Muffling tail pipe with decorative pipe

A technology for exhaust tail pipes and decorative pipes, which is applied in the direction of mufflers, exhaust devices, engine components, etc. It can solve the problems of unfavorable vehicle vibration, acoustic roughness, and chassis space occupation, and achieve simple structure and low gas flow rate , Reduce the effect of exhaust back pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further explained below in conjunction with the drawings.

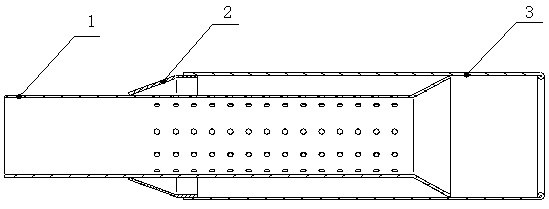

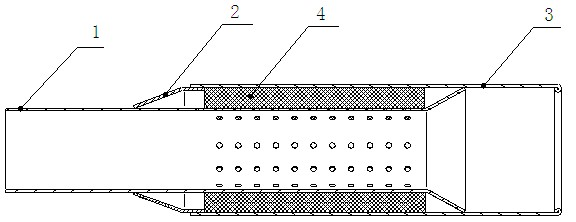

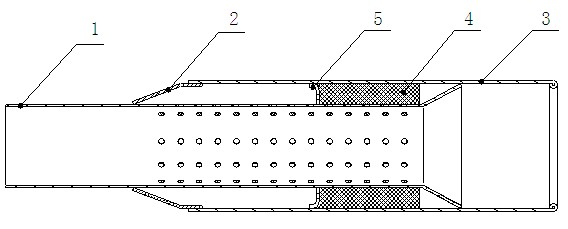

[0012] See figure 1 , The exhaust tail pipe with decorative pipe includes the tail pipe 1, the end cover 2 and the decorative pipe 3. The tail end of the exhaust tail pipe 1 is made into a bell mouth, which is inserted into the decorative pipe 3, and the exhaust tail pipe 1 is inserted The part of the decorative pipe 3 is provided with a number of uniformly distributed small holes. The large mouth end face of the exhaust tail pipe 1 is welded to the inner wall of the decorative pipe 3 to form a seal. The end cap 2 is placed on the front end of the decorative pipe and fitted on the exhaust tail pipe. , The edge of the inner ring is welded and sealed with the outer wall of the tail pipe, and the edge of the outer ring is welded and sealed with the decorative pipe. The outer wall of the part where the tail pipe 1 is inserted into the decorative pipe 3 and the end cap 2 and the inner wall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com