FRP (fiber reinforce plastic) tube-concrete-steel tube combined tube tower and segmented construction method thereof

A construction method and concrete technology, which are applied in the field of buildings and their construction, can solve problems such as inconvenience in the construction of pipe towers, and achieve the effects of rapid construction, ensuring beautiful appearance and improving structural performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

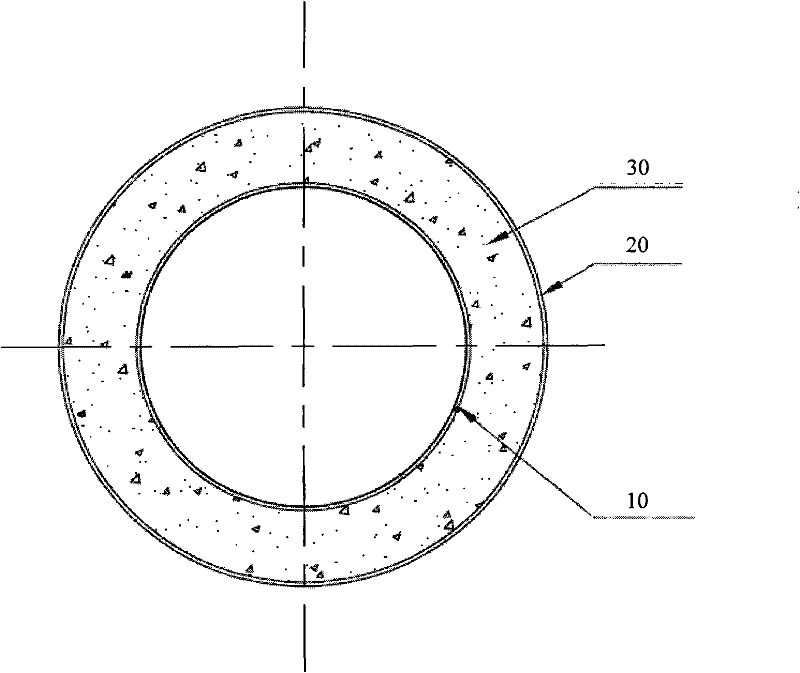

[0039] see figure 1 , figure 1 It is a cross-sectional view of the FRP pipe-concrete-steel composite pipe tower of the present invention. Such as figure 1 As shown, the FRP pipe-concrete-steel pipe composite pipe tower provided by the present invention is mainly composed of a steel inner pipe 10 formed by connecting multiple steel pipe sections, an FRP outer pipe 20 formed by connecting multiple FRP pipe sections, and pouring between the two Concrete layer 30 in between. It should be noted, figure 1 The steel inner tube 10 and the FRP outer tube 20 are shown as circular, but the two tubes can also be of other shapes (such as square), or different shapes (such as the outer tube is a square tube and the inner tube is a round tube). Both the steel pipe segment and the FRP segment can be prefabricated in the factory, and can also be constructed on the construction site of the FRP pipe-concrete-steel pipe composite tower.

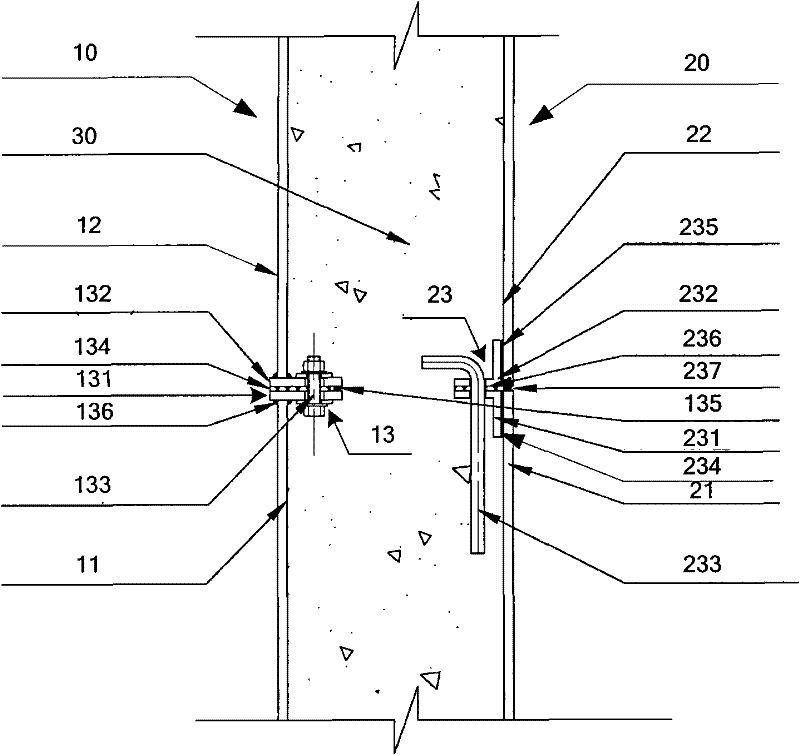

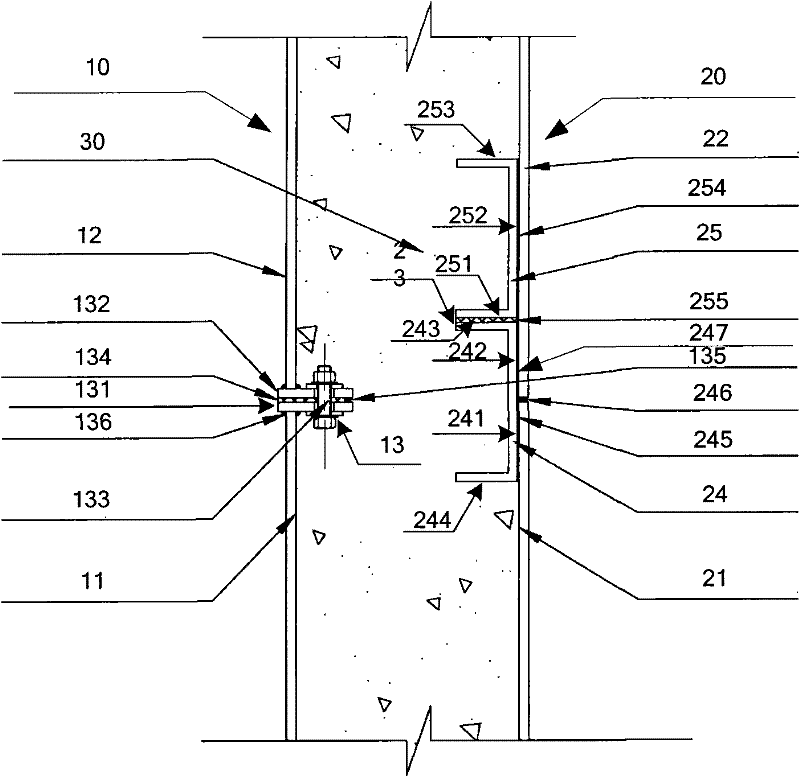

[0040] It is worth mentioning that the adjacent steel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com