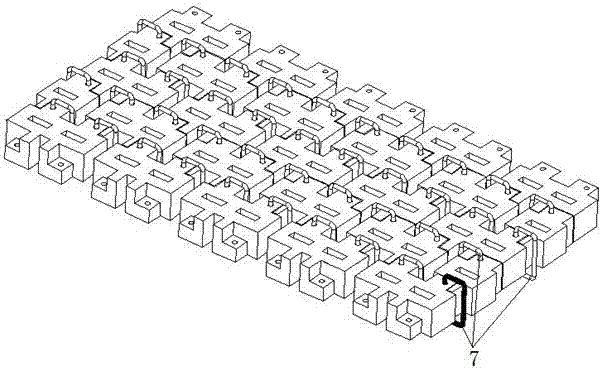

A block and lock-type technology, applied in coastline protection and other directions, can solve problems such as poor locking performance in the plane direction, uneven slope protection surface, increase engineering cost, etc., to achieve good water permeability, beautify the environment, and save materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the above-mentioned features and advantages of the present invention more comprehensible, the following specific examples are given in conjunction with the drawings, and detailed descriptions are made as follows.

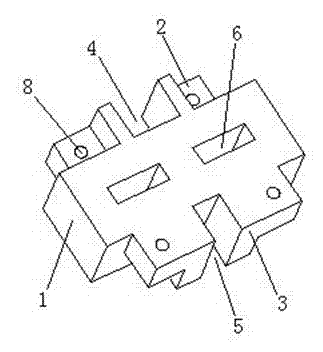

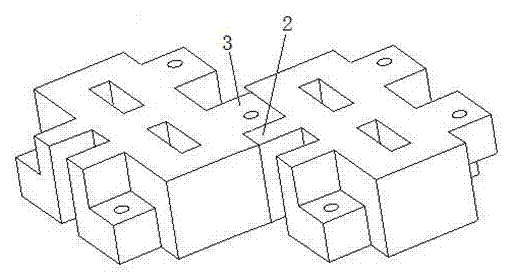

[0024] Please refer to figure 1 , An omni-directional interlocking slope protection block, comprising a rectangular body 1, characterized in that: the front side of the rectangular body 1 is provided with a pair of regular L-shaped lap plates 2 with the gaps facing each other and facing upwards. The back side of the body 1 is provided with a pair of inverted L-shaped lap plates 3 facing downwards with the gaps opposite to each other. The two positive L-shaped lap plates 2 and the two inverted L-shaped lap plates 3 are symmetrical about the center cross section of the rectangular body 1. , A first groove 4 is formed between the vertical lap sections of the two positive L-shaped lap plates 2, and a second groove 5 is formed between the vertical lap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com