Exhaust device of rolling rotor compressor pump body

A rolling rotor type, compressor pump technology, applied in parts of pumping devices for elastic fluids, rotary piston type/oscillating piston type pump parts, machines/engines, etc. Less application and other problems, to achieve the effect of easy processing and assembly, simple bending process and easy realization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

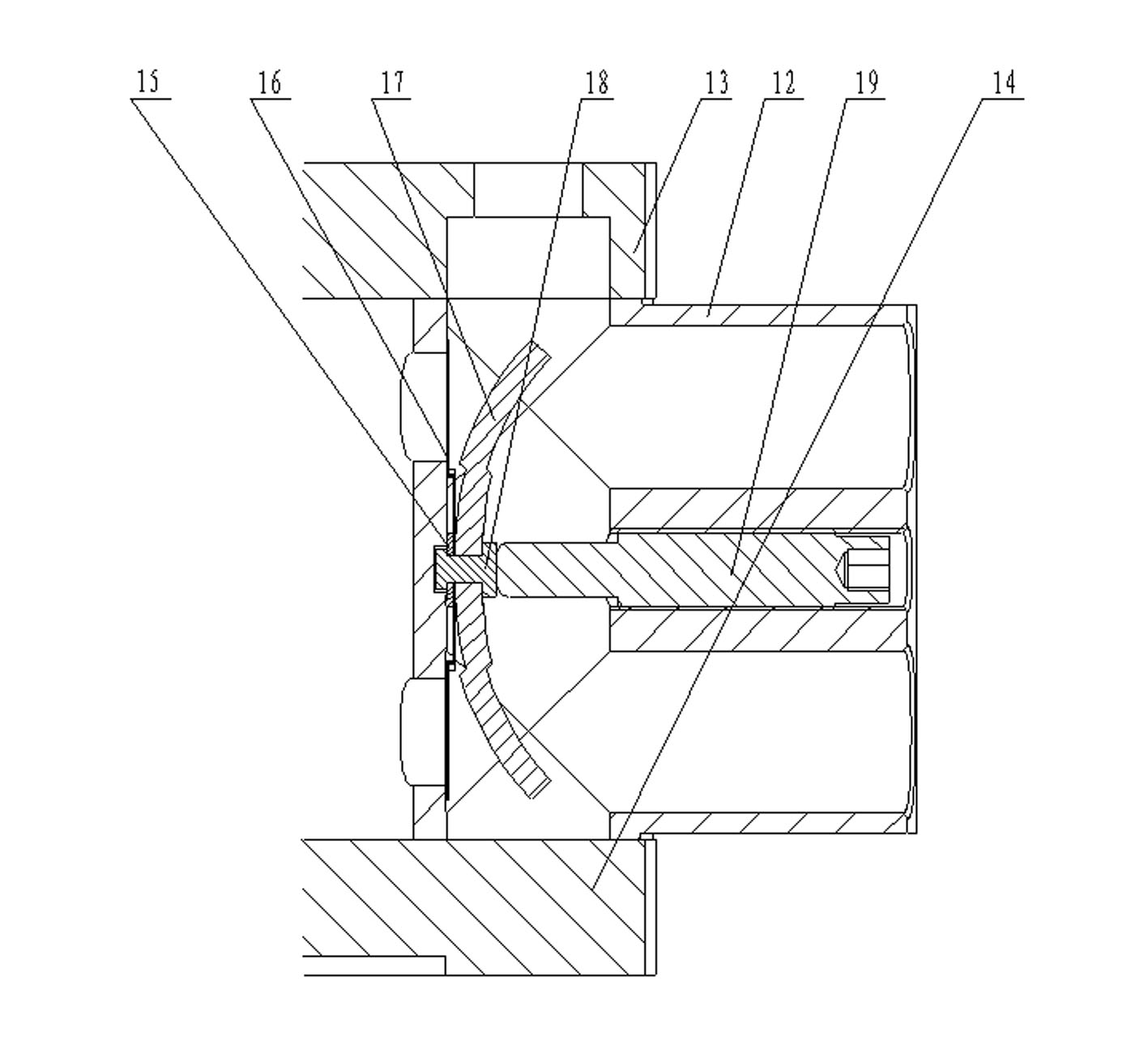

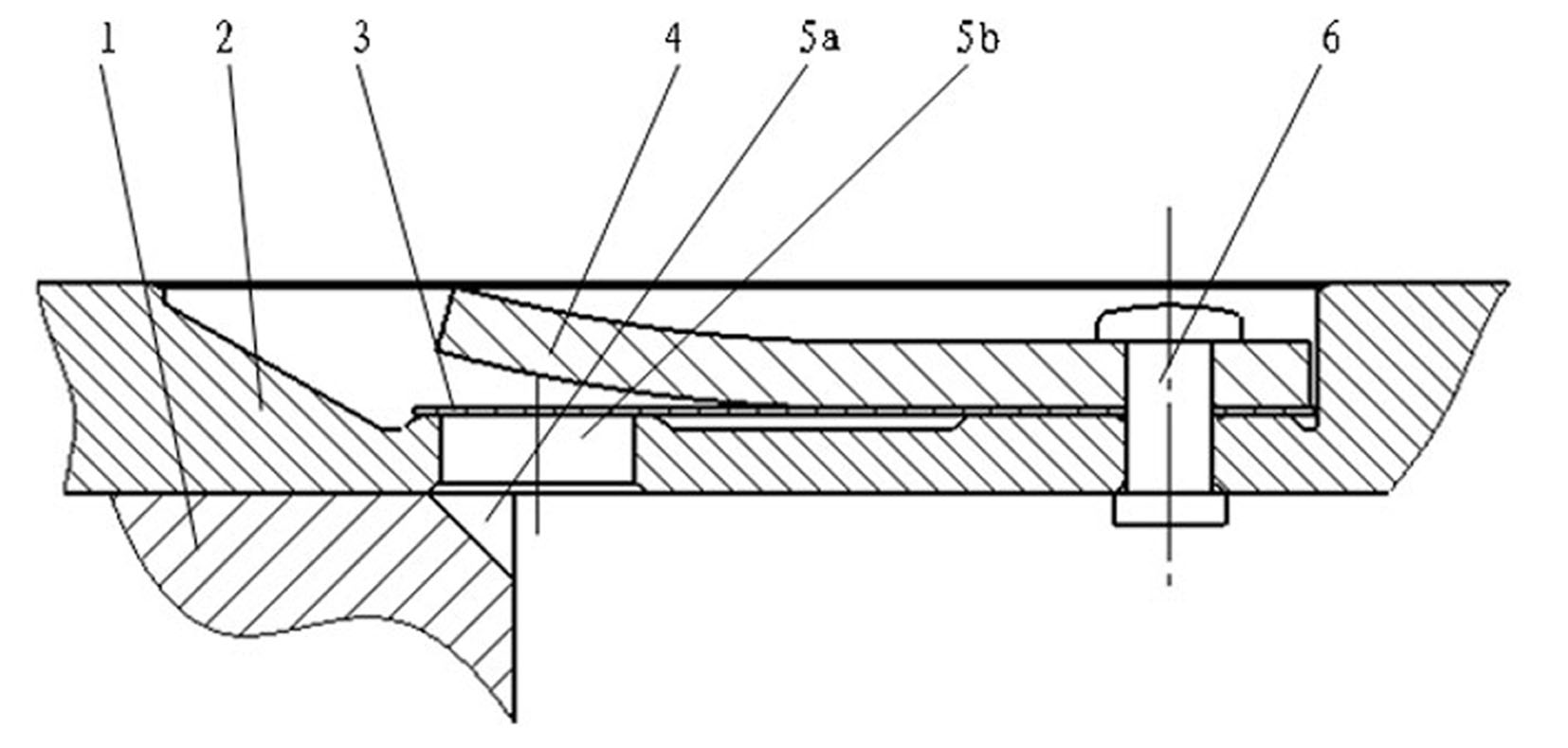

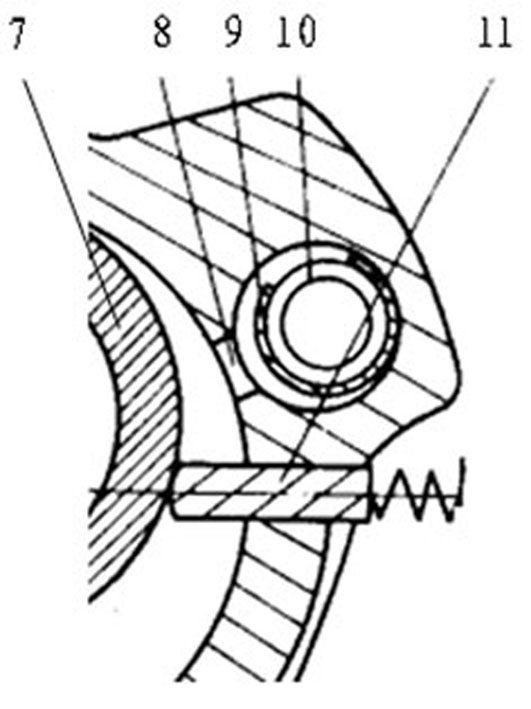

[0037] The present invention will be further described below in conjunction with drawings and embodiments.

[0038] Such as image 3 , Figure 4 As shown, the pump body exhaust device provided by the present invention includes a cylinder 12 , a valve plate 16 , a lift limiter 17 , an upper end cover 13 of the cylinder, a lower end cover 14 of the cylinder, a gasket 15 , a rivet 18 and a push rod 19 . A circular exhaust hole 21 and an installation hole 22 are processed on the cylinder wall of the exhaust device, and the valve plate 16, the lift limiter 17, and the gasket 15 are installed and fixed on the installation hole of the cylinder 12 with a rivet 18 and a push rod 19 22; the valve plate 16 and the lift limiter 17 are axially installed parallel to the cylinder 12, and the sealing surface 23 of the valve plate and the installation and fixing surface 24 are both flat when at rest; after the compressor is assembled, the upper end cover 13 of the cylinder and the lower end c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com